Double-high-pressure jet grouting stirring drill bit and construction method thereof

A dual-high-pressure, high-pressure injection technology, applied in the direction of basic structure engineering, construction, sheet pile walls, etc., can solve the problems of high engineering cost, slow pile forming speed, poor cutting ability of soil, etc., to improve the economic benefits of enterprises, rotate The effect of high spray mixing efficiency and reduced engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

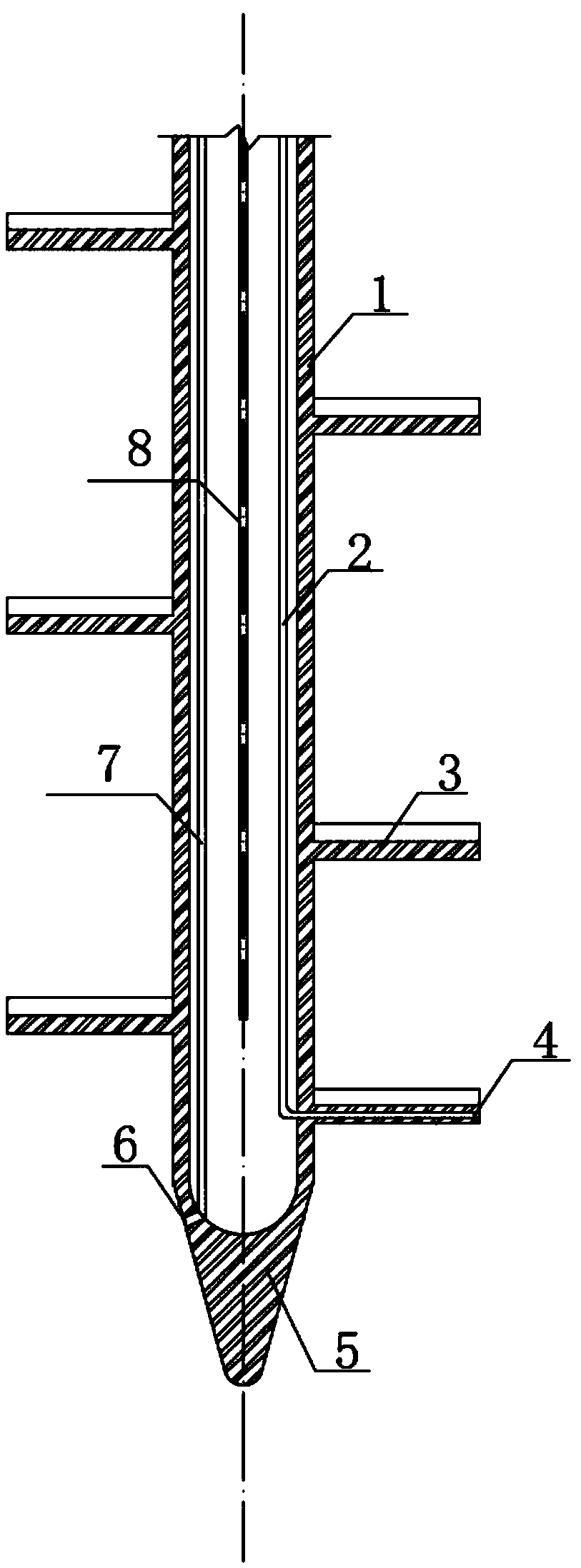

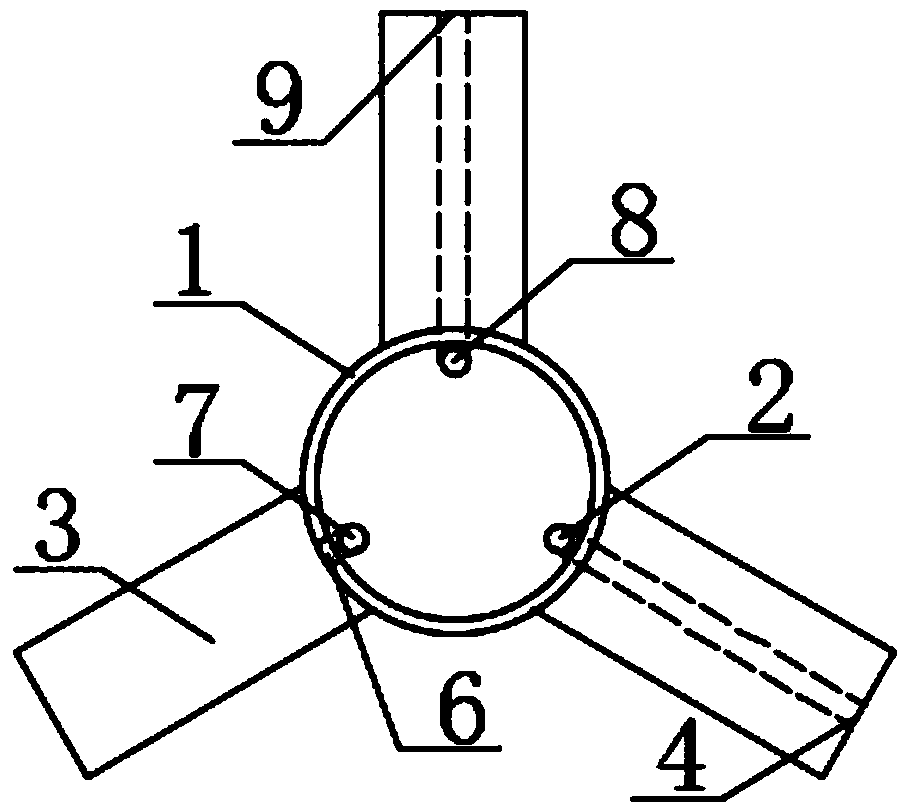

[0013] See attached Figure 1 ~ Figure 2 , the present invention consists of a drill bit 5 and a drill pipe 1 provided with a high-pressure grouting pipe 2, a high-pressure water injection pipe 8, a stirring blade 3 and a normal-pressure grouting pipe 7. 7 The high-pressure grouting pipe 2 and the high-pressure water injection pipe 8 arranged in the shape of a character, the high-pressure grouting port 4 of the high-pressure grouting pipe 2 and the high-pressure water injection port 9 of the high-pressure water injection pipe 8 are arranged on the mixing blade 3 near the drill bit 5 down, and the high-pressure water jet 9 is above the high-pressure grouting port 4; the normal-pressure spout 6 of the normal-pressure grouting pipe 7 is arranged at the joint of the drill bit 5 and the drill pipe 1, and is connected with the high-pressure grouting port 3 and The high-pressure water jets 9 carry out rotary spraying and stirring to the soil together.

[0014] The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com