A realization method of inversion and identification of crystal plastic material parameters based on nanoindentation experiment

A material parameter and nano-indentation technology, which is used in the application of stable tension/pressure to test material strength, analyze materials, and test material hardness, etc., can solve the problems of difficult material constitutive parameter identification, calculation result error, etc. The effect of high convergence, improved accuracy, high practical value and reference significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples.

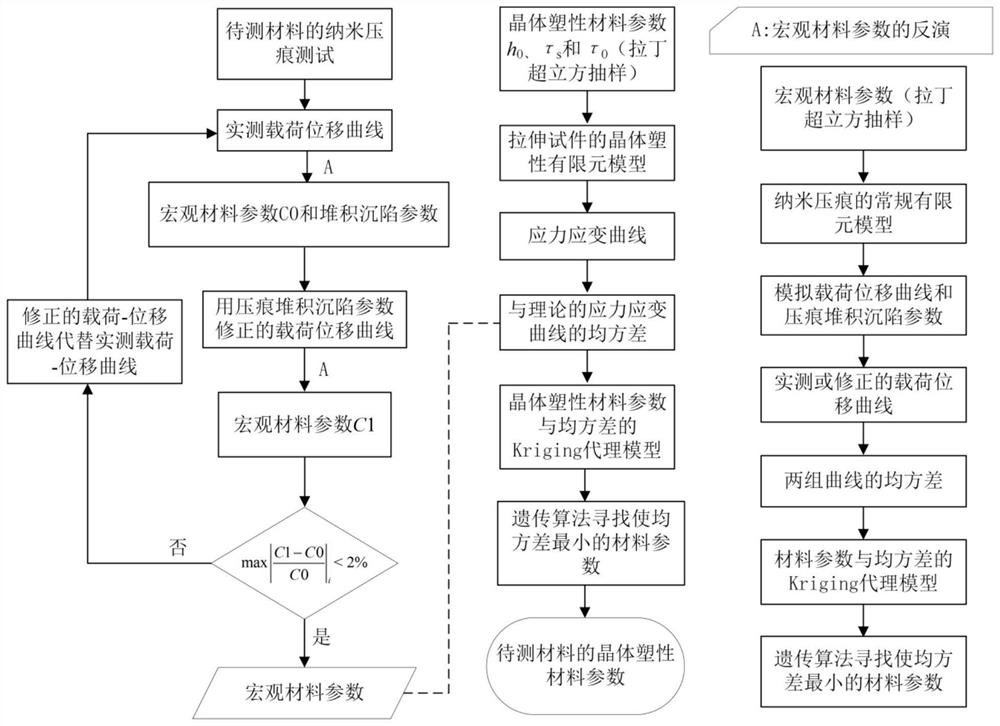

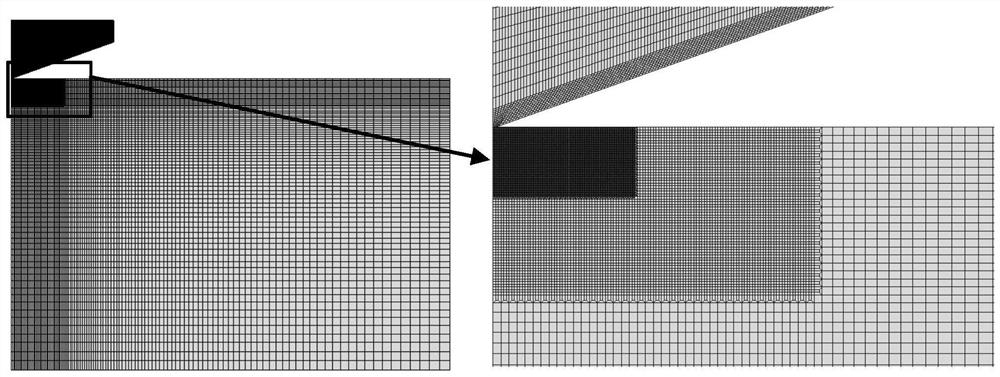

[0035] See attached figure 1 As shown, the specific implementation steps of the method for calibrating the microscopic constitutive parameters of metal materials based on nanoindentation and finite element simulation of crystal plastic material parameters include:

[0036] Step 1: Nanoindentation experiment of the metal material to be tested

[0037] 1-1: Select 304 stainless steel material as the test piece, cut the material, and use mechanical polishing and vibration polishing to obtain the nano-indentation test piece that meets the requirements;

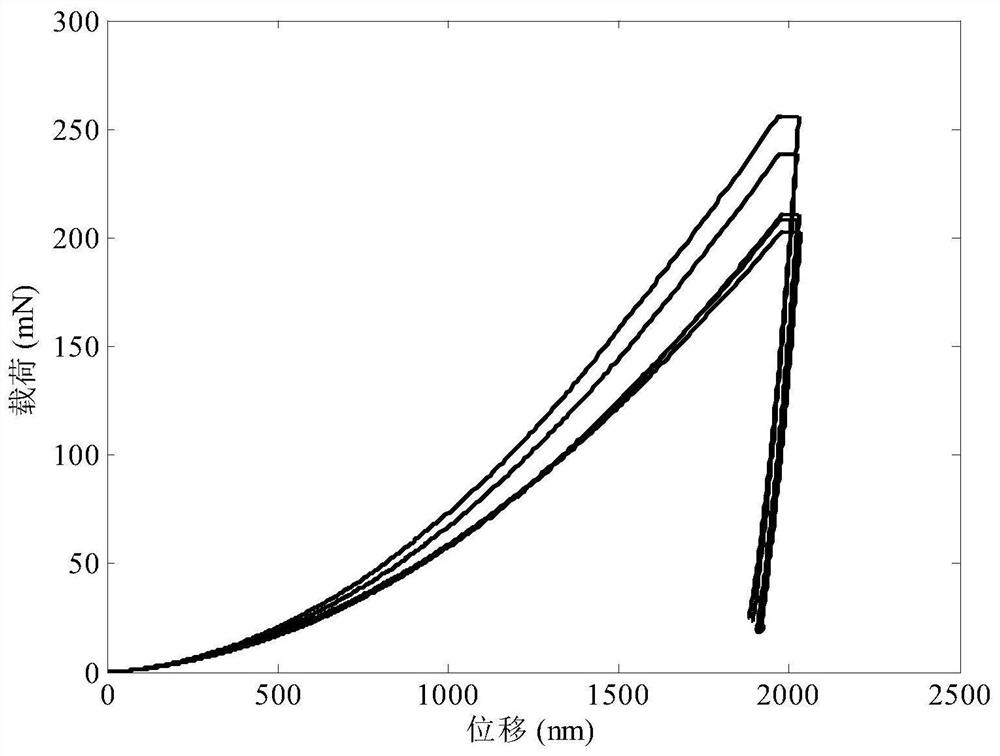

[0038] 1-2: Use the nano-indentation xp system to carry out indentation test on the indentation specimen. In the test, the indentation depth was set to 2 microns, and the experimental indentation response including load-displacement curve, maximum load, contact stiffness and contact hardness was obtained. Repeat the test many t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| strain hardening exponent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com