Unmanned aerial vehicle electric cabin composite cephalic cone integrated forming tool and process

A composite material and forming tooling technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve problems such as insufficient operating space and difficult operation of female molds, and achieve the effect of ensuring assembly accuracy and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

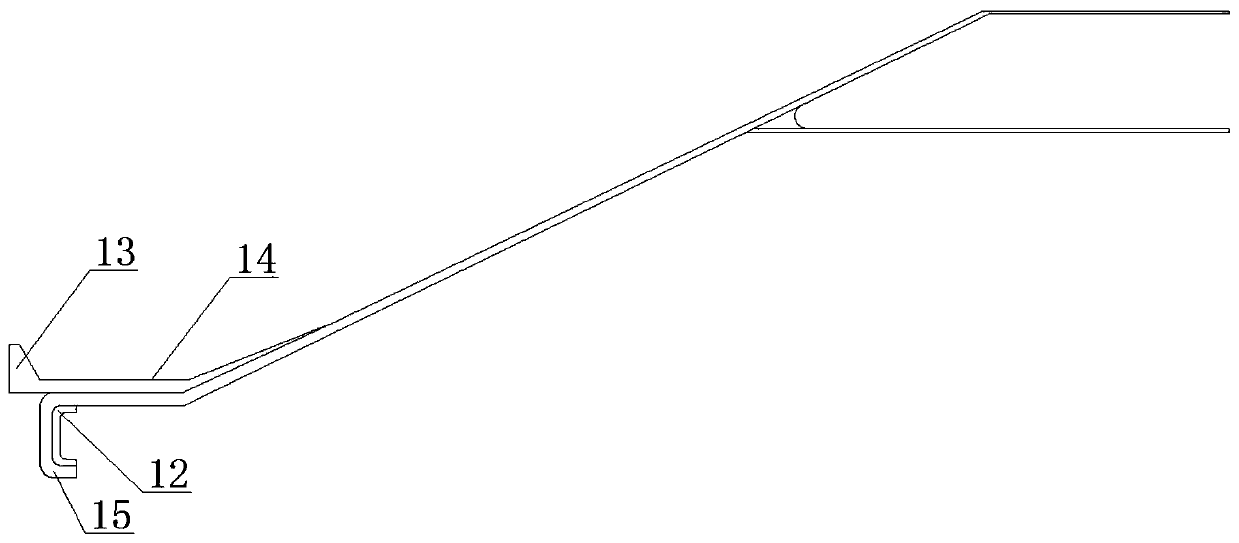

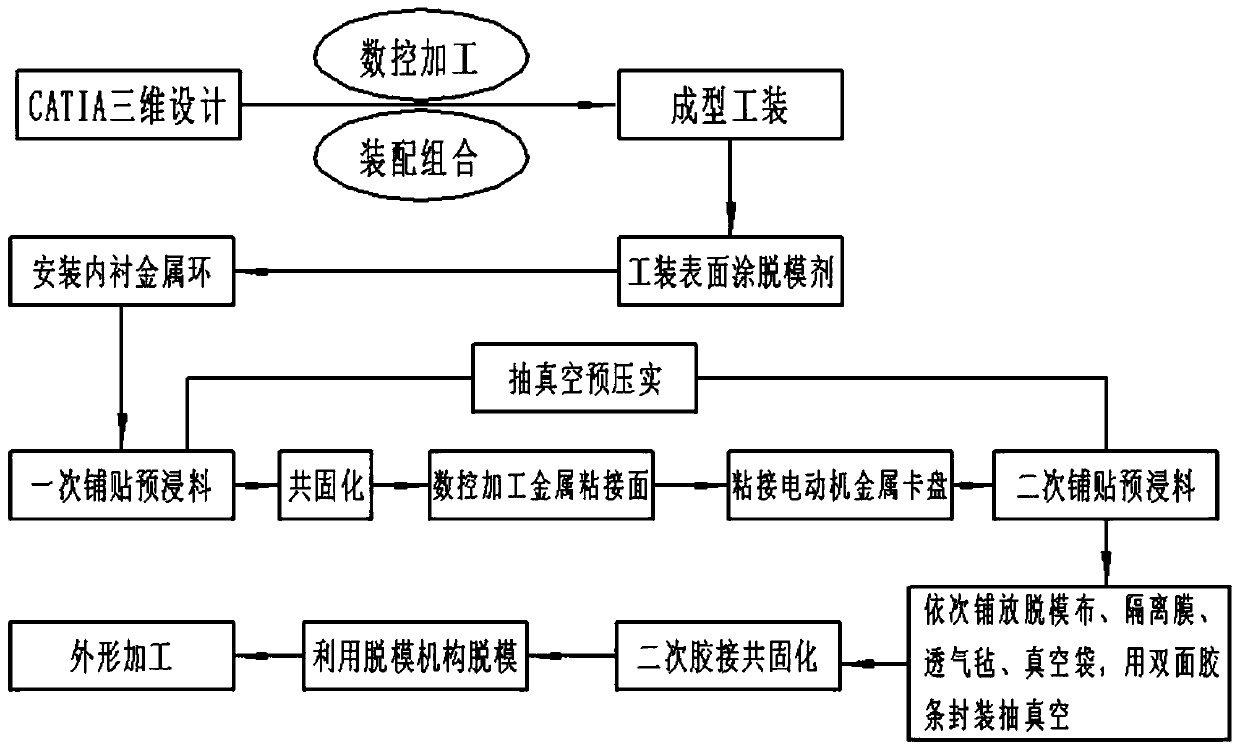

[0036] As a preferred embodiment of the present invention, the forming tooling manufactures metal male molds and related assembly components according to product precision requirements, and combines three coordinates to ensure assembly accuracy, and prepares qualified composite nose cones 15 with the forming tooling.

