A method for in-situ observation of liquid nitrogen frozen rock microstructure

A microstructure and liquid nitrogen freezing technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of water-sensitive water lock reaction, high crack initiation pressure, low rock breaking efficiency of hot dry rock reservoirs, etc., and achieve image High resolution, simple sample preparation, and adjustable magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

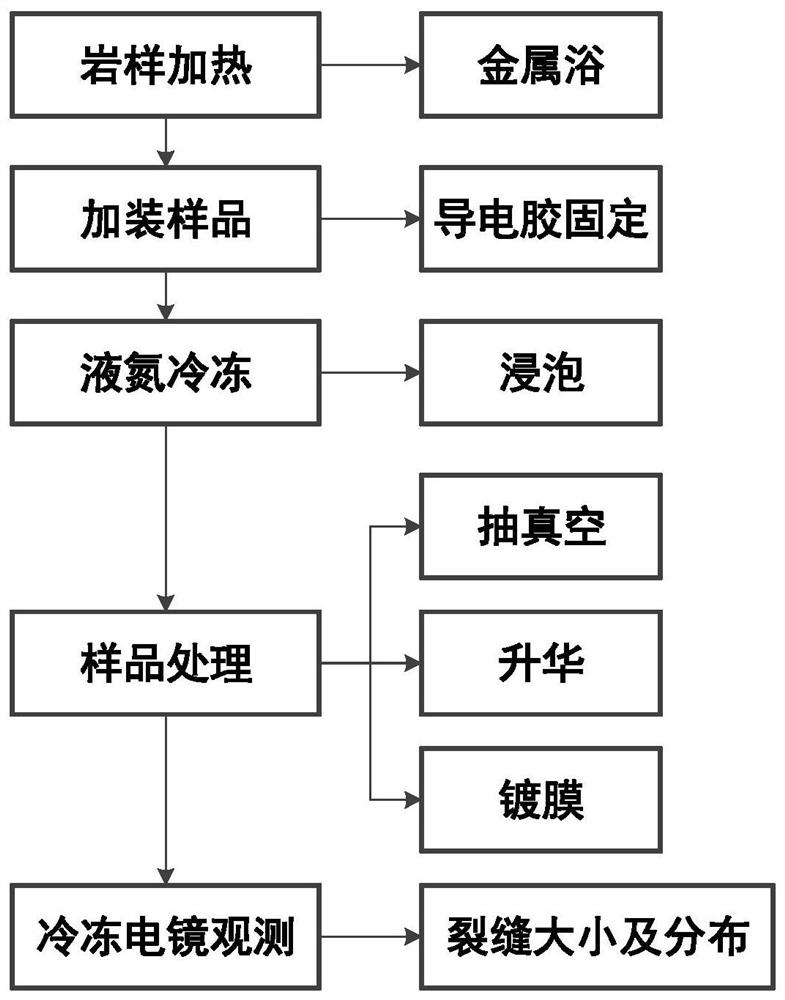

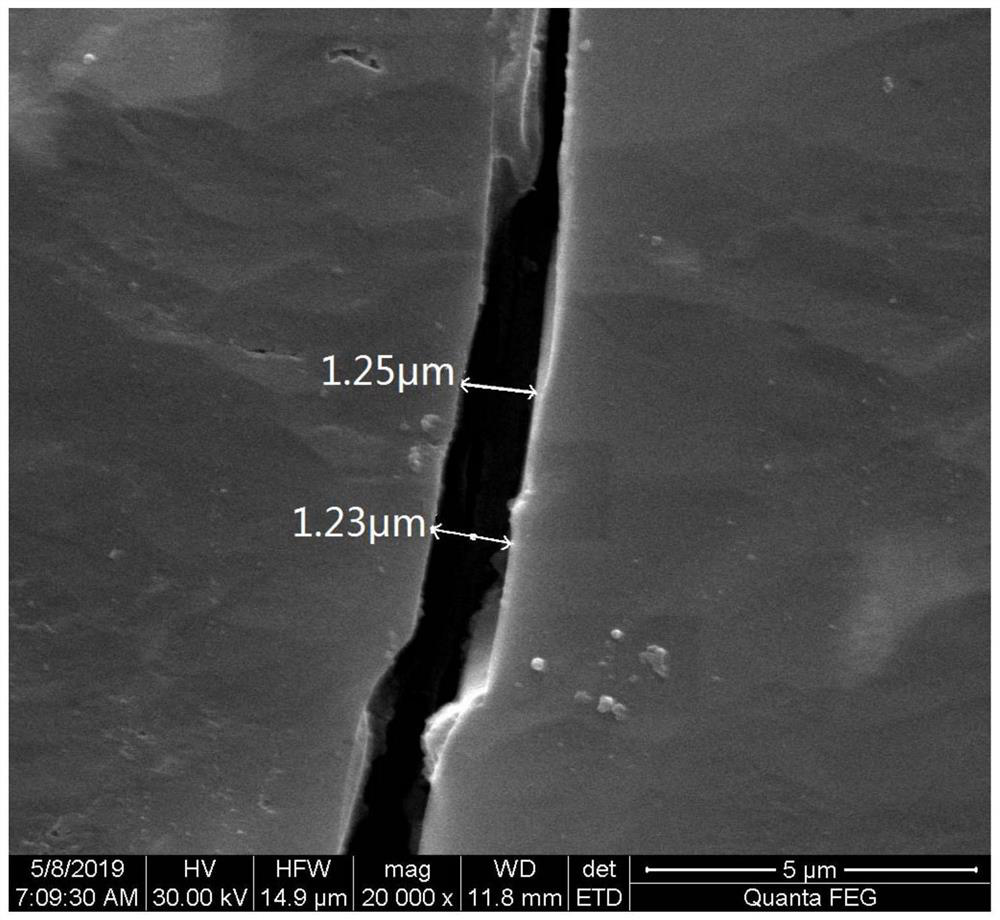

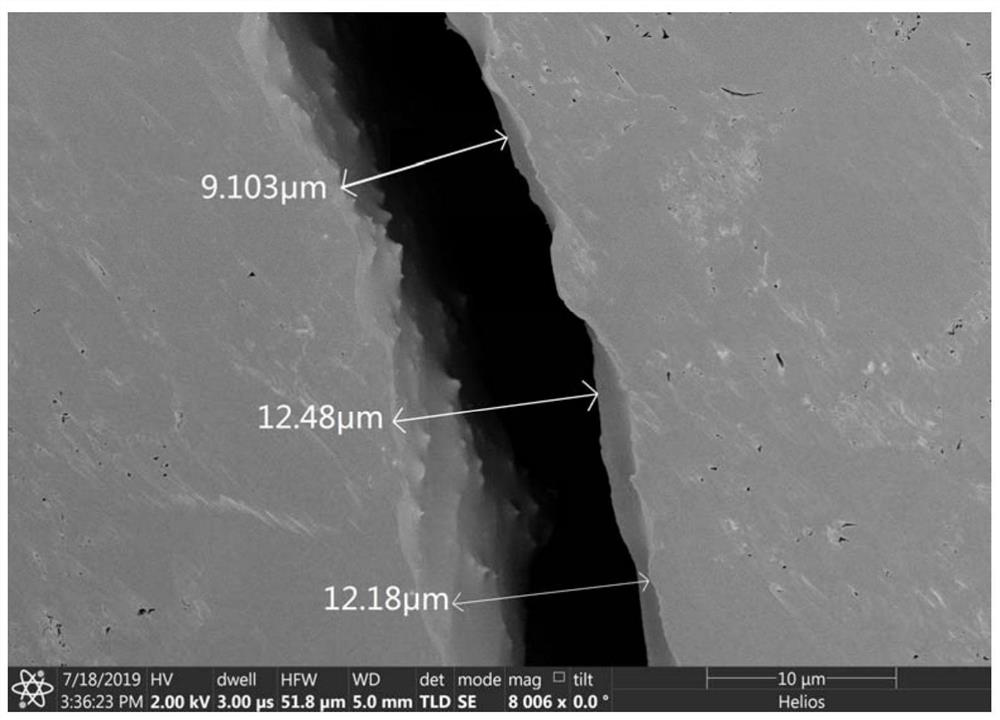

[0047] The liquid nitrogen frozen rock microstructure in-situ observation method of the present invention, such as figure 1 As shown, the following steps are included: (1) put the sliced polished coal into the digital display heating mantle, and heat it to 50°C; (2) take it out after the rock sample is heated evenly, soak it in liquid nitrogen until the internal temperature field Reach stability; (3) Take the rock sample out of liquid nitrogen and fix it on the loading disk with conductive glue; (4) Carry out vacuum treatment, sublimation treatment and coating treatment in sequence; (5) Send the sample into the cryo-electron microscope observe.

[0048] The size of the sliced and polished rock sample is 6mm×6mm×1.5mm. Four rock samples of this size can be placed on the cryo-electron microscope loading disk for observation at a time. After one sample is observed, the next one can be observed by moving the lens position, which can save sample preparation. time.

[0049] Ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com