Vertical steaming mill

A technology of steaming and refining, which is applied in the direction of mixing/kneading with vertical installation tools, dough mixers, structural components of mixing/kneading machines, etc., which can solve the time-consuming and laborious process of material removal and the emulsification effect of the steamer Poor and other problems, to achieve the effect of improving taste, better taste and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

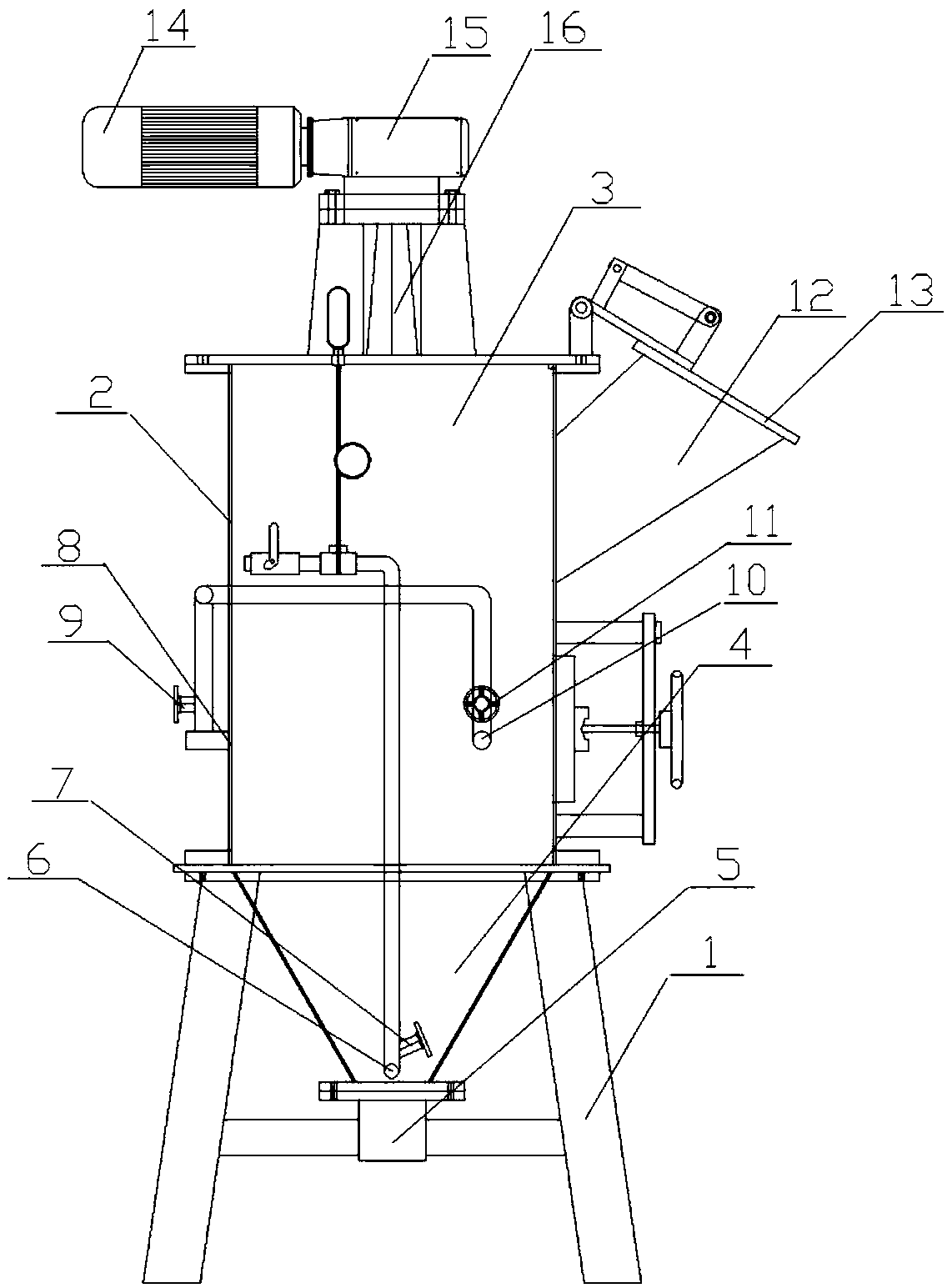

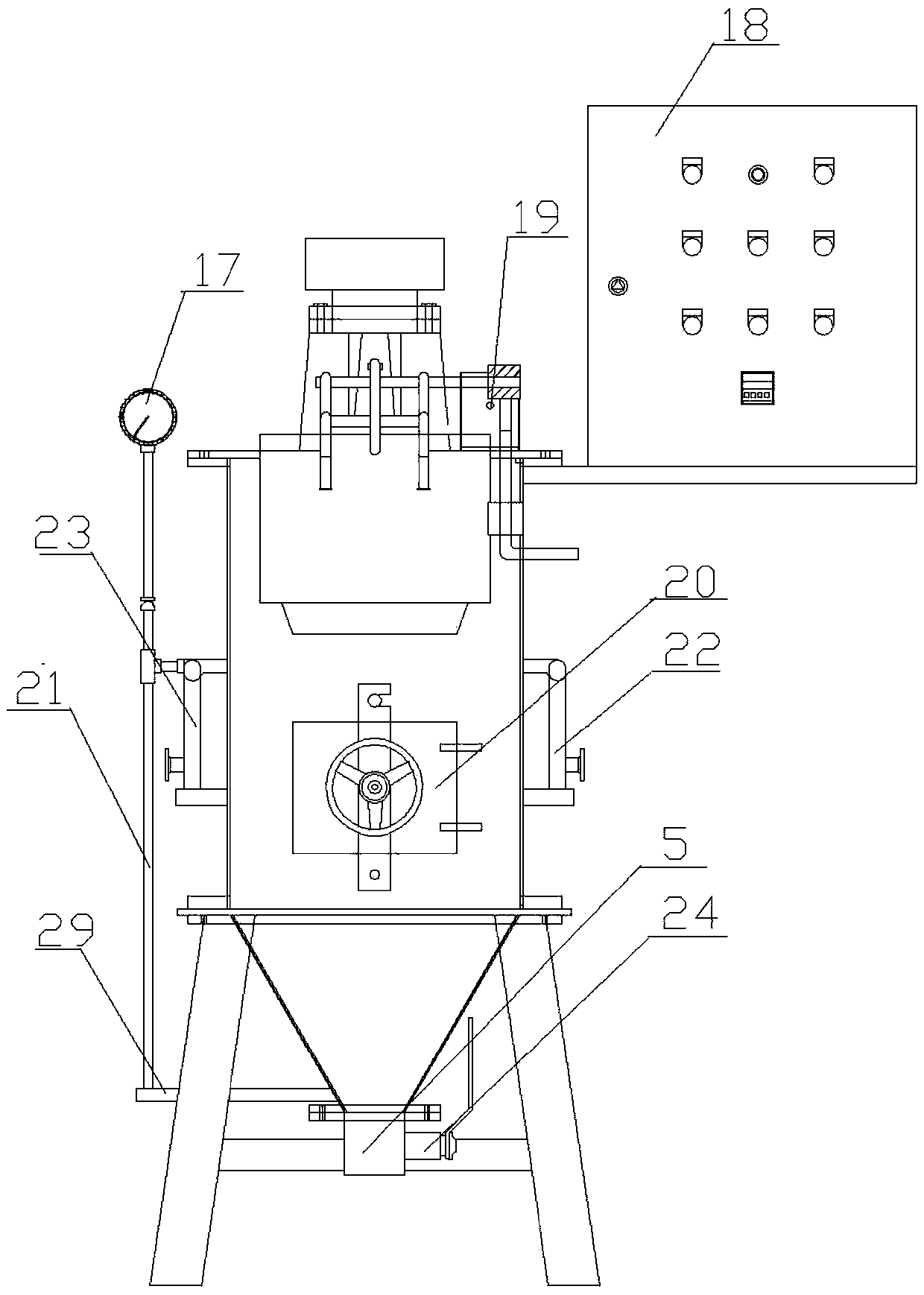

