Open type soft rock heading machine forepoling system and application method thereof

A technology of advanced support and roadheader, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of insufficient site conditions, easy occurrence of danger, and difficulty in applying large-scale construction equipment, and achieves the effect of simple structure and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

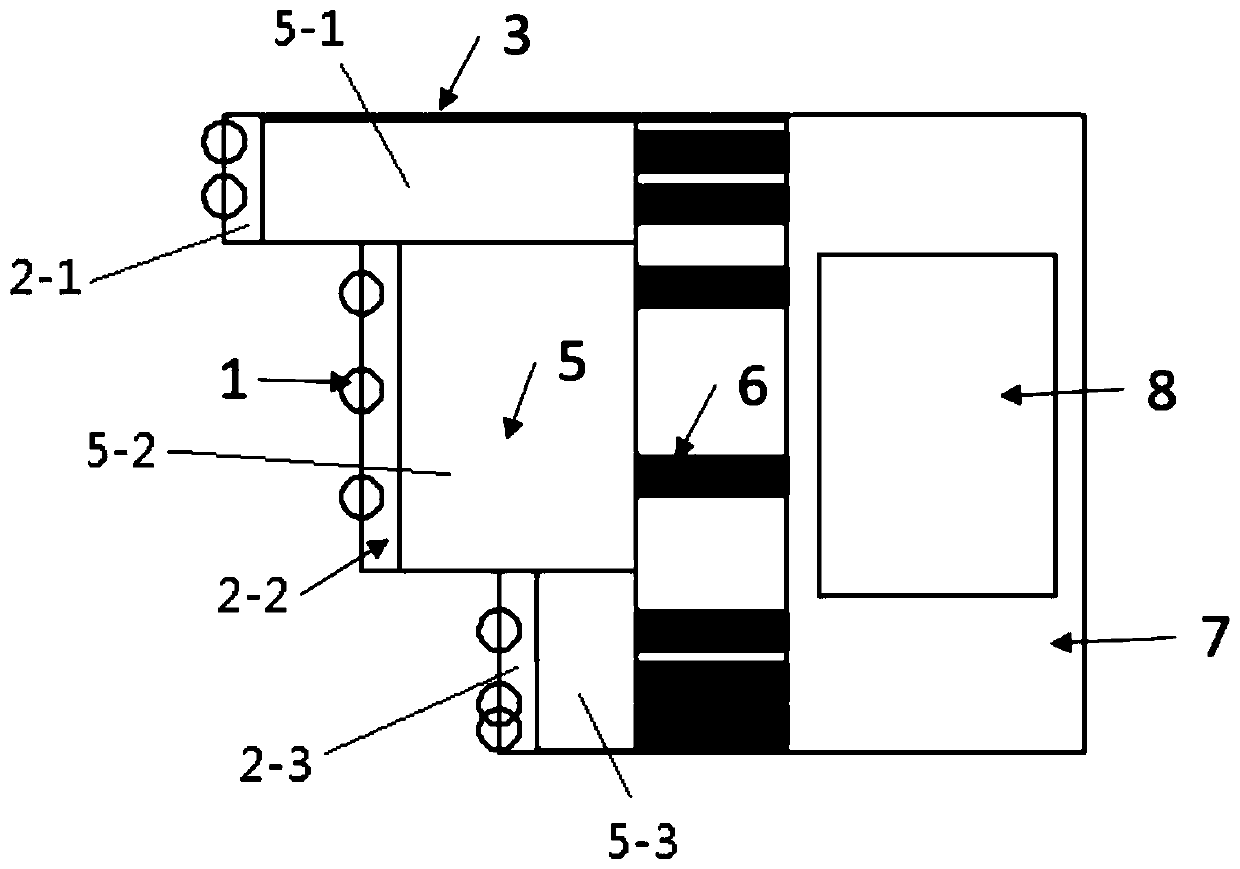

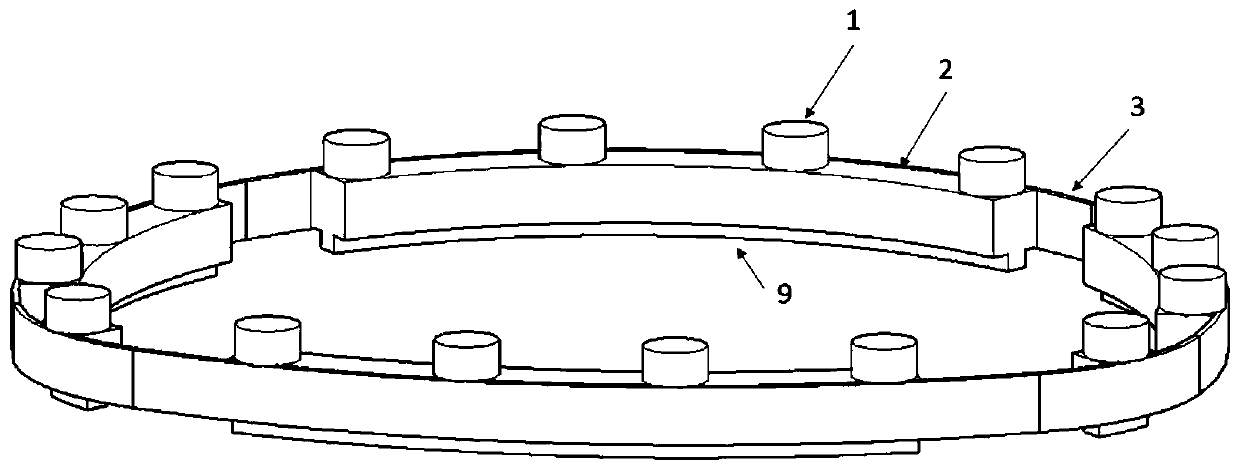

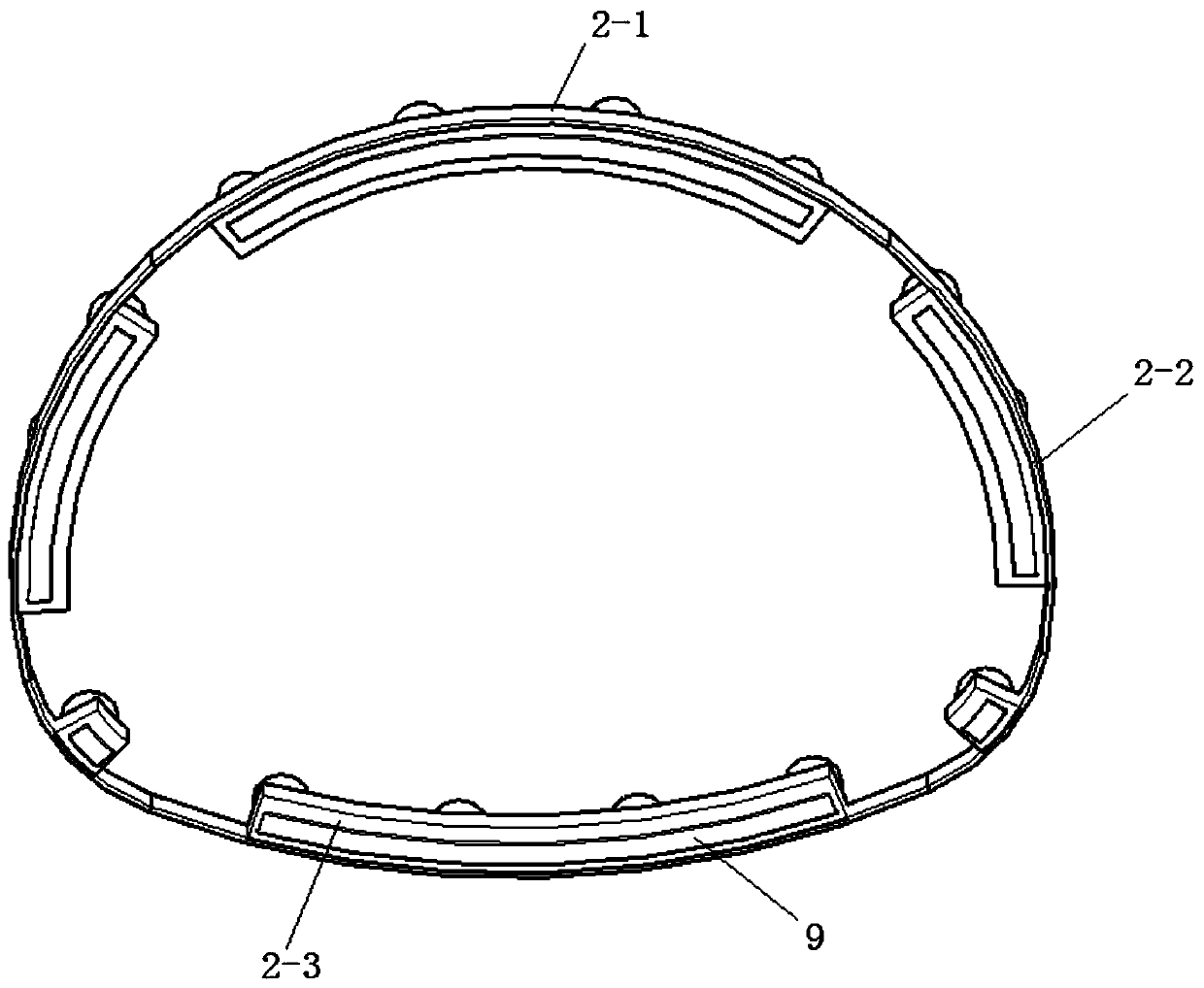

[0060] Such as Figure 1~4 or Figures 13 to 14 As shown, the advanced support system of the open type soft rock roadheader of the present invention includes a tool holder, a pushing part and an operating cabin 8, the tool holder includes a cutter head 2 and a cutter head connection 9, and the pushing part includes a circumferential power part 5 and oil cylinder 6; cutter head 2 and circumferential power part 5 are provided with a protective shell 3; the circumferential power part 5 is fixedly connected with the cutter head 2 through the cutter head joint 9, and the ring direction power part 5 is built-in for the cutter head 2. Provide the power source for the circumferential power; the oil cylinder 6 is arranged in a ring on the inner wall of the protective shell 3, one end of the oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com