Stirring device for latex microsphere dispersion, dispersion equipment and method

A stirring device and dispersing technology are applied in mixers with rotary stirring devices, chemical instruments and methods, preparation of samples for testing, etc. Production efficiency and other issues, to achieve the effect of high uniformity, good stirring effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The utility model will be further described below in conjunction with the accompanying drawings and specific embodiments.

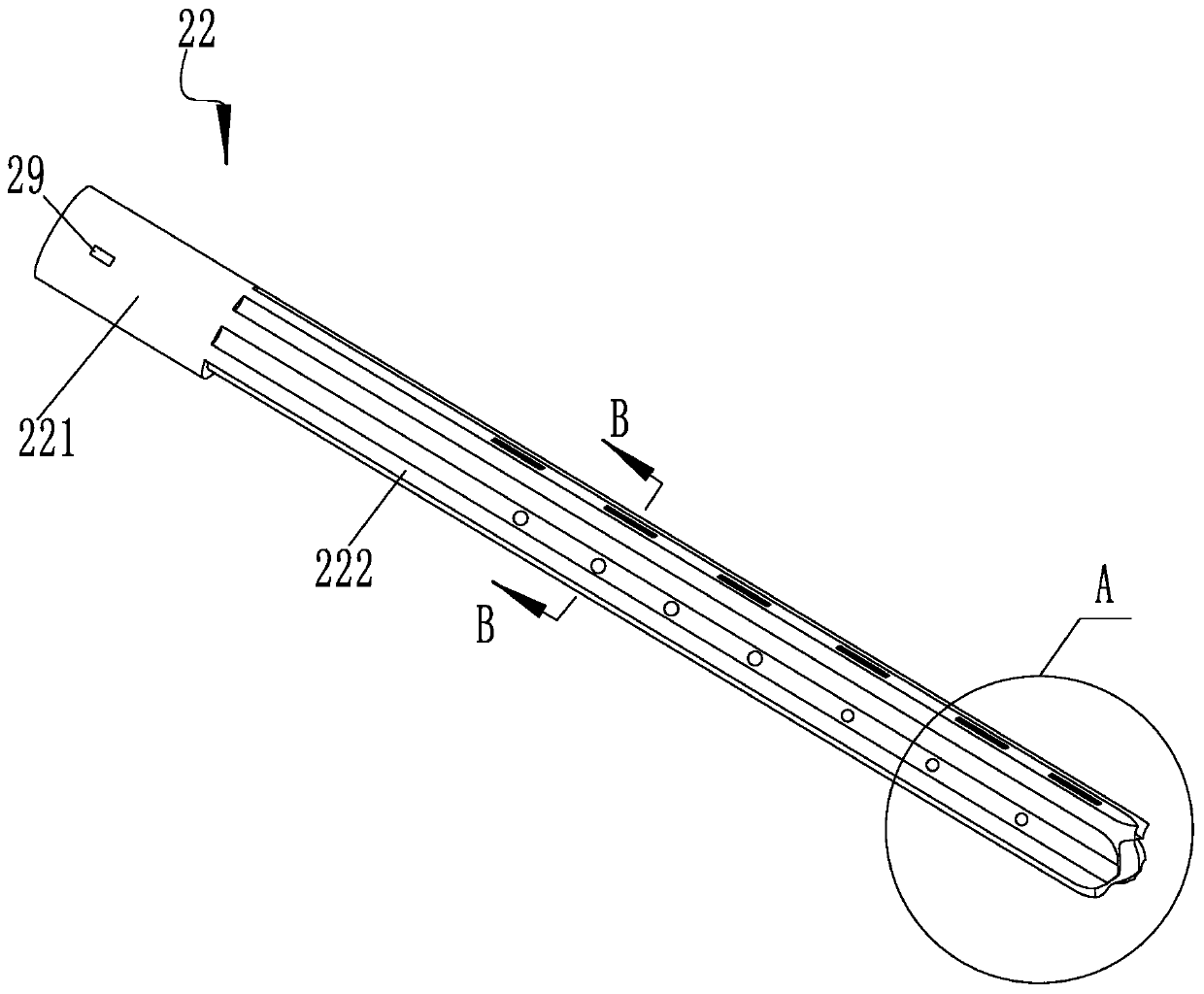

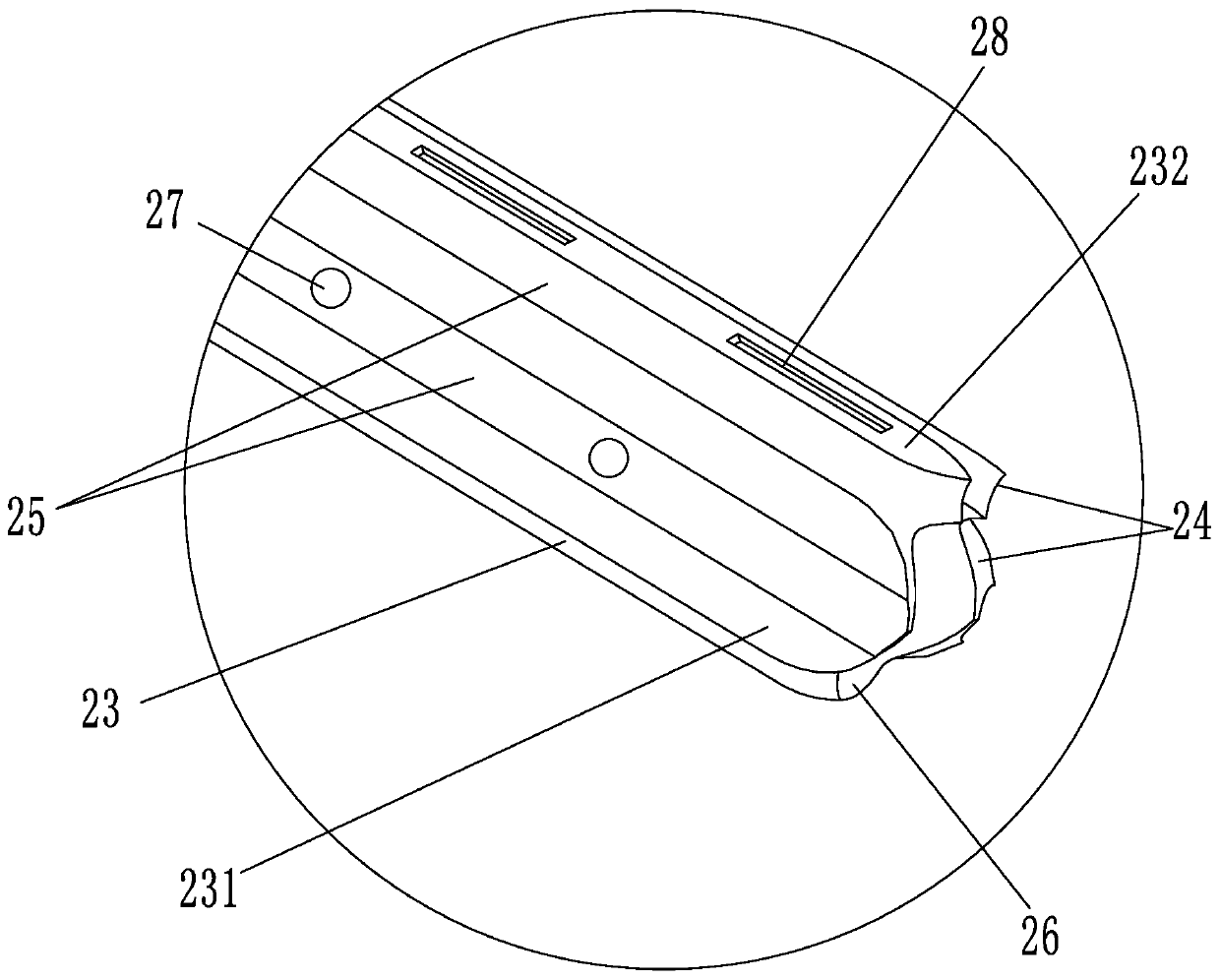

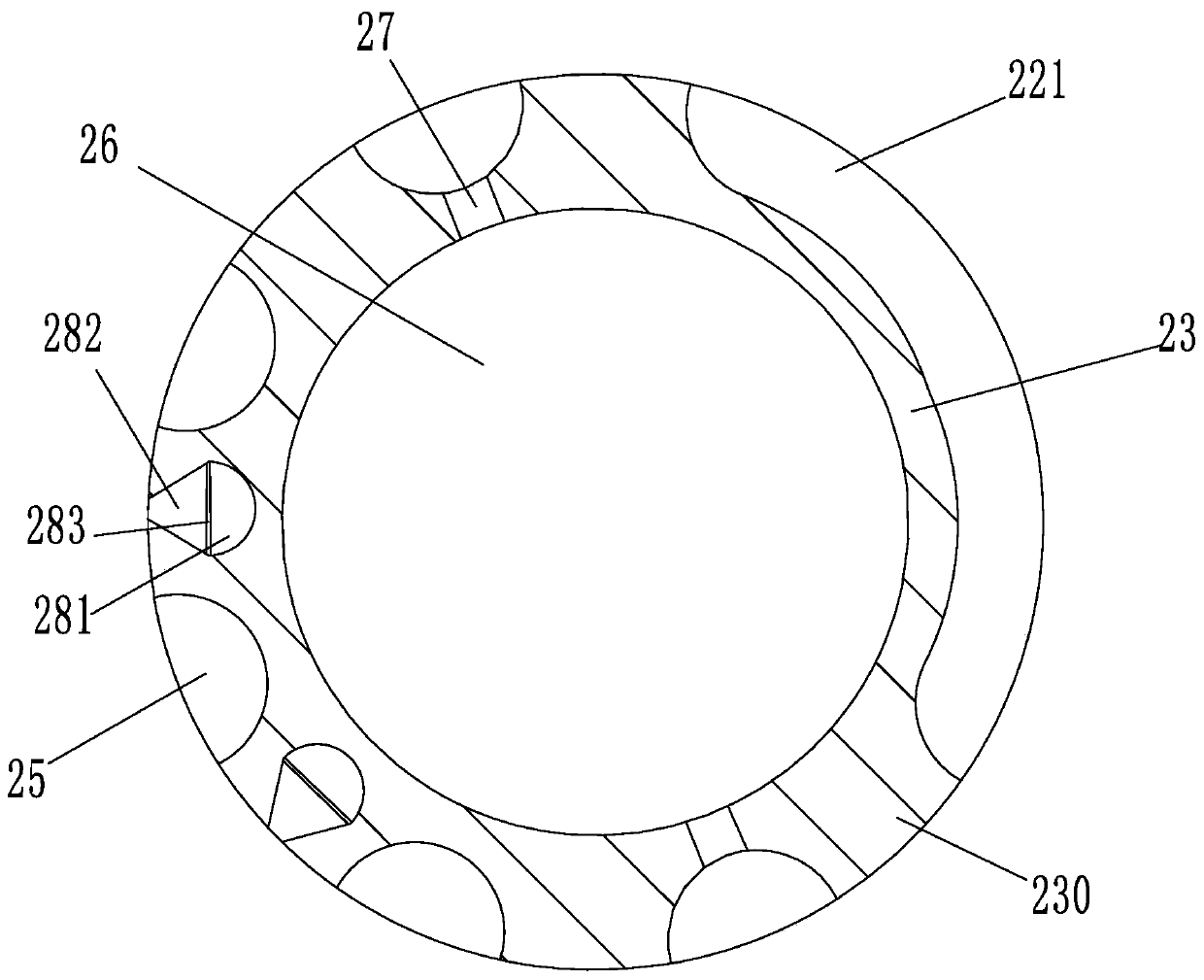

[0028] Such as Figures 1 to 3 The shown embodiment is a stirring device for dispersion of latex microspheres, comprising a stirring end 222 and a connecting end 221 connected to a driving element, the connecting end 221 is cylindrical, and the driving element adopts a direct connection with the connecting end 221 through a coupling. The connecting end 221 side is provided with four pressure sensors 29 arrayed about the axis of the connecting end 221. In practical application, the pressure sensor 29 is located between the shaft coupling and the connecting end 221 . In addition, a torque sensor can also be used, and the torque sensor can be directly arranged outside the connecting end 221 . The stirring rod 23 rotates synchronously with the driving motor, the driving motor drives the stirring rod 23 to rotate, and the stirring paddle 230 completes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com