Highly waterproof liquid crystal display screen assembly

A liquid crystal display and liquid crystal display technology, which is applied in the direction of electrical components, electrical equipment structural parts, instruments, etc., can solve problems that affect the normal operation of electronic components, affect the normal operation of liquid crystal displays, short circuit or rust of electronic components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

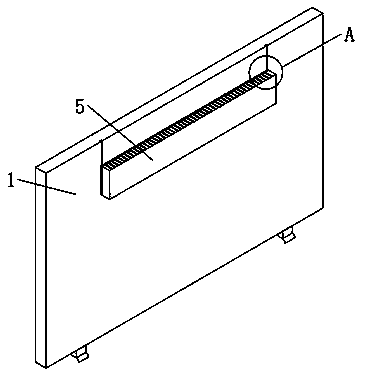

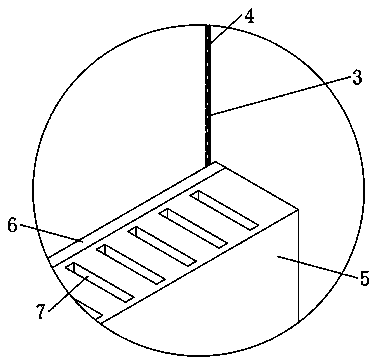

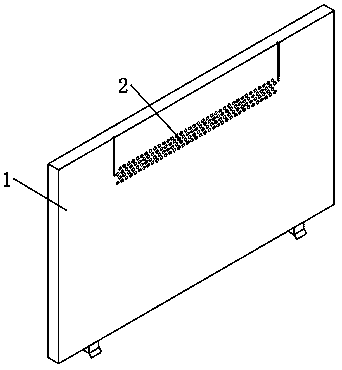

[0032] see Figure 1-5 and Figure 7-8, a highly waterproof liquid crystal display assembly, comprising a liquid crystal display main body 1, a display cooling hole 2 is dug on the liquid crystal display main body 1, and a waterproof box 5 matching the display cooling hole 2 is provided on one side of the liquid crystal display main body 1, The upper end of the waterproof box 5 is dug with a through hole 7, and the liquid crystal display main body 1 is dug with a T-shaped chute 3, and the end of the waterproof box 5 close to the liquid crystal display main body 1 is fixedly connected with a sealing gasket 6 matching the T-shaped chute 3 , the liquid crystal display main body 1 and the waterproof box 5 are slidingly connected through the T-shaped chute 3 and the T-shaped slider 8, and the waterproof box 5 is fixedly connected with a partition plate 9, and the partition plate 9 divides the inside of the waterproof box 5 into fixed parts. There are two parts, the fixed cavity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com