A reciprocating plunger pump

A plunger pump, reciprocating technology, applied in the field of reciprocating plunger pumps, can solve the problem of not being able to actively and conveniently adjust the volume of the working chamber, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

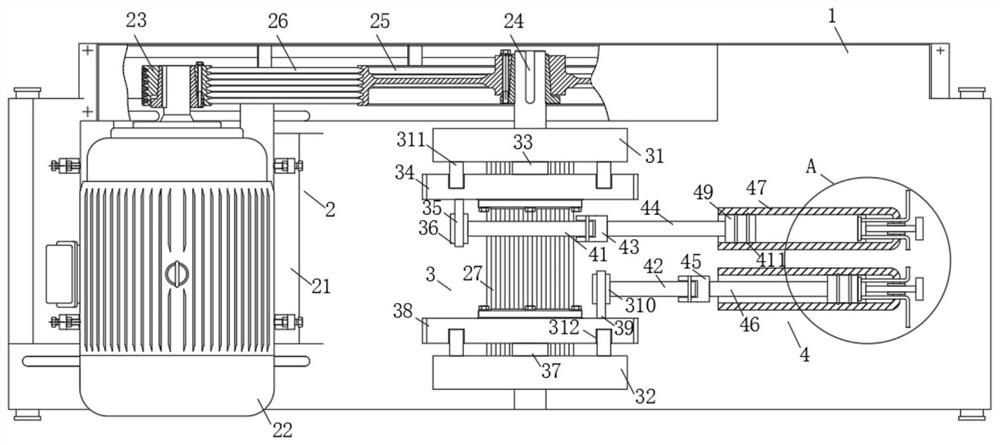

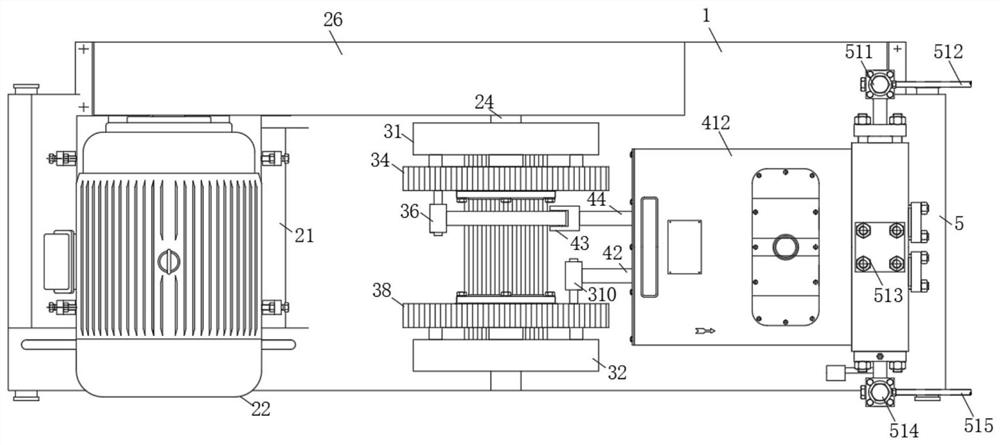

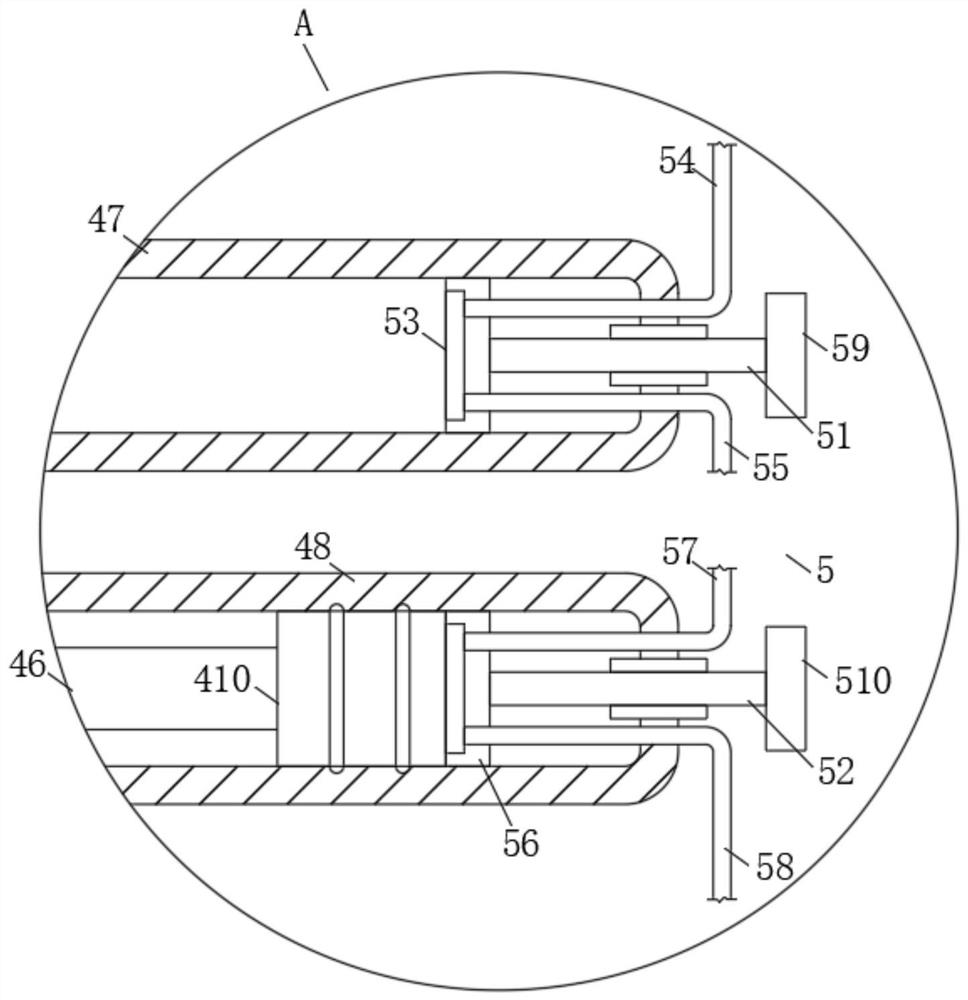

[0019] refer to Figure 1-5, a reciprocating plunger pump, comprising a base 1, a power source mechanism 2, a reciprocating drive mechanism 3 and a piston mechanism 4, the power source mechanism 2, the reciprocating drive mechanism 3 and the piston mechanism 4 are all arranged on the top of the base 1 , and the power source mechanism 2 and the piston mechanism 4 are respectively arranged on both sides of the reciprocating drive mechanism 3. The power source mechanism 2 includes a fixed frame 21, a servo motor 22, a first transmission wheel 23, a rotating shaft 24, a second The transmission wheel 25, the transmission belt 26 and the transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com