Thermal cycle energy-saving injection molding machine

An injection molding machine and thermal cycle technology, applied in the field of polymer material molding machinery, can solve problems such as energy consumption, achieve the effect of improving heating efficiency and realizing energy cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

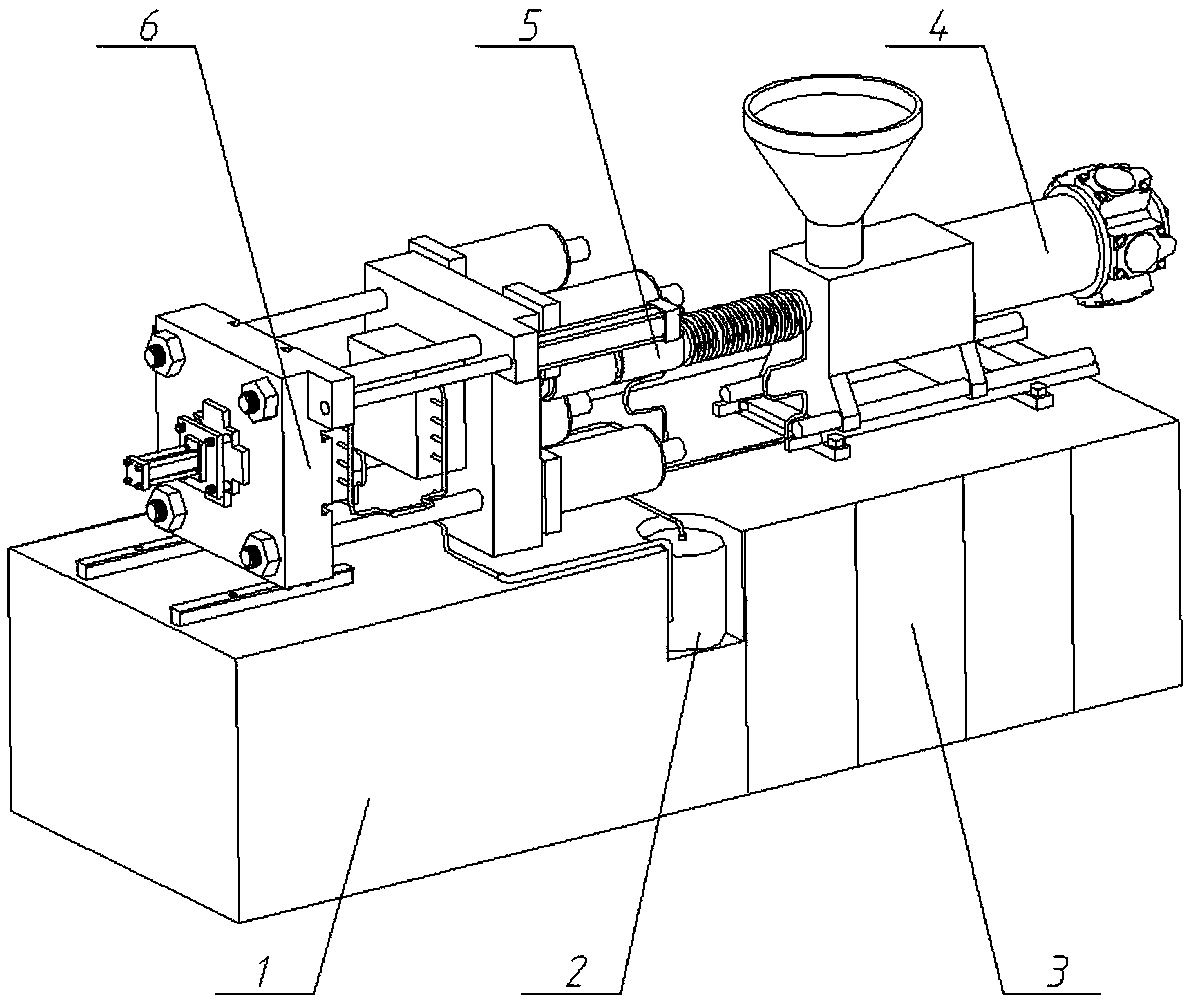

[0024] The object of the present invention is to provide a thermal cycle energy-saving injection molding machine such as figure 1 As shown, it is mainly composed of frame 1, thermal cycle system 2, control system 3, injection system 4, plasticizing system 5, mold clamping system 6 and so on. Except for the thermal cycle system 2, other devices are the same as the traditional injection molding machine.

