Method for weakening electromagnetic vibration of electric vehicle permanent magnet drive motor

A permanent magnet drive, electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problem of increasing torque ripple of permanent magnet motor, weakening torque ripple, weakening cogging torque and tooth harmonics of permanent magnet motor Problems such as wave electromotive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

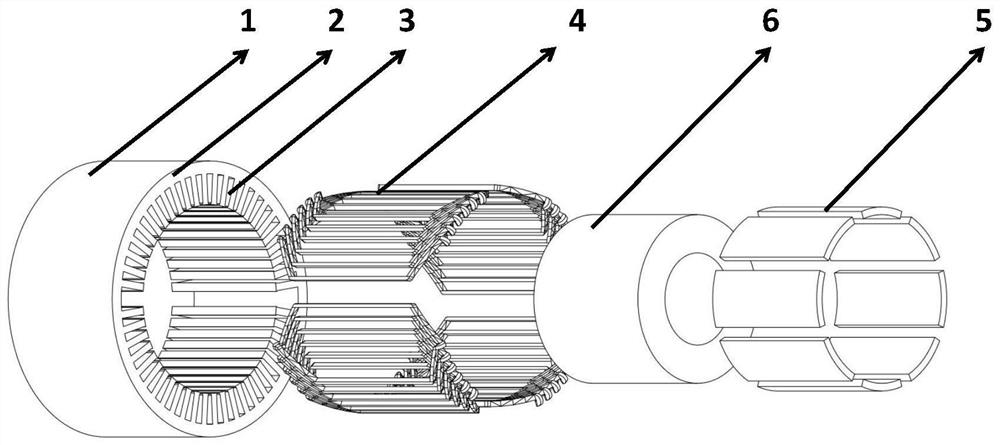

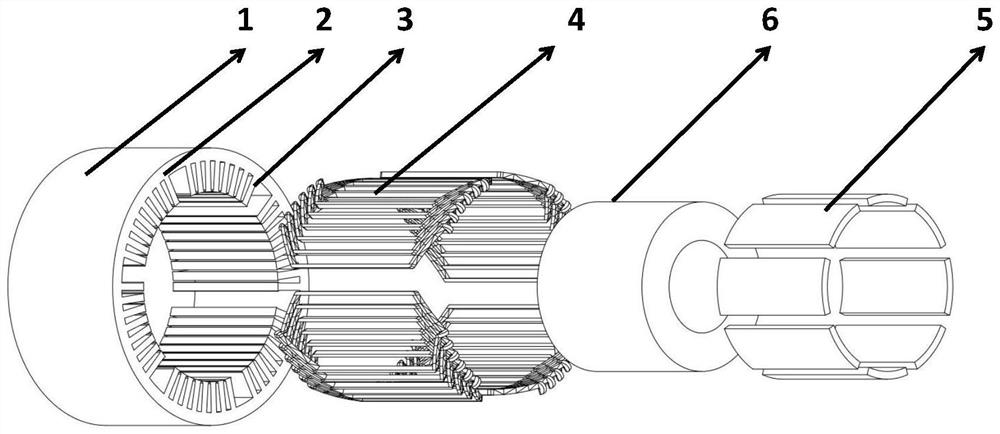

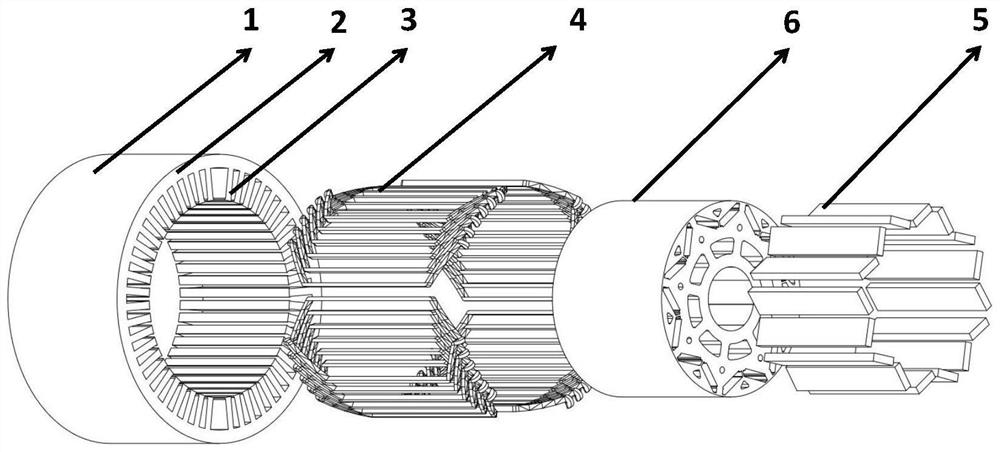

[0050] This embodiment relates to a method for weakening electromagnetic vibration of a permanent magnet drive motor of an electric vehicle, in particular to a method for weakening electromagnetic vibration of a permanent magnet synchronous motor combined with unequal slot widths. The motor includes a stator, a permanent magnet rotor, and an armature winding. The structure of the stator is different from that of conventional permanent magnet synchronous motor stators. The new stator has a combined structure with unequal slot widths. The width of all the teeth on the stator is the same. The sum of the widths of all the slots of the stator is kept constant, and the total slot area of all the slots of the stator is kept constant. By changing one of the slots of the stator or The width of multiple slots, making it different from other slot widths.

[0051] Through this combination of unequal slot widths, the cogging torque, tooth harmonic electromotive force and torque ripple o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com