A kind of road and bridge steel formwork stripping device

A technology for steel formwork and mold removal, which is used in bridges, bridge construction, and mold shell processing. , the effect of reducing risk and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

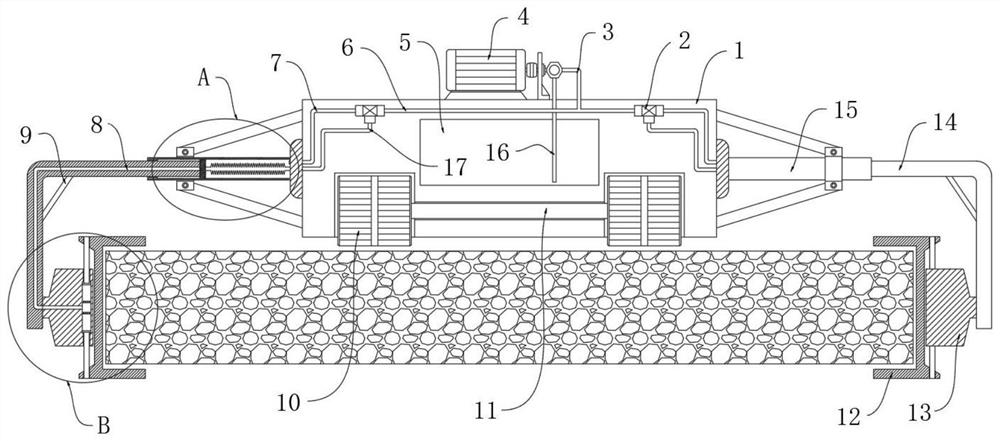

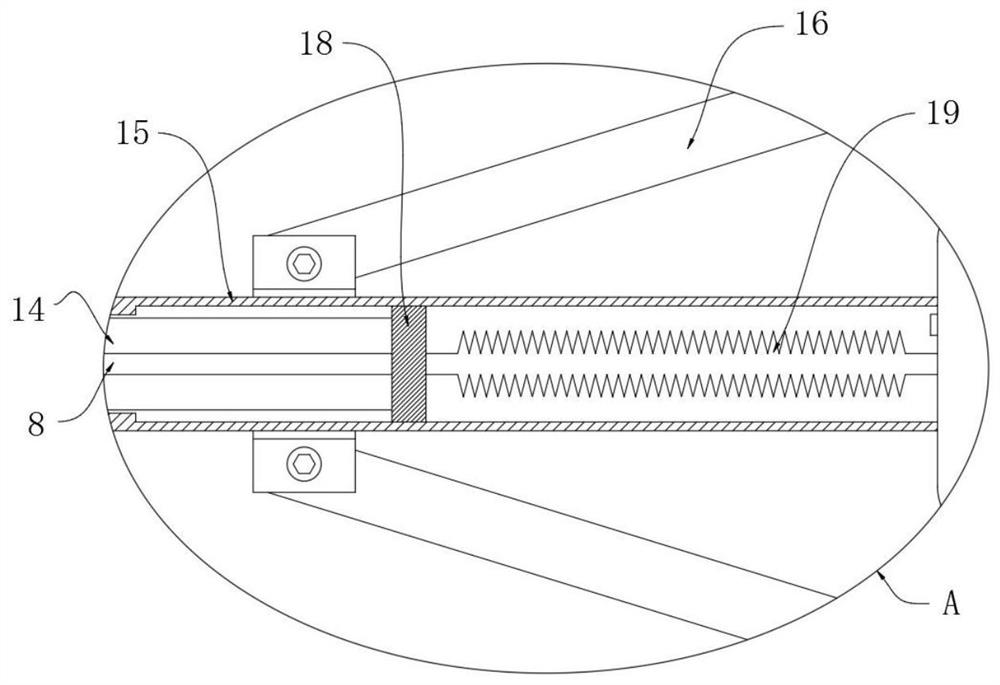

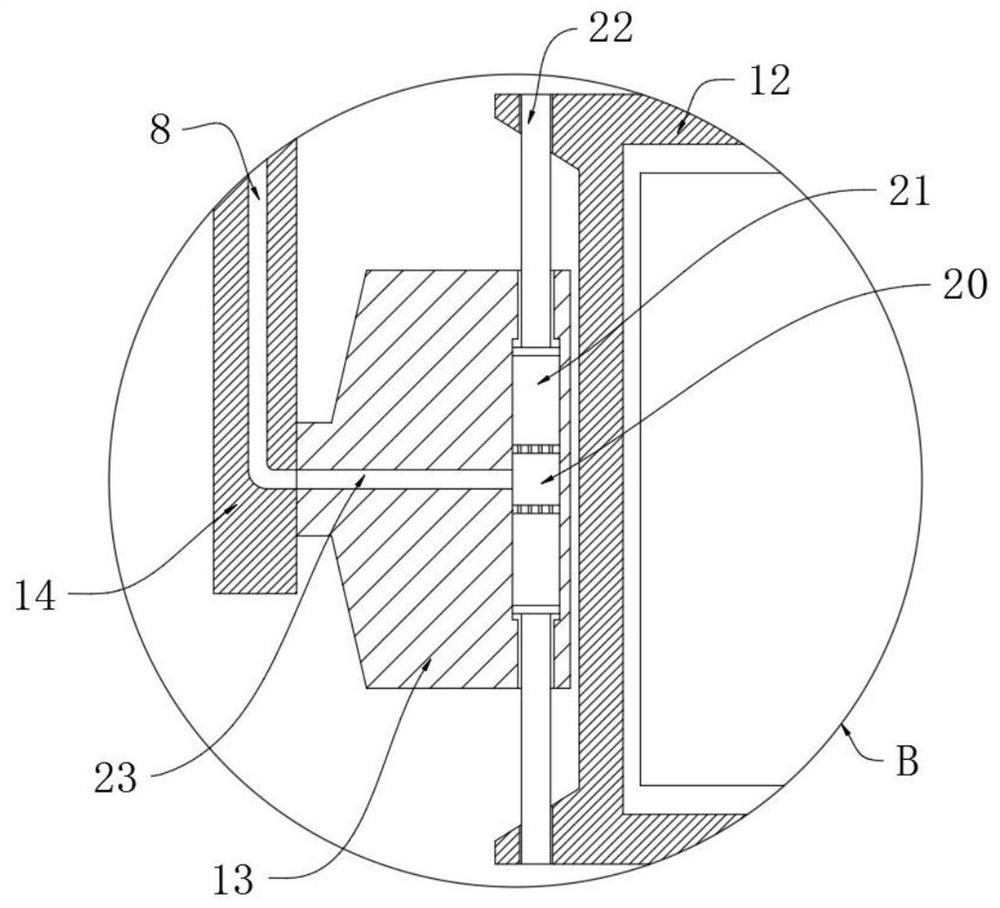

[0032] refer to Figure 1-4 , a road and bridge steel formwork ejection device, including a body 1 placed on the bridge body, two hydraulic cylinders 15 are symmetrically fixed and fixed on both sides of the body 1, each hydraulic cylinder 15 is sealed and inserted with a right-angle rod 14, The lower end of each right angle bar 14 is equipped with a mold ejector 13, and a hydraulic control system is installed on the body 1. The hydraulic control system includes a hydraulic pump 4 fixedly installed on the upper surface of the body 1. The oil suction pipe 16 and the oil pressure pipe 3 are respectively installed on the hydraulic pump 4. The oil tank 5 is embedded in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com