Method for treating radioactive waste water with kgm-rgo sponge

A technology of radioactive waste water and sponge, applied in radioactive purification, nuclear engineering, etc., can solve the problems that carbon materials are difficult to be widely used, carbon nanostructures are easy to aggregate, and the influence of volume change stress, etc., achieve rapid heat preservation, simple preparation process, The effect of efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of method utilizing KGM-rGO sponge to process radioactive waste water, comprises the following steps:

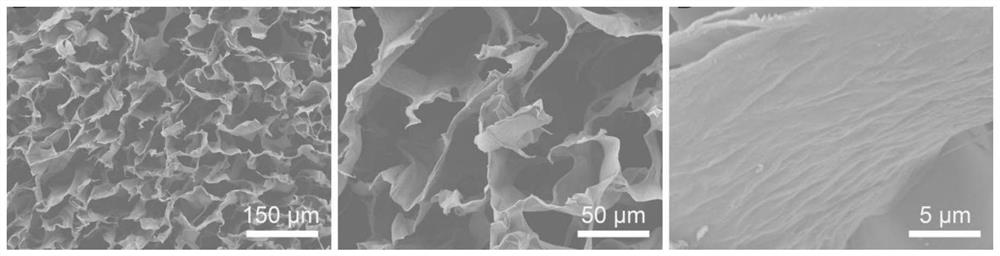

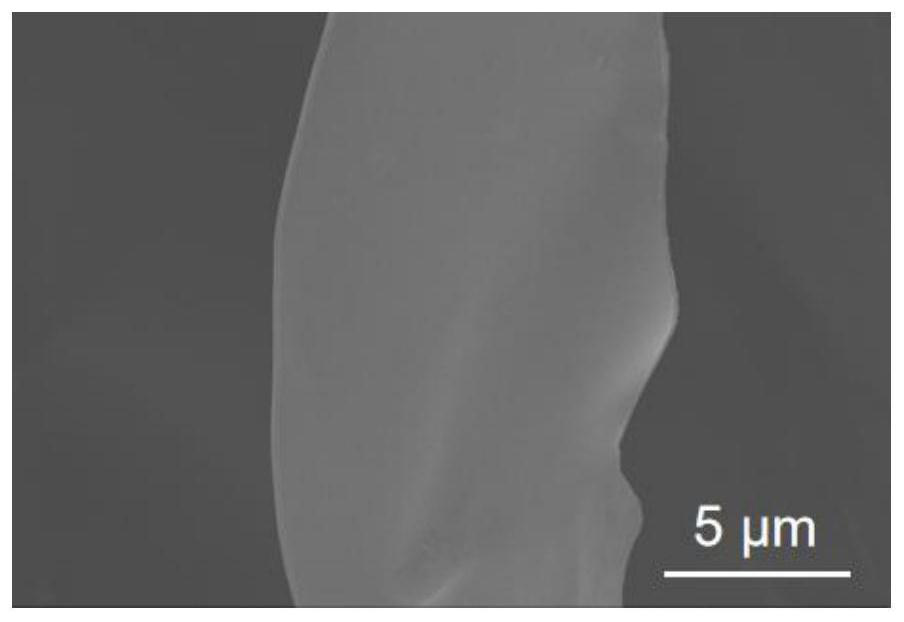

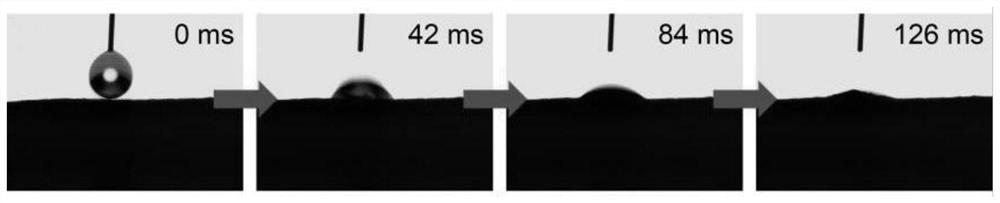

[0045] Step 1. Disperse 0.1g of graphene oxide in 100mL of deionized water, ultrasonicate for 4 hours to obtain a graphene oxide solution; then add 1g of konjac glucomannan to the graphene oxide solution, mix and stir at room temperature for 24 hours, and freeze into blocks After that, vacuum freeze-drying; put the dried solid sample into the reaction kettle, add 100mL 0.3mol / L KOH solution and 100mL absolute ethanol at the same time, put the reaction kettle in an oven and keep it warm at 80°C for 8h to realize deacetylation and oxidation Reduction of graphene; vacuum freeze-drying after taking out to obtain konjac glucomannan-reduced graphene oxide sponge (KGS); the power of ultrasonic is 300W, and the ultrasonic frequency is 35kHz; the temperature of vacuum freeze-drying is -50 ℃; Degree 1.8 Pa; figure 1 The SEM figure of the konjac glucomannan-reduced graph...

Embodiment 2

[0055] A kind of method utilizing KGM-rGO sponge to process radioactive waste water, comprises the following steps:

[0056]Step 1. Disperse 0.2g of graphene oxide in 200mL of deionized water and ultrasonicate for 5 hours to obtain a graphene oxide solution; then add 2g of konjac glucomannan to the graphene oxide solution, mix and stir at room temperature for 24 hours, and freeze into blocks Afterwards, vacuum freeze-drying; put the dried solid sample into the reaction kettle, add 200mL 0.4mol / L KOH solution and 200mL absolute ethanol at the same time, put the reaction kettle in an oven at 80°C for 10h to realize deacetylation and oxidation Reduction of graphene; vacuum freeze-drying after taking out to obtain konjac glucomannan-reduced graphene oxide sponge (KGS); the power of ultrasonic is 300W, and the ultrasonic frequency is 35kHz; the temperature of vacuum freeze-drying is -50 ℃; Degree 1.8 Pa;

[0057] Step 2, set up a holding tank on the upper surface of the polystyren...

Embodiment 3

[0059] A kind of method utilizing KGM-rGO sponge to process radioactive waste water, comprises the following steps:

[0060] Step 1. Disperse 0.1g of modified graphene oxide in 100mL of deionized water, and ultrasonicate for 4 hours to obtain a graphene oxide solution; then add 1g of konjac glucomannan to the graphene oxide solution, mix and stir at room temperature for 24 hours, and freeze After forming a block, vacuum freeze-dry; put the dried solid sample into the reaction kettle, add 100mL 0.3mol / L KOH solution and 100mL absolute ethanol at the same time, put the reaction kettle in an oven at 80°C for 8h to realize deacetylation and reduction of modified graphene oxide; vacuum freeze-drying after taking out to obtain konjac glucomannan-reduced graphene oxide sponge; ultrasonic power is 300W, ultrasonic frequency is 35kHz; vacuum freeze-drying temperature is -50°C; The vacuum degree is 1.8 Pa; the preparation method of the modified graphene oxide is: adding 1 g of graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com