Weeding and obstacle-avoiding robot

A robot and obstacle avoidance technology, applied in the direction of instruments, motor vehicles, land preparation machinery, etc., can solve the problems of manual removal, low level of intelligence, poor operator comfort, etc., to achieve the effect of avoiding injuries and large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

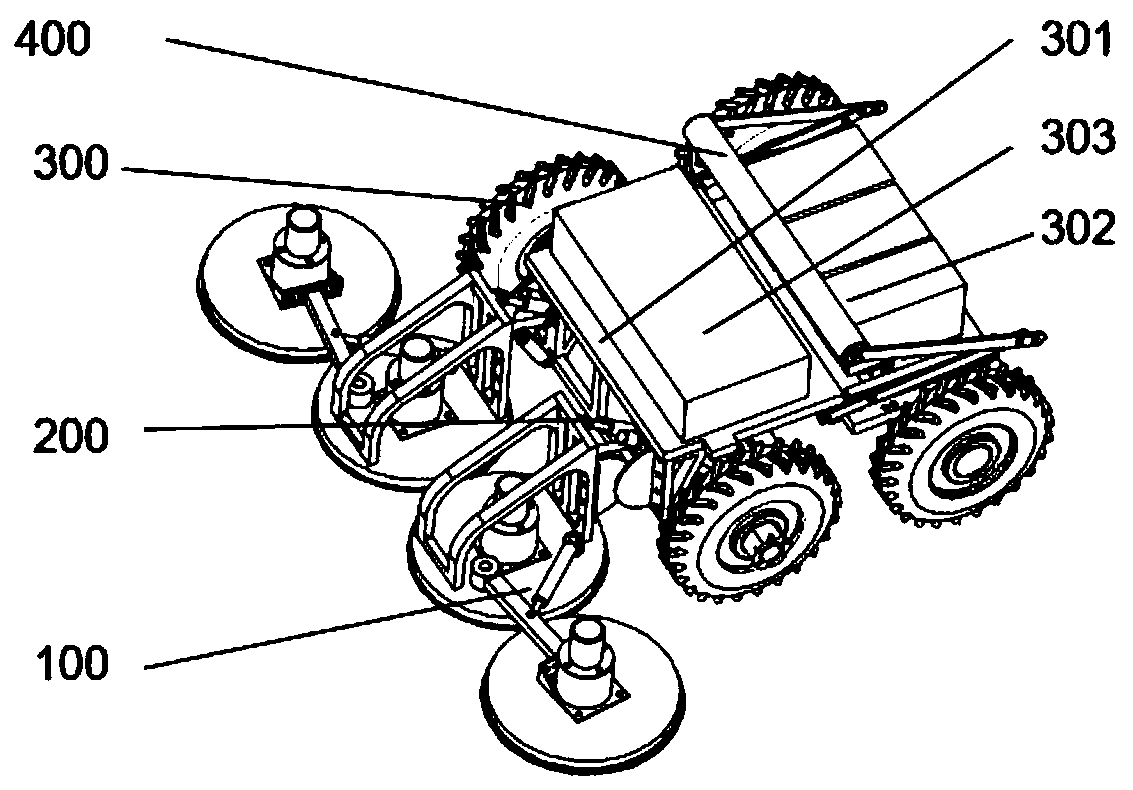

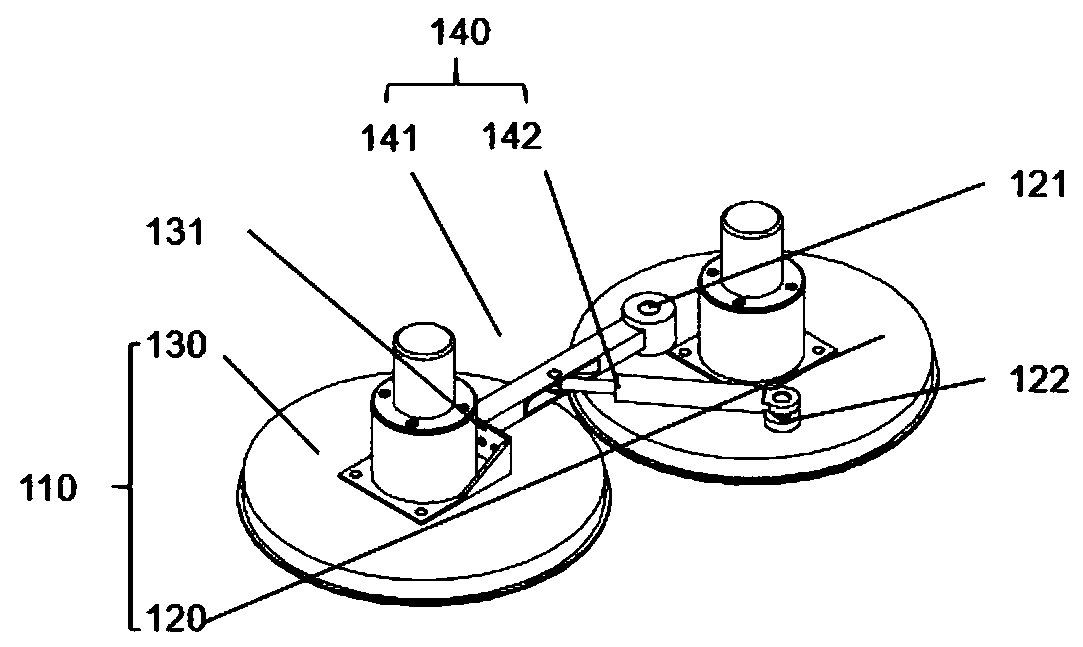

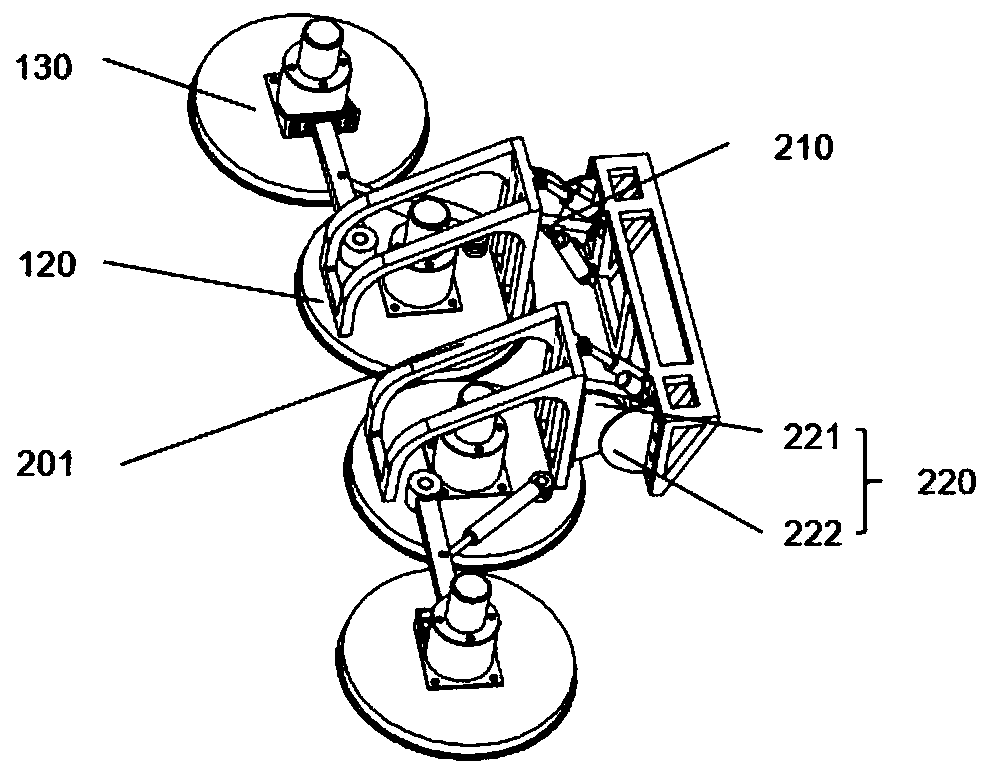

[0047] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached Figure 1-12 Specific embodiments of the present invention are described in detail.

[0048] See attached figure 1 , the first aspect of the present invention provides a weeding and obstacle avoidance robot, including a weeding and obstacle avoidance mechanism 100, a cutter head adjustment mechanism 200, and a mobile platform 300; the cutter head adjustment mechanism 200 is used to adjust the height and / or inclination of the cutter head Angle; one end of the cutter head adjustment mechanism 200 is connected to the weeding and obstacle avoidance mechanism 100 , and the other end of the cutter head adjustment mechanism 200 is connected to the mobile platform 300 .

[0049] Therefore, the present invention can effectively avoid obstacles while automatically weeding by setting the weeding and obstacl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com