Double-layer machining line of concrete components and machining method of double-layer machining line

A concrete and processing line technology, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of high efficiency, low space utilization, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

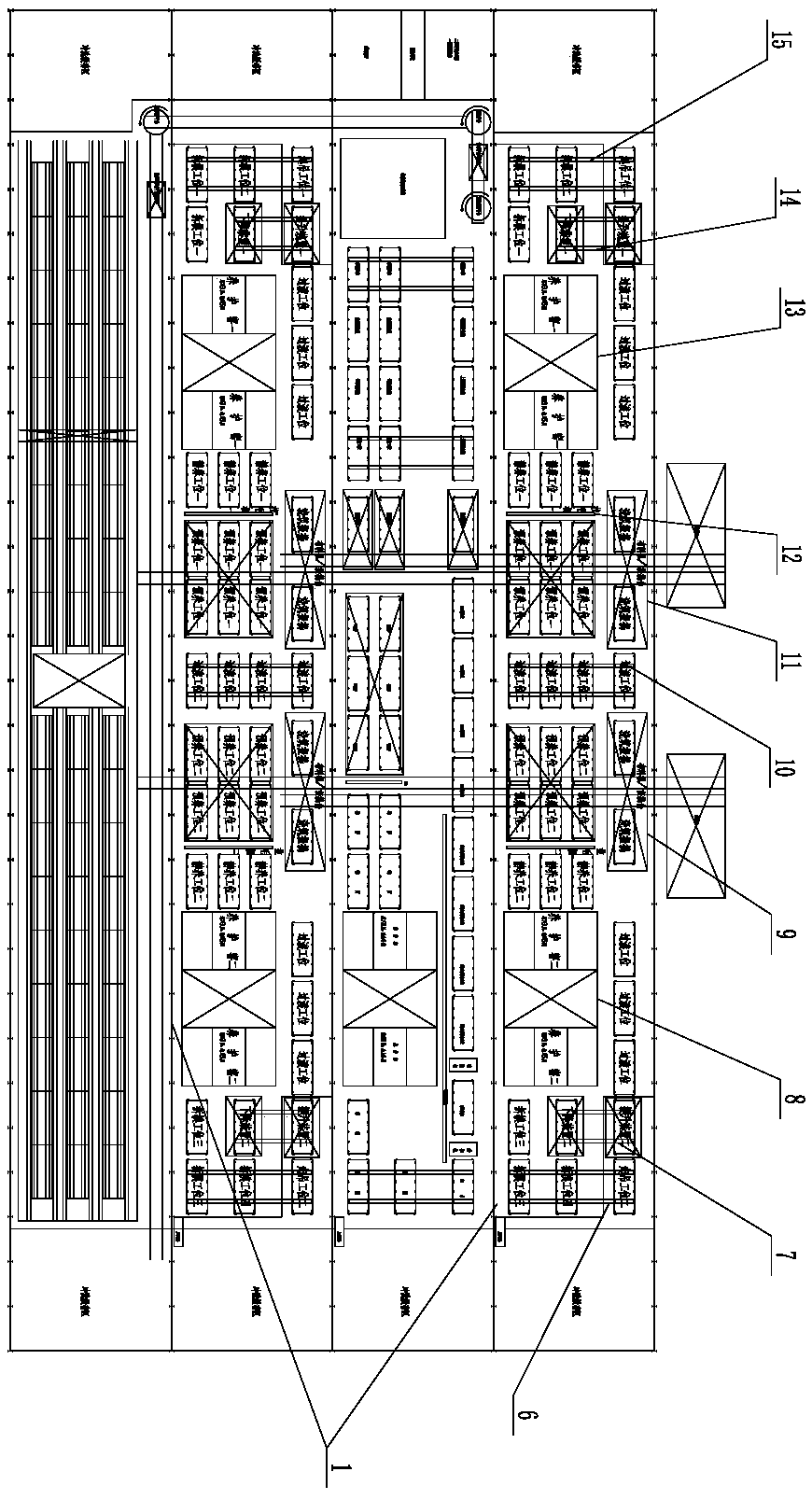

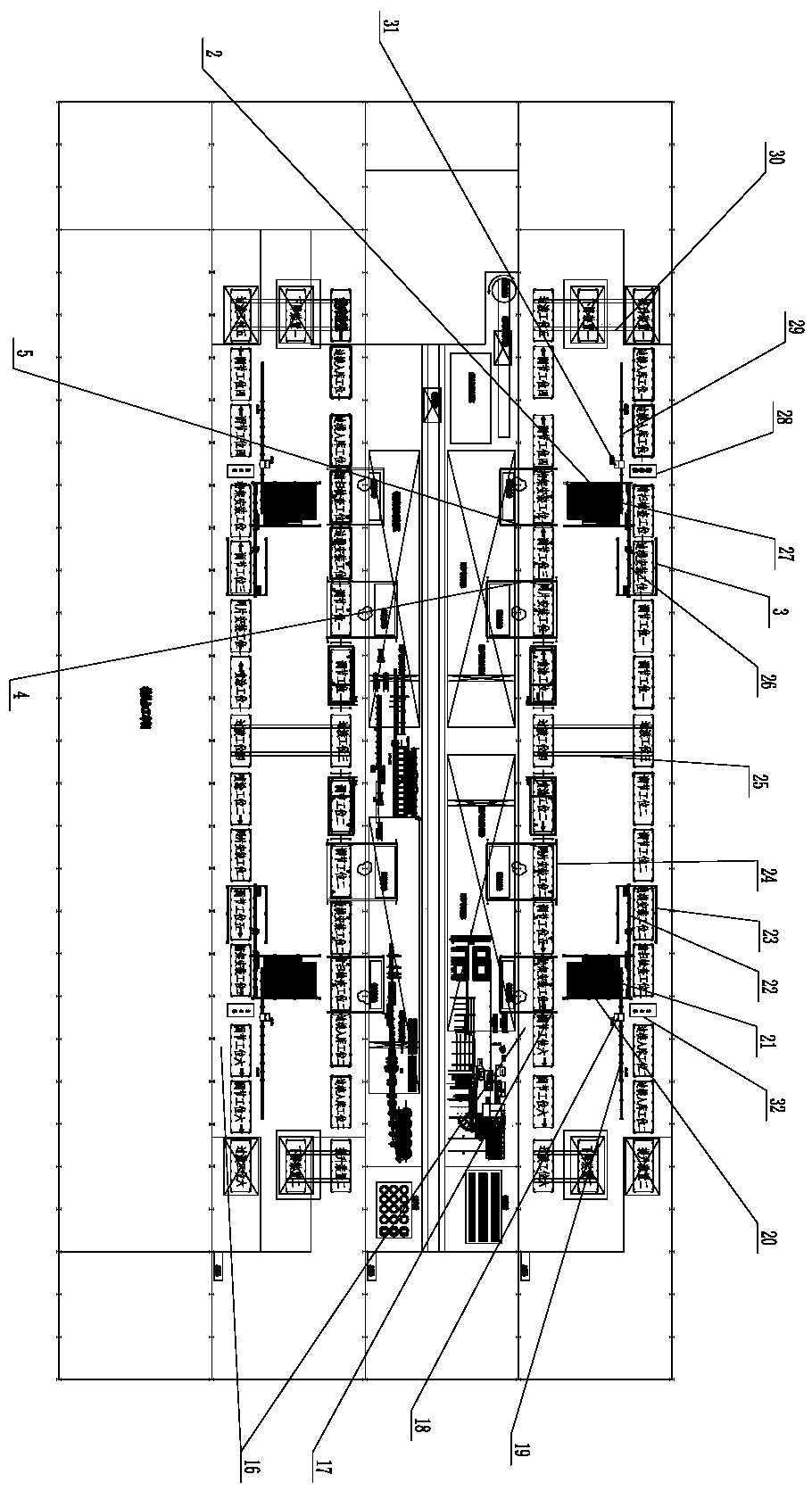

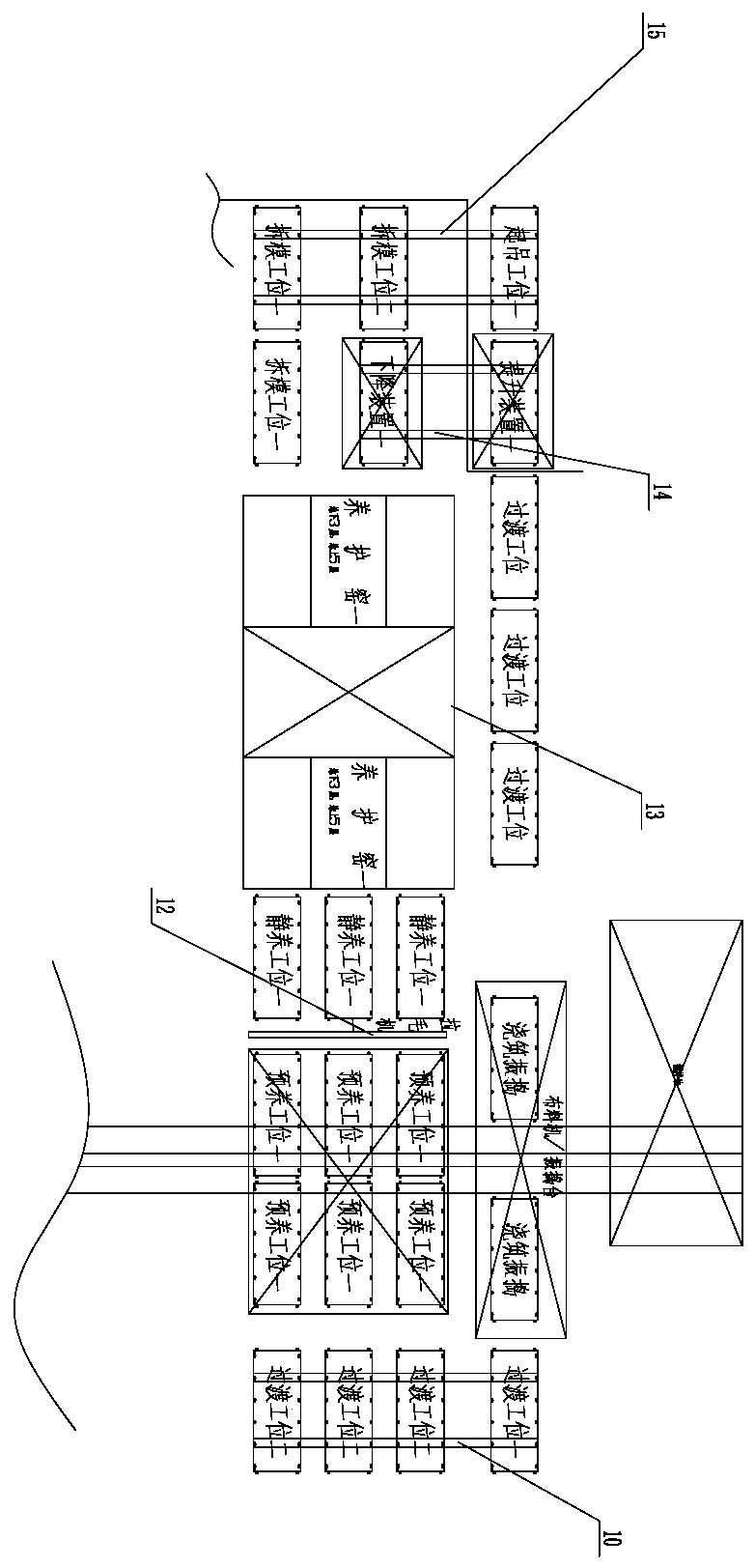

[0089] The present invention will be further described below with reference to the accompanying drawings.

[0090] like Figure 1 to Figure 47 Shown is a double-layer processing line for concrete components, including a first workshop and a second workshop, the second workshop is directly above the first workshop, and the first workshop is provided with two rows of forming lines spaced in the front-rear direction 1. The forming line 1 includes a distribution machine 1 11 and a distribution machine 2 9. The positions of the distribution machines on the left and right sides correspond to the distribution station 1 and the distribution station 2. There are adjustable The shuttle car 1 10 that moves back and forth and can lift the mold table, the direction of the front and rear movement of the shuttle car 10 is provided with a transition station 1 and at least one transition station 2, and the poured mold table is transferred to the transition station 1. The left and right sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com