Neptunium dioxide-plutonium dioxide dissolver for hot chamber

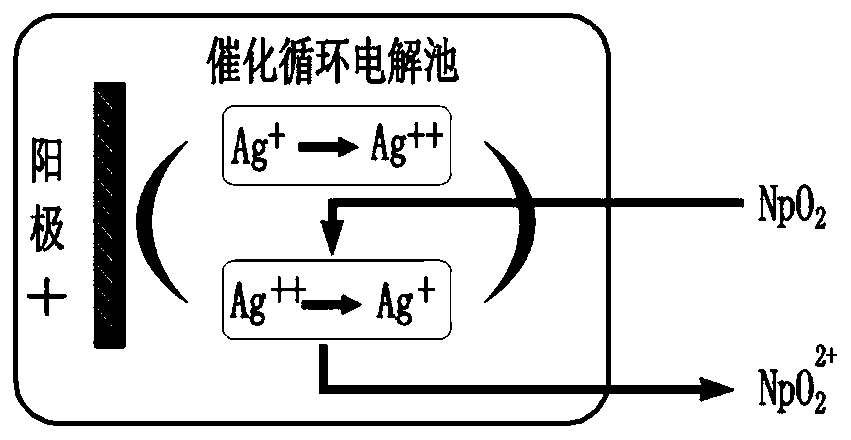

A neptunium dioxide and plutonium dioxide technology, which is applied in the field of neptunium dioxide-plutonium dioxide dissolvers for hot cells, can solve problems such as difficult dissolution of hot nitric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

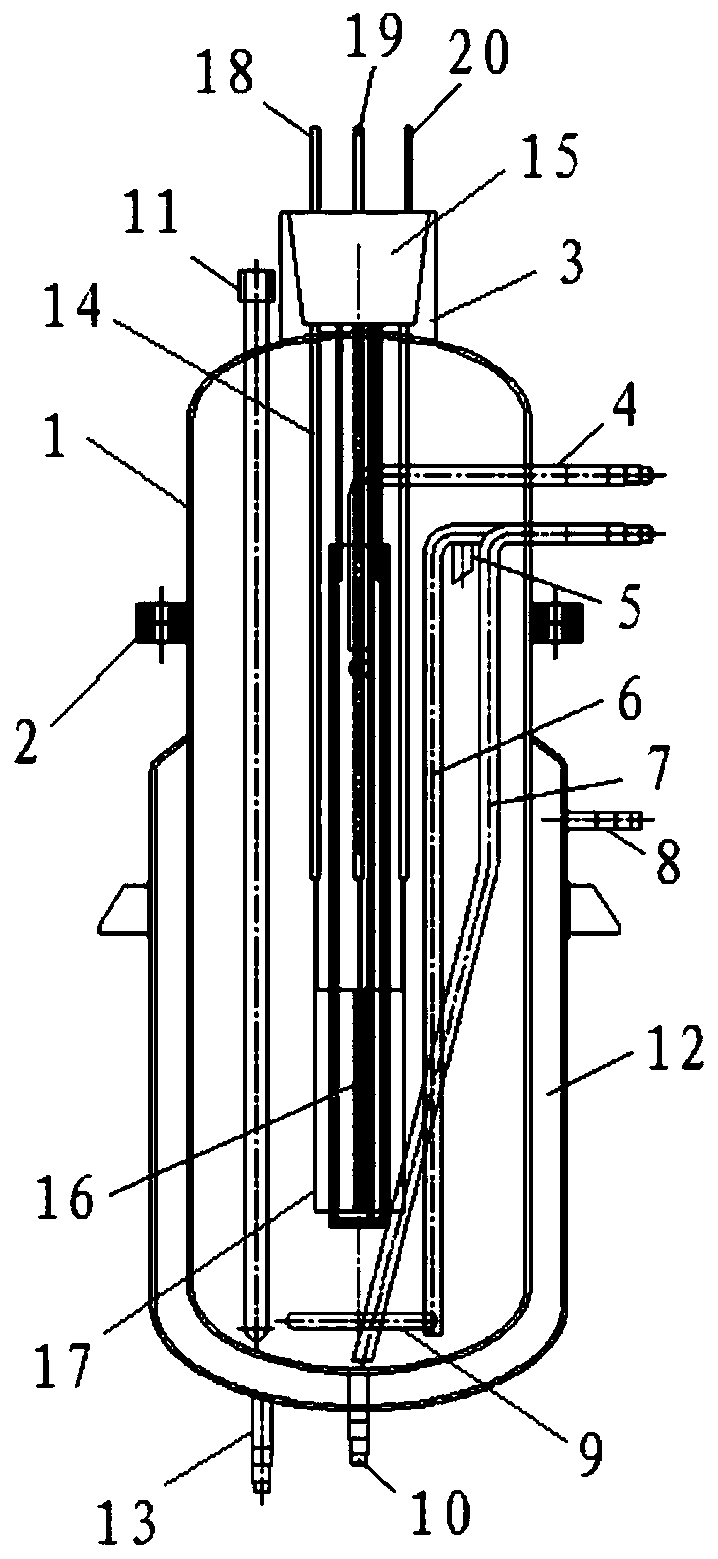

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] A neptunium dioxide-plutonium dioxide dissolver for a hot cell provided by the present invention is used for dissolving a neptunium target containing neptunium and plutonium elements in a hot cell, and is composed of a dissolution tank 1, an integral electrode 14, and a circuit plug Components, hydraulic plug components and control system.

[0030] Such as figure 2 As shown, the dissolution tank 1 is a vertical double elliptical head container (about 1000-1500mm in length, 1000-1500mm in width, and 1500-3000mm in height), resistant to strong acid and high temperature, and made of metal titanium or stainless steel, etc., which are resistant to nitric acid corrosion The material is divided into an upper tank body and a lower tank body. The upper tank body and the lower tank body are connected by a flange 2, and a fluorine rubber sealing ring is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com