Negative ion flame-retardant high-temperature-resistant nano-silicon modified antibacterial engineering plastic master batch

A technology of plastic masterbatch and engineering plastics, applied in the field of plastic masterbatch, can solve the problem of not giving engineering plastics health care functions such as air purification, release negative ions and far infrared rays, etc., and achieve good health care effects, good flame retardant and high temperature resistance, Glossy impact resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

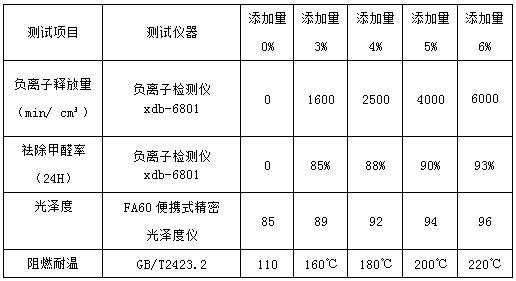

Image

Examples

Embodiment 1

[0015] The components and weight components of the plastic masterbatch are: 500 parts of nano-scale anion powder, 50 parts of nano-antimony oxide, 450 parts of nano-silicon, 3 parts of emulsifier, 3 parts of alignment agent, 3 parts of wetting and dispersing agent, deionized water 300 copies.

Embodiment 2

[0017] The components and weight components of the plastic masterbatch are: 500 parts of nano-scale anion powder, 100 parts of nano-antimony oxide, 400 parts of nano-silicon, 3 parts of emulsifier, 3 parts of alignment agent, 3 parts of wetting and dispersing agent, deionized water 300 copies.

Embodiment 3

[0019] The components and weight components of the plastic masterbatch are: 400 parts of nano-scale anion powder, 200 parts of nano-antimony oxide, 400 parts of nano-silicon, 3 parts of emulsifier, 3 parts of alignment agent, 3 parts of wetting and dispersing agent, deionized water 240 copies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com