Preparation method of industrial cleaning agent

A cleaning agent and industrial technology, applied in the field of preparation of industrial cleaning agents, can solve the problems of inconspicuous effect, complex operation, single component, etc., and achieve the effect of remarkable effect, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

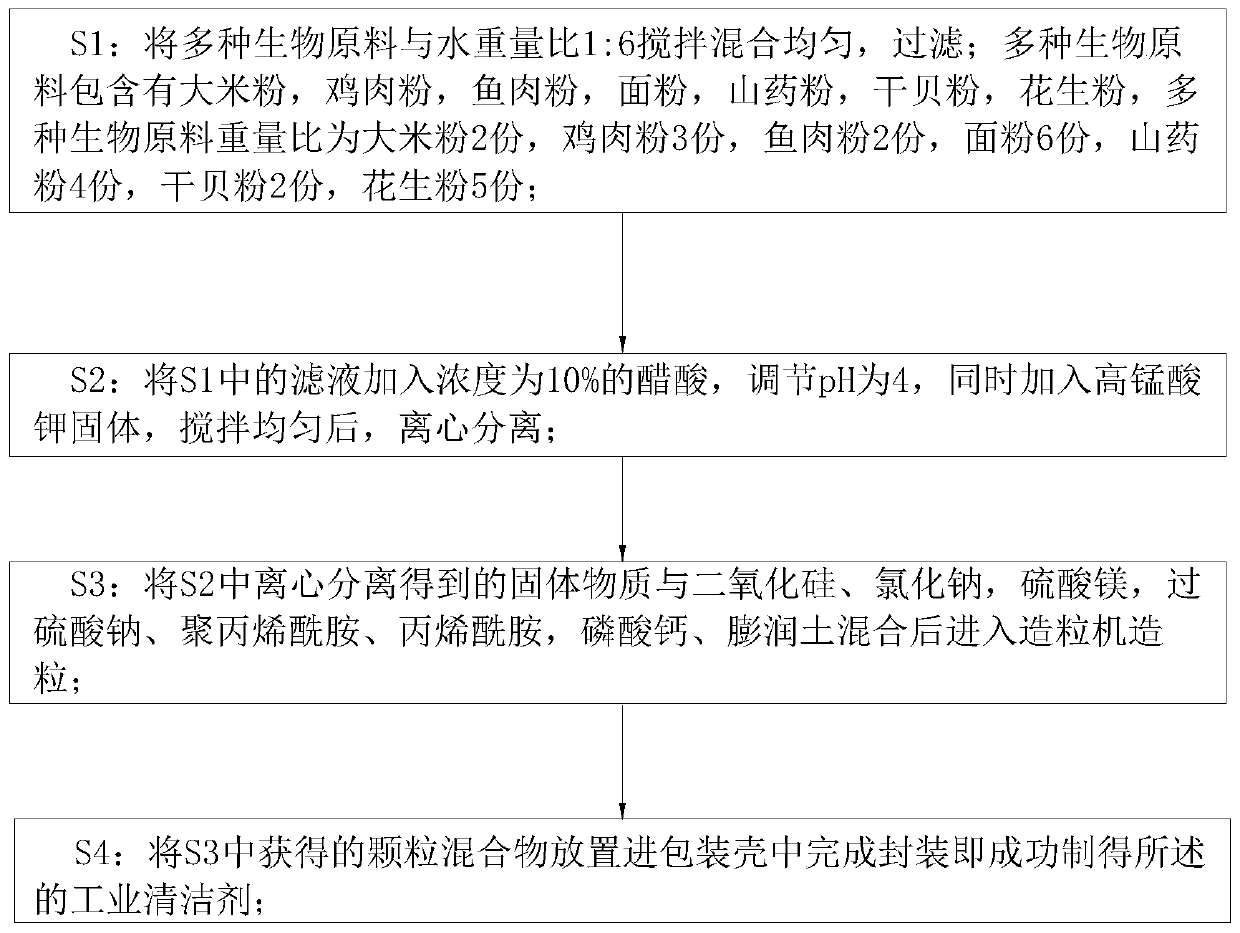

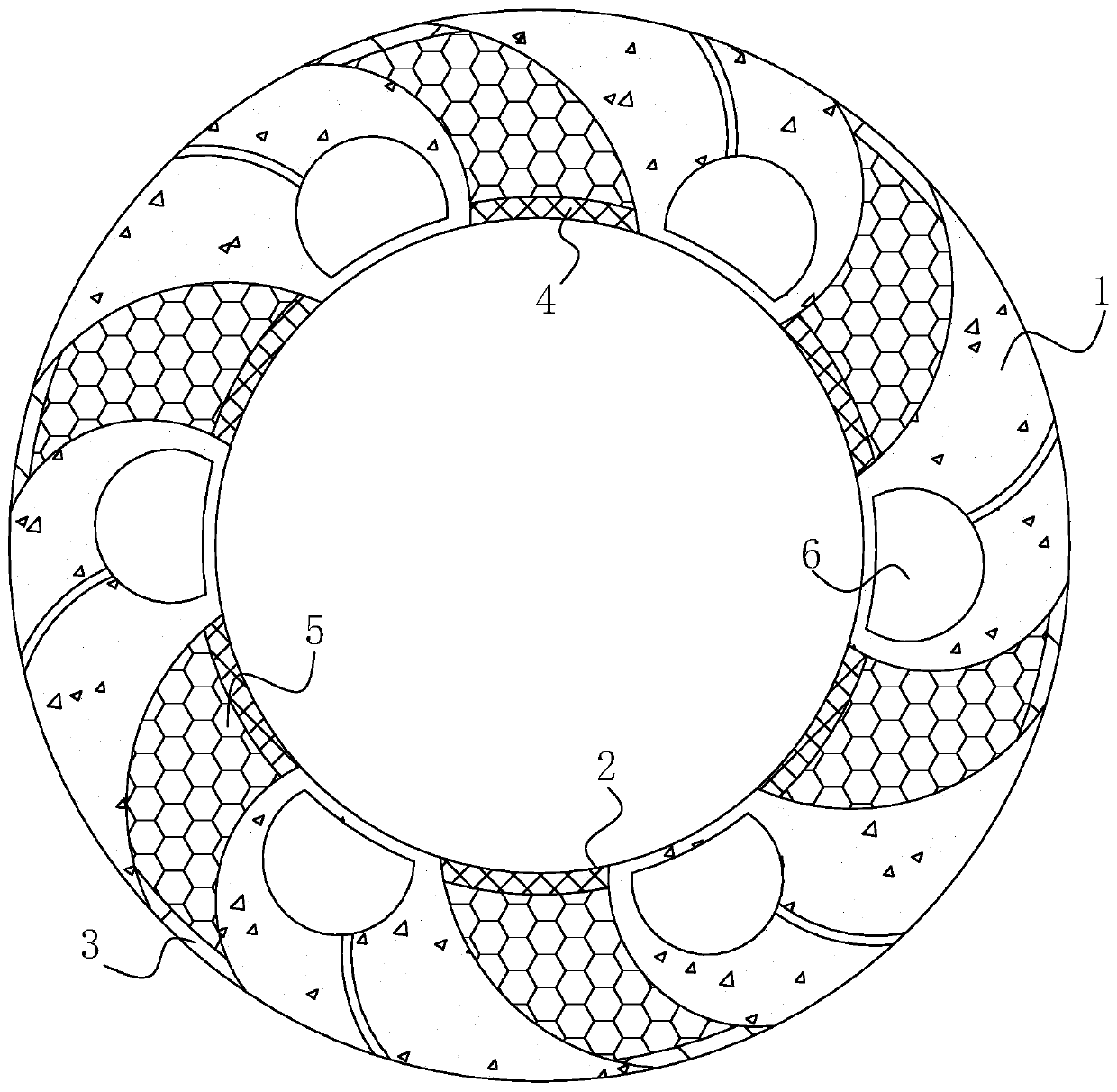

[0022] use Figure 1-Figure 2 The preparation method of an industrial cleaning agent according to an embodiment of the present invention is described as follows.

[0023] Such as Figure 1-Figure 2 Shown, the preparation method of a kind of industrial cleaning agent of the present invention, comprises the component of following parts by weight:

[0024] 100 parts of solid matter, 20 parts of silicon dioxide, 5 parts of sodium chloride, 5 parts of magnesium sulfate, 3 parts of sodium persulfate, 4 parts of polyacrylamide, 10 parts of acrylamide, 6 parts of calcium phosphate, 20 parts of bentonite.

[0025] The preparation method comprises the following steps:

[0026] S1: Stir and mix a variety of biological raw materials and water with a weight ratio of 1:6, and filter; a variety of biological raw materials include rice flour, chicken powder, fish meat powder, flour, yam powder, scallop powder, peanut powder, and various biological raw materials The weight ratio is 2 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com