[0037] As a preferred embodiment of the present invention, in the step 2 and step 3, the requirements for the paving environment are as follows: the temperature is 22°C±4°C, the humidity is 30%-65%, and the indoor cleanliness should reach ≥10μm of dust particles No more than 10 pieces / L; the pre-compaction vacuum pressure is ≥0.09MPa, and the time is 30 minutes.

[0038] As a preferred embodiment of the present invention, in the step 2 and step 3, the number of layers of carbon fiber prepreg is 20 layers.

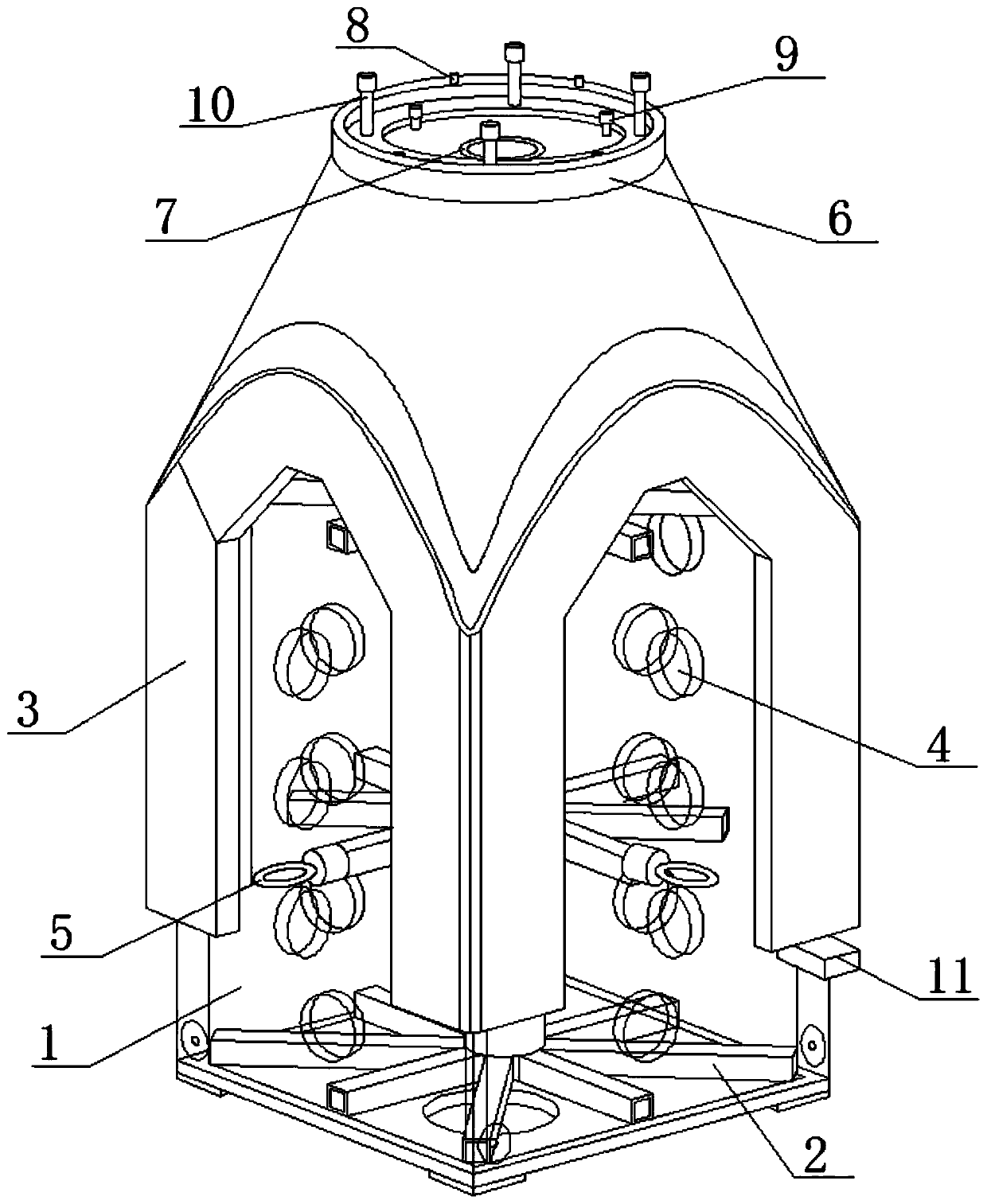

[0039] As a preferred embodiment of the present invention, the male model surface 1 , the inner square tube support 2 , the inner central circular tube suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com