Preparation method of industrial cleaning agent

A cleaning agent and industrial technology, applied in the field of industrial cleaning agent preparation, can solve the problems of limited removal of waste water by cleaning agents, complicated operation, poor sewage treatment effect of cleaning agents, etc., to improve the scope of sewage purification, promote movement and improve sewage purification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

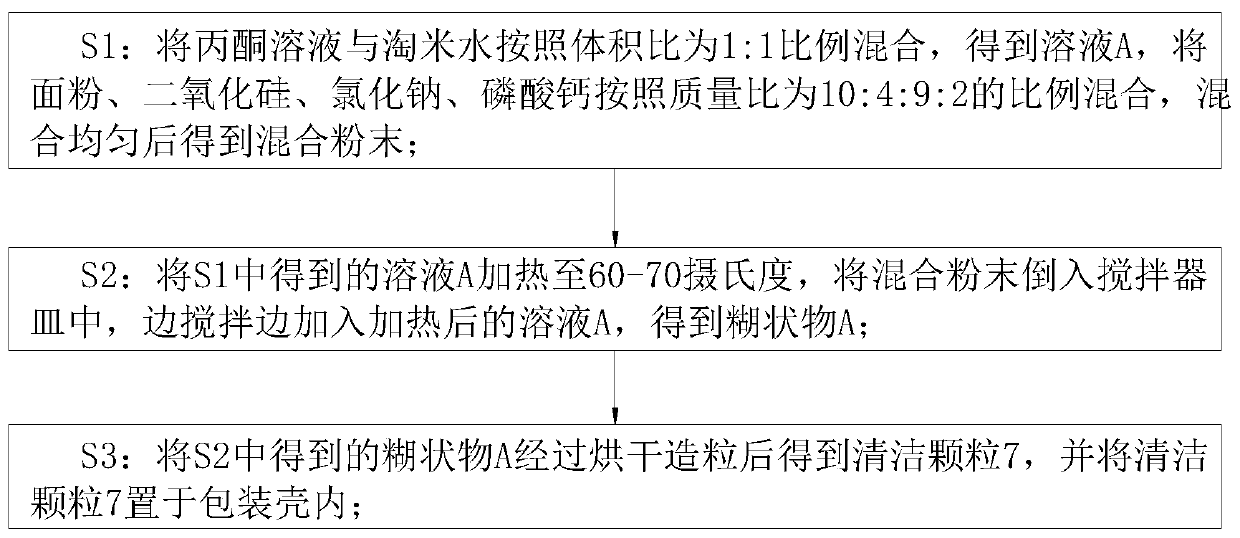

[0026] Such as Figure 1-Figure 3 Shown, the preparation method of a kind of industrial cleaner of the present invention comprises the following steps:

[0027] S1: Mix acetone solution and rice washing water at a volume ratio of 1:1 to obtain solution A, and mix flour, silicon dioxide, sodium chloride, and calcium phosphate at a mass ratio of 10:4:9:2 , to obtain mixed powder after mixing evenly;

[0028] S2: Heat the solution A obtained in S1 to 60-70 degrees Celsius, pour the mixed powder into a stirring vessel, and add the heated solution A while stirring to obtain a paste A;

[0029] S3: The paste A obtained in S2 is dried and granulated to obtain cleaning granules 7, and the cleaning granules 7 are placed in the packaging shell; through the cleaning granules 7 with flour and rice washing water as the main raw materials, cleaning In the process of sewage treatment and purification, the cost of sewage treatment is greatly reduced, and flour and rice washing water are bio...

