A welding device for a mask production machine

A production machine and welding technology, which is applied to clothing, tools for sewing clothes, protective clothing, etc., can solve the problems of poor three-dimensionality, low welding efficiency of nose strips, and poor mask version, so as to improve the feeding speed and reduce the Carrying action, high synchronization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

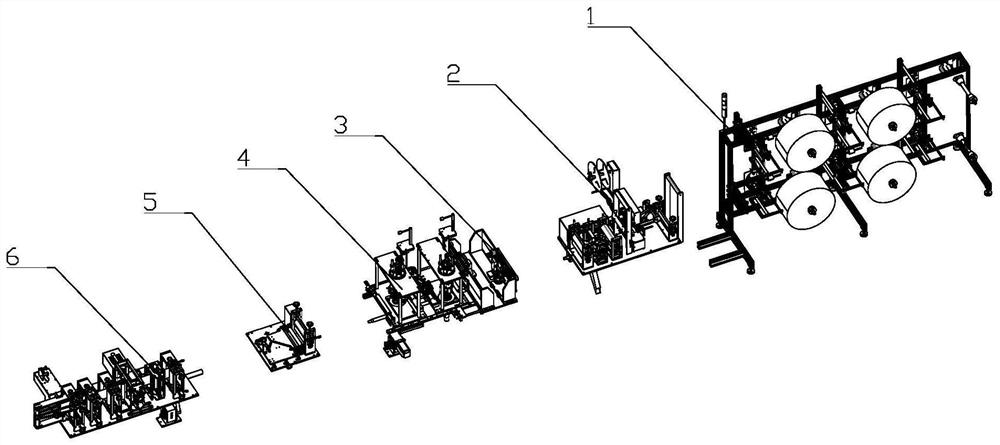

[0035] like figure 1 As shown, a mask production machine includes a cloth feeding device 1, a welding device 2, a pad printing device 3, an earband welding device 4, a creasing device 5 and a die-cutting and shaping device 6; along the direction of processing, the cloth The feeding device 1 , the welding device 2 , the pad printing device 3 , the earband welding device 4 , the creasing device 5 and the die-cutting and shaping device 6 are successively connected.

[0036] The cloth feeding device 1 is used to convey the cloths of various materials, and the welding device 2 is used to weld the multi-layer cloths together and weld the nose strips on the mask surface; the pad printing The device 3 is used to print corresponding patterns on the mask surface; the ear strap welding device 4 is used to weld two ear straps on both sides of the mask, and the creasing device 5 is used to crimp the mask. The die-cutting and shaping device 6 described above is used for shaping and cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com