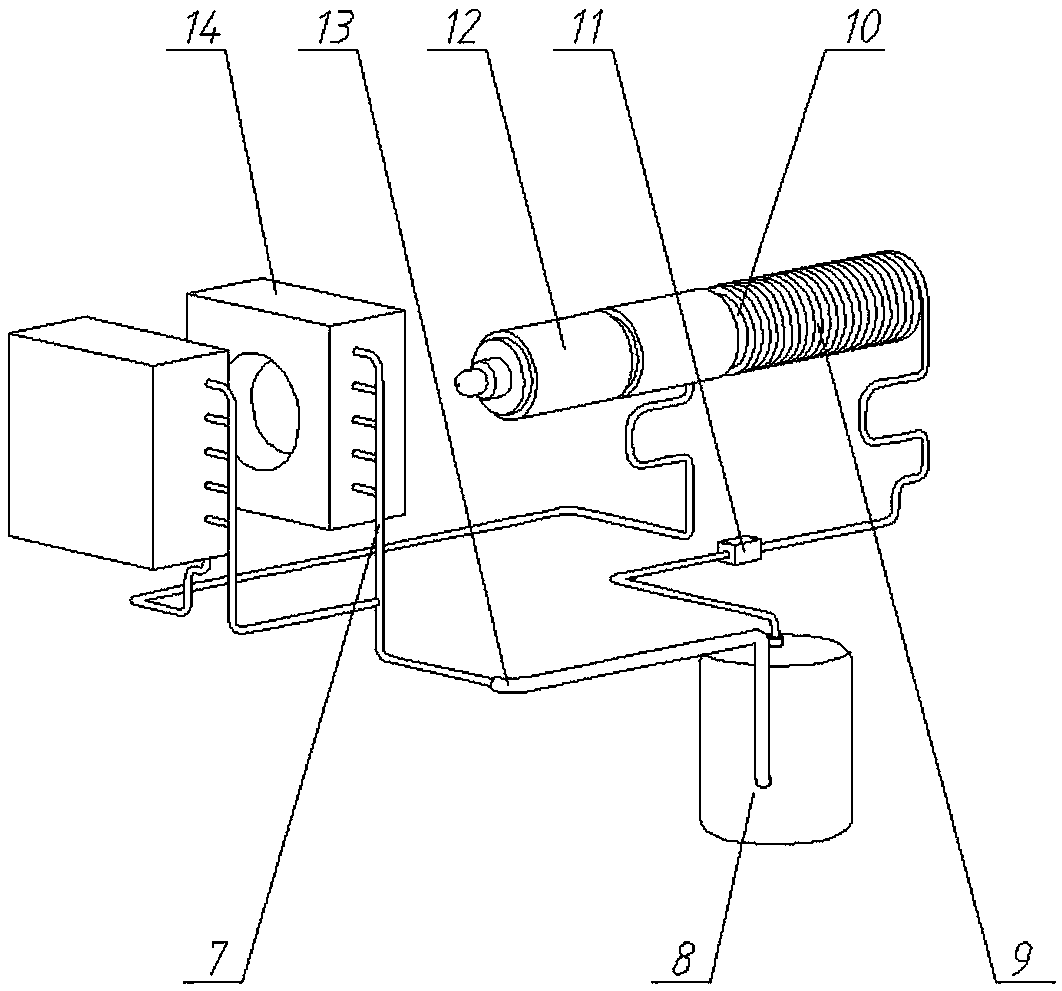

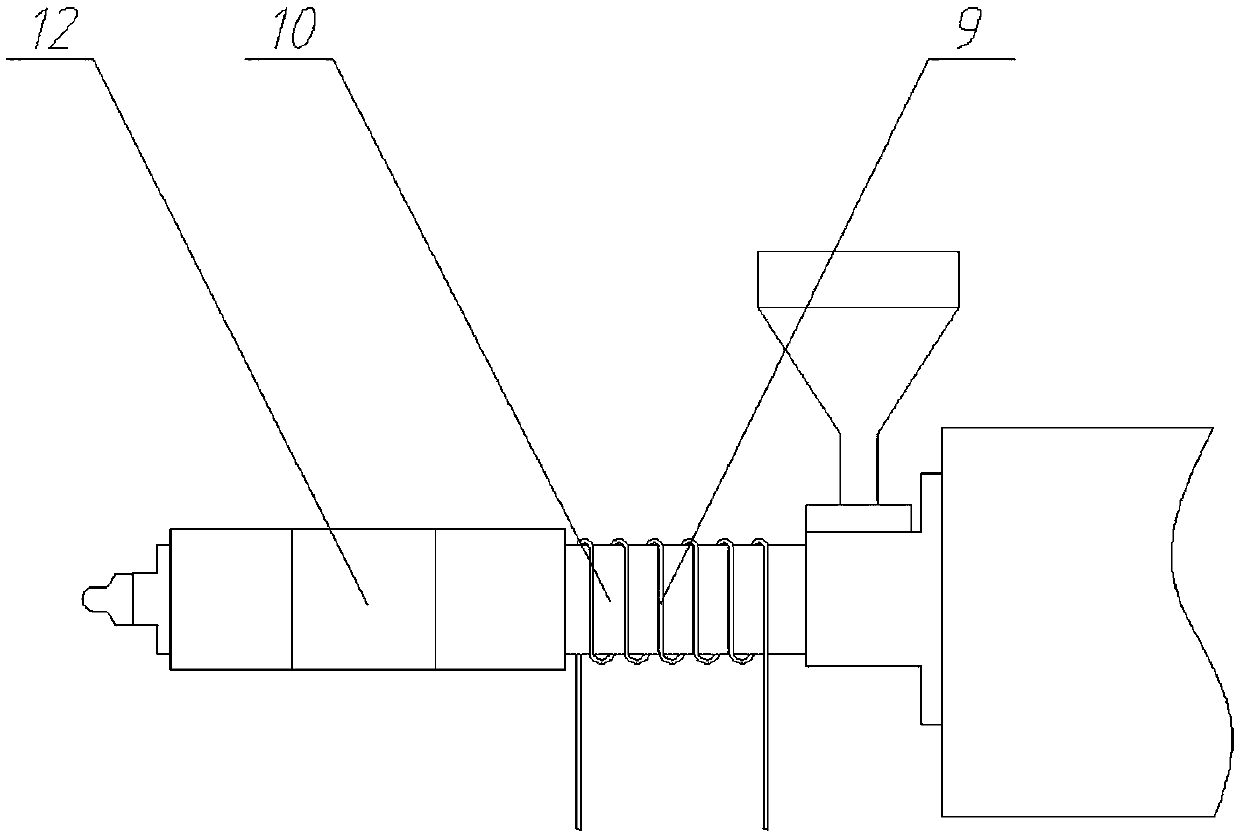

[0025] The thermal cycle system 2 is mainly composed of an evaporator 7, a compressor 8, a condenser 9, a barrel 10, an expansion valve 11, a heating coil 12, a connecting pipe 13, and a refrigerant, etc., such as figure 2 shown. The evaporator 7 is arranged in the mold 14, the compressor 8 is arranged at the lower body between the front template of the injection molding machine and the injection seat, and the condenser 9 is arranged on the cylinder 10, as image 3 As shown, the expansion valve 11 is arranged between the compressor 8 and the condenser 9, and the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com