Fiber woven fabric and prepreg thereof

A technology of fiber weaving and prepreg, which is applied in the field of fiber materials, can solve problems such as delamination and poor bonding, and achieve the effects of increasing resin impregnation rate, reducing specific gravity, and preventing delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose, technical effect and technical means of the present invention, the detailed description is as follows in conjunction with the accompanying drawings.

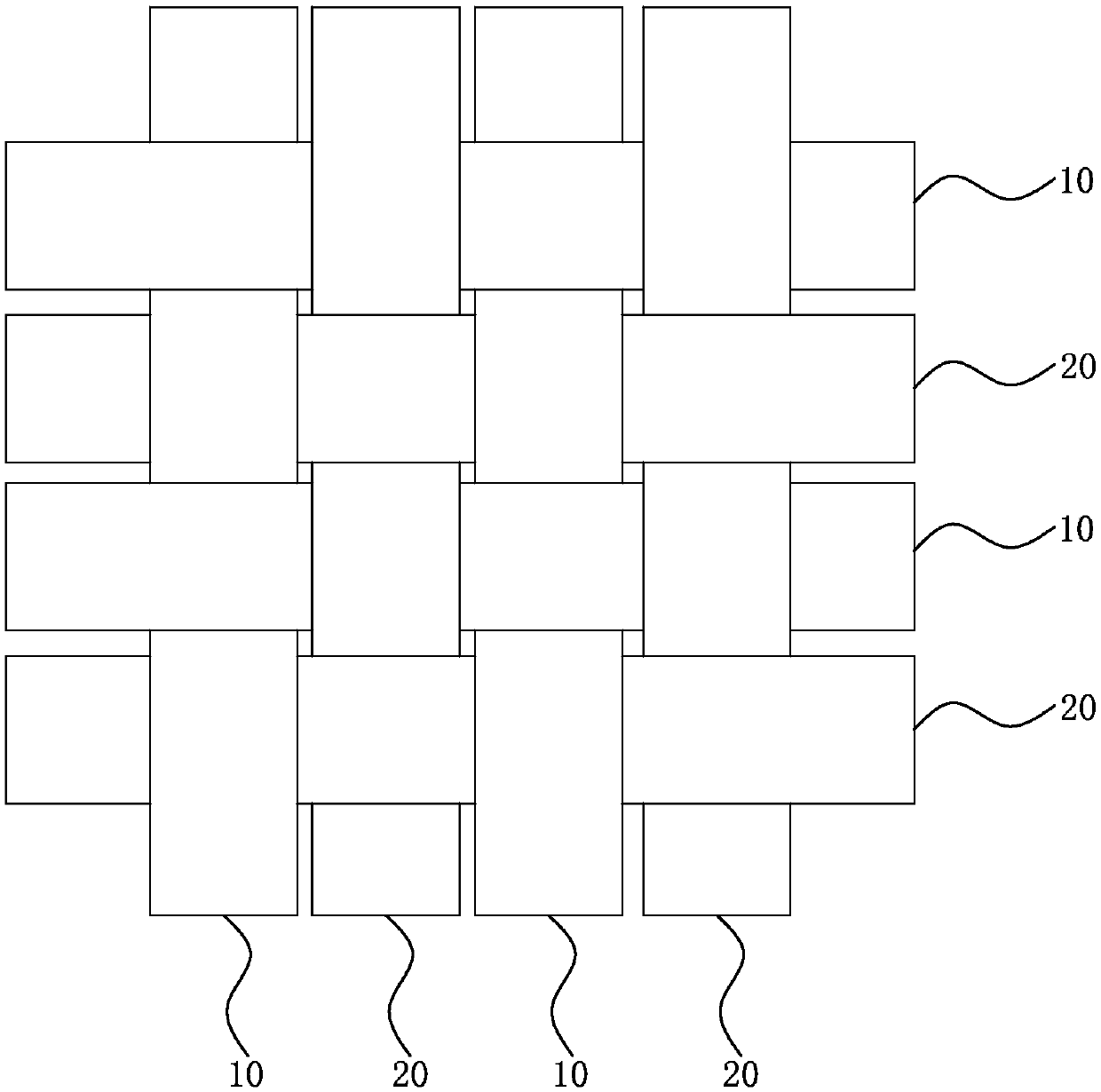

[0023] see figure 1 and figure 2 shown, where figure 1 Illustrated as a schematic diagram of fiber yarn bundles and resin strips in the fiber woven cloth of the present invention, figure 2 It is a schematic structural view of the fiber woven fabric of the present invention.

[0024] In this embodiment, the fiber woven cloth of the present invention includes several diameter yarns and several weft yarns, and the diameter yarns and weft yarns are alternately interwoven one above the other, so the warp and weft points appear alternately at a ratio of 1:1, and the fiber The woven cloth is a plain weave, wherein the diameter yarns and weft yarns are fiber yarn bundles 10 and resin strands 20 interlaced, that is, the fiber yarn bundles 10 and resin strands 20 are arr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap