Boiler convection heating surface vibratory-hitting type deashing device and vibratory-hitting method

A soot cleaning device and heating surface technology, which is applied to combustion methods, solid residue removal, lighting and heating equipment, etc., can solve problems such as inability to clean up in time, difficult ash cleaning, increased heat loss, etc., and achieve compact structure and airtight performance Good, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

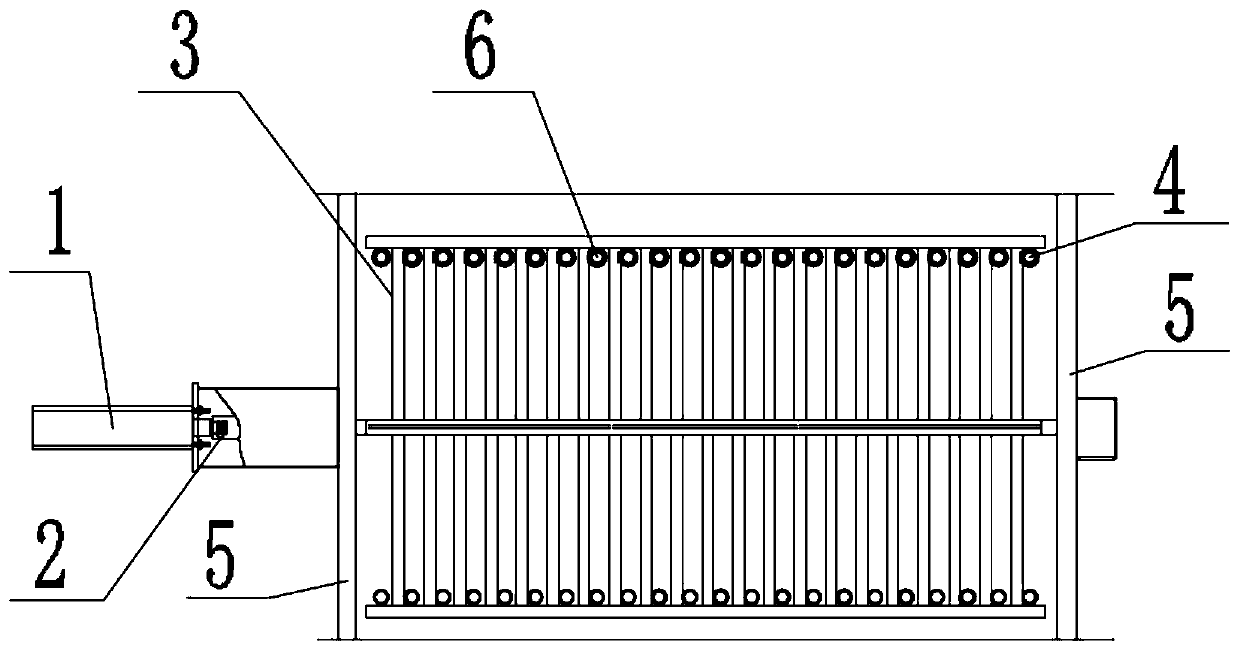

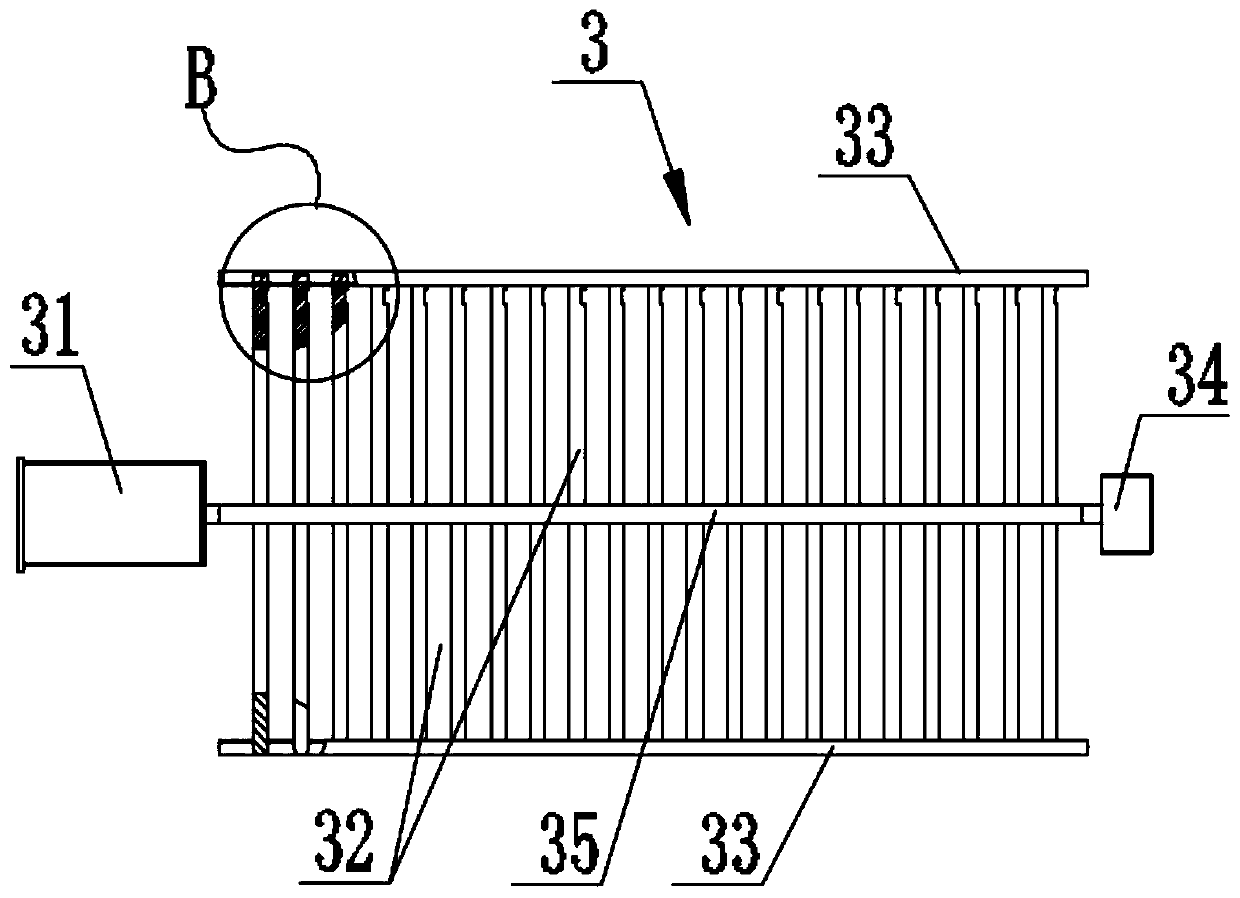

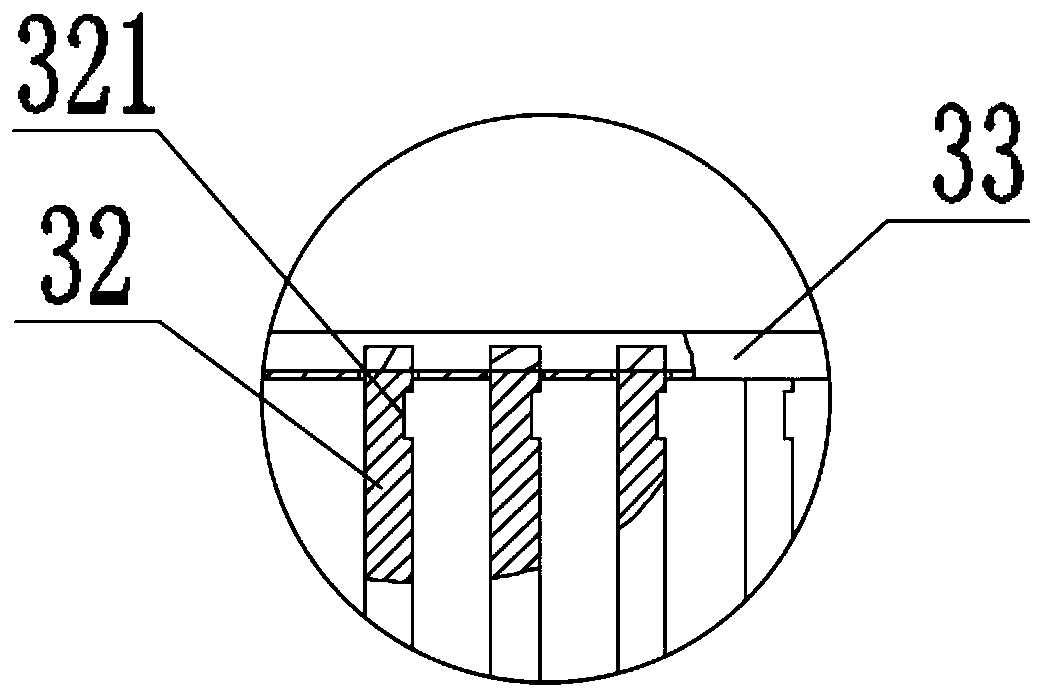

[0035] Such as Figure 1-Figure 3 As shown, the boiler convection heating surface rapping soot cleaning device of the present embodiment includes a rapping support 3, which is welded into an integral frame structure, and the middle part is provided with a support shaft 35 with one end connected to the vibrating device. 35 is provided with a plurality of vertical rods 32 at intervals in the axial direction, and the plurality of vertical rods 32 are arranged symmetrically with the support shaft 35 as the axis. Two hanging rods 33 hang the rapping support 3 on the tube bundle 4 on the heating surface of the boiler, so that each vertical rod 32 is in contact with the tube bundle 4 on the heating surface of the boiler.

[0036] The two ends of the support shaft 35 are respectively connected to the guard plates 5 at both ends of the heating sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com