[0025] Such as figure 1 and figure 2 Shown, a kind of vertical steaming machine, comprises frame 1, steaming bucket 2, drive motor 14, electric control box 18 steam inlet pipe 21 and stirring mechanism 16, steaming bucket 2 is arranged on the frame 1, steaming The refining barrel 2 is connected to the feed hopper 12, and the feeding hopper 12 and the steaming refining barrel 2 are arranged obliquely, and the upper end of the feeding hopper 12 is provided with a sealed upper cover 13. The steaming barrel 2 includes a cylindrical barrel body 3 and an inverted conical barrel body 4, the cylindrical barrel body 3 is arranged on the upper end of the inverted conical barrel body 4, and the cylindrical barrel body 3 and the inverted conical barrel body 4 are designed in one piece . The steaming barrel 2 is provided with an equipment inspection port 20 .

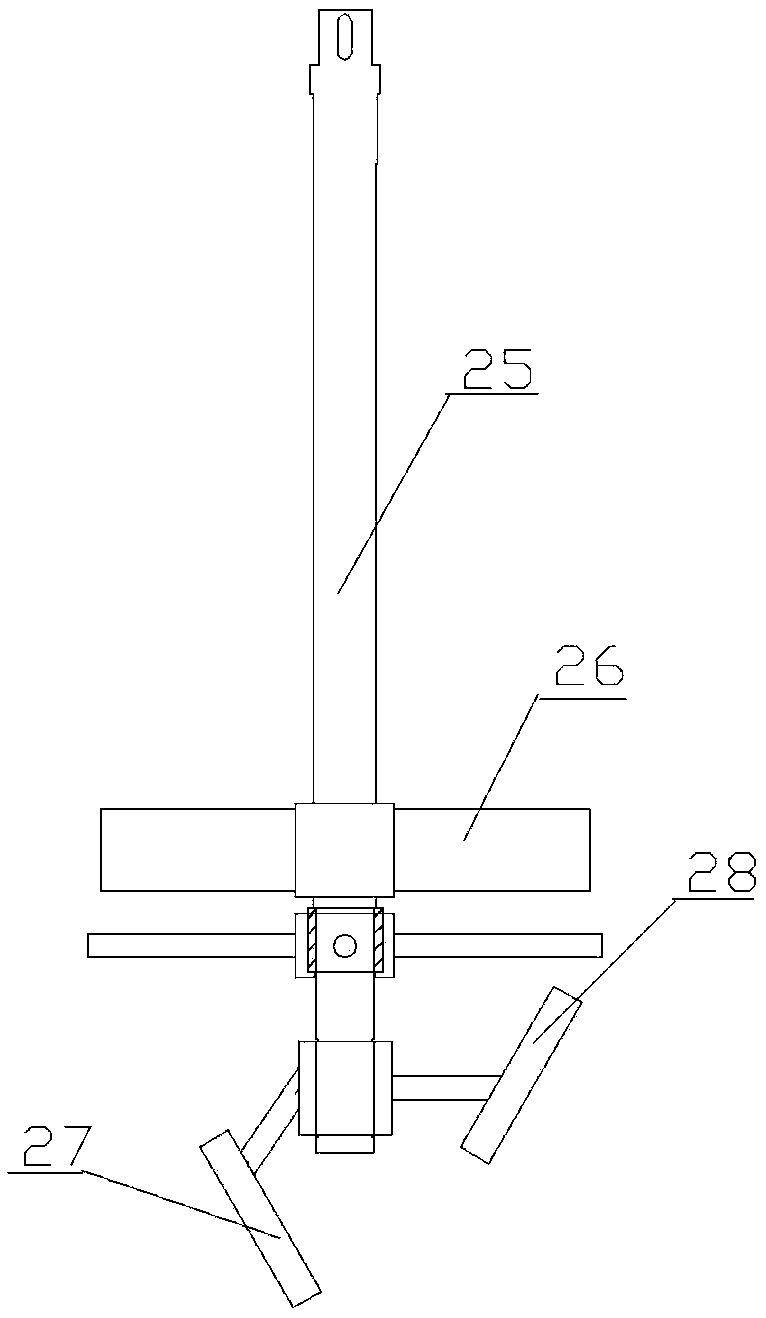

[0026] One end of the stirring mechanism 16 extends into the bottom of the steaming barrel 2 , the other end extends out of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com