Embodiment approach

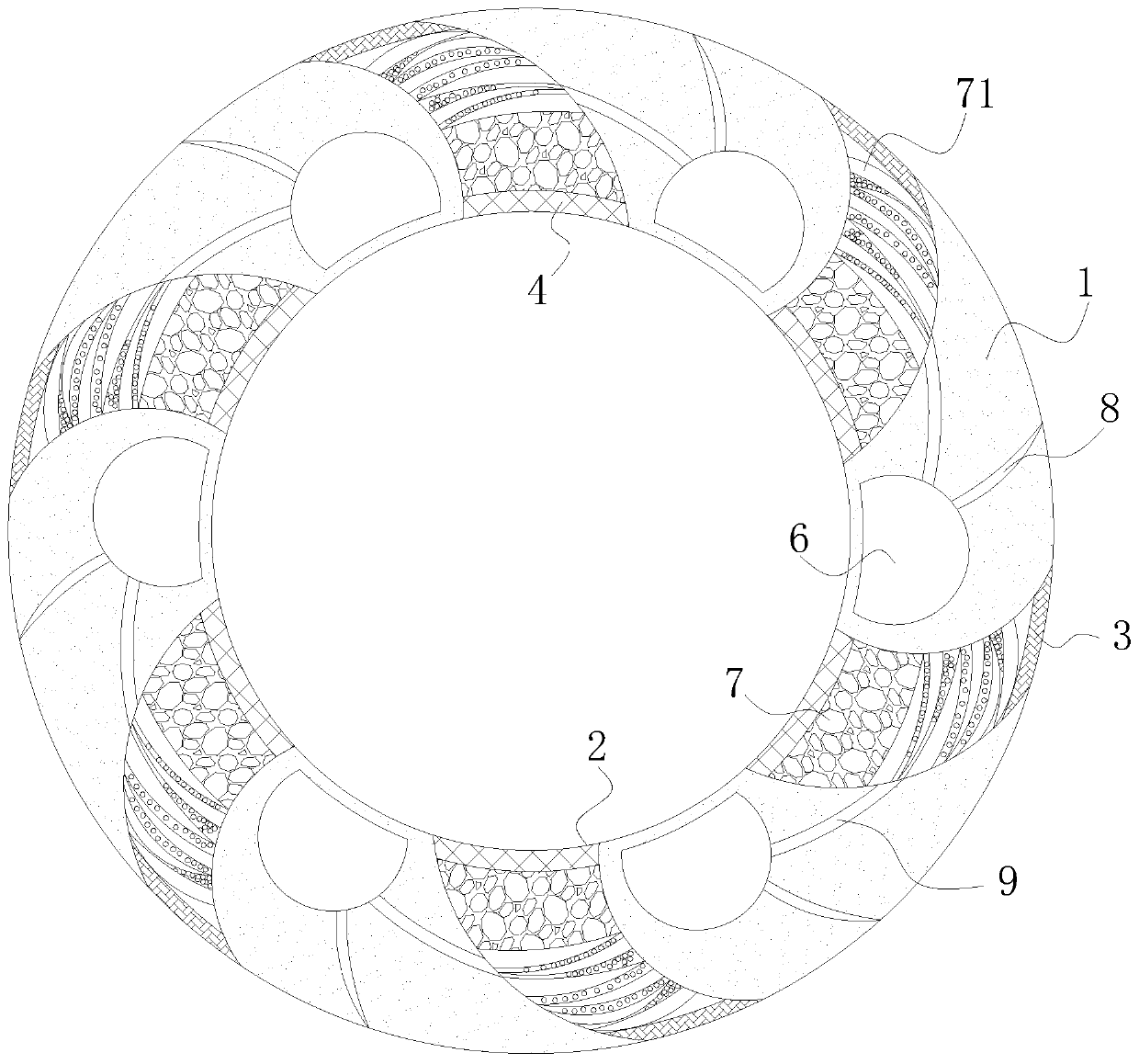

[0031] As an embodiment of the present invention, the side of the cleaning particles 7 in the filling tank away from the sealing net 4 is filled with cleaning tea leaves 71 in the filling tank 2, and the cleaning tea leaves 71 are stacked in turn; the cleaning tea leaves 71 are designed in a leaf shape , and the surface of the cleaning tea leaves 71 is provided with scratches; when working, when the gas pushes the cleaning particles 7 to spray, the cleaning tea leaves 71 are pushed to be sprayed into the sewage, through the blade-shaped design of the cleaning tea leaves 71 and the scratches on the surface of the cleaning tea leaves 71 , during the spraying process of the clean tea leaves 71, they rotate and float in the water, so as to further purify the sewage.

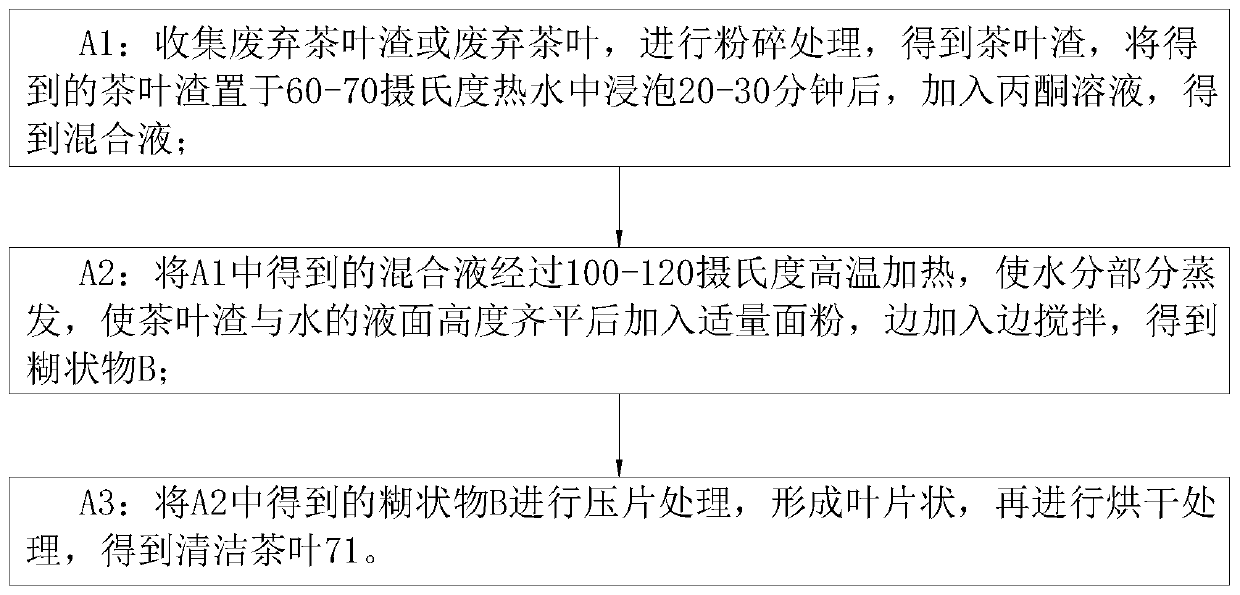

[0032] As an embodiment of the present invention, the preparation method of the clean tea leaves 71 includes the following steps:

[0033] A1: Collect waste tea leaves or waste tea leaves, crush them to obtain tea le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com