Preparation method of rare earth inorganic composite material with high luminous intensity

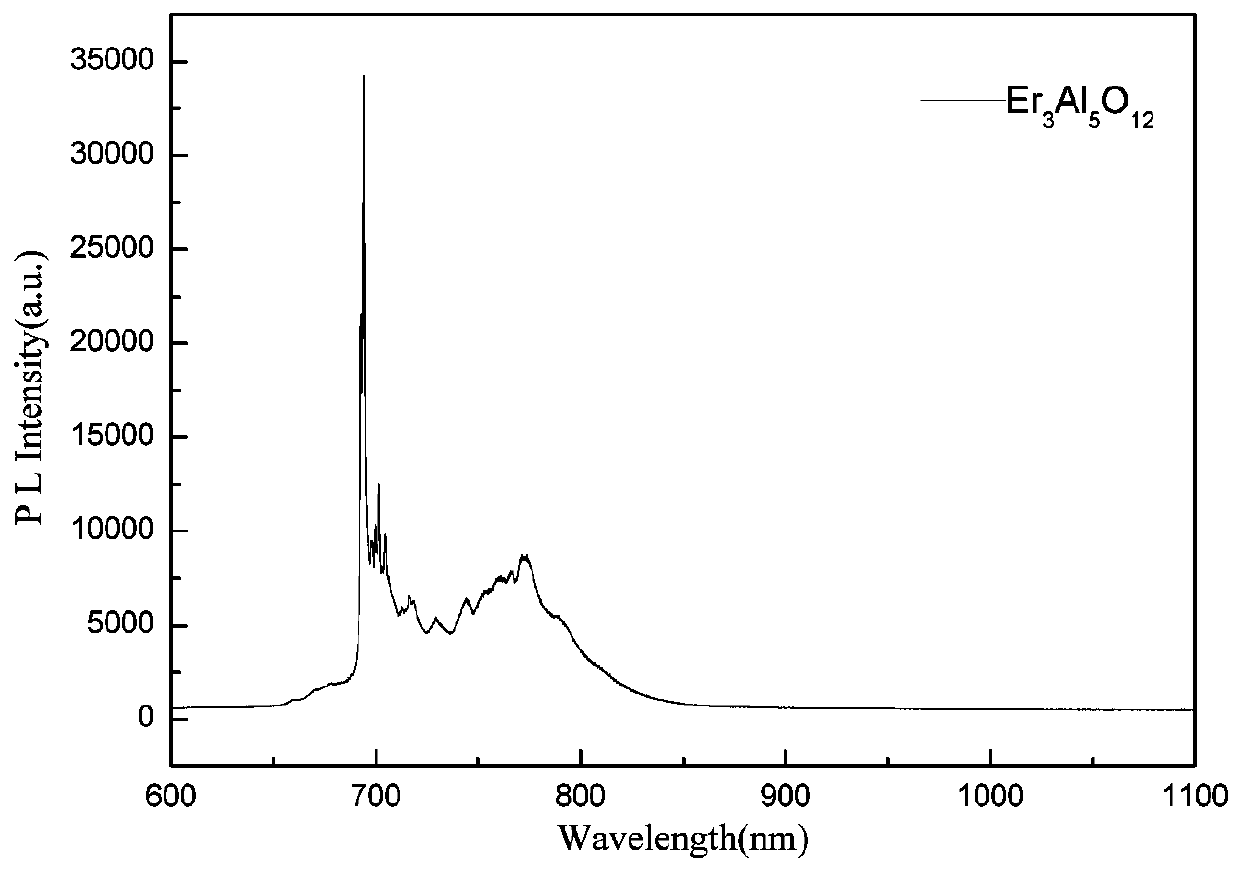

A luminous intensity, rare earth inorganic technology, applied in luminescent materials, chemical instruments and methods, etc., can solve problems such as poor luminous intensity, and achieve the effects of narrow peak width, high intensity, and superior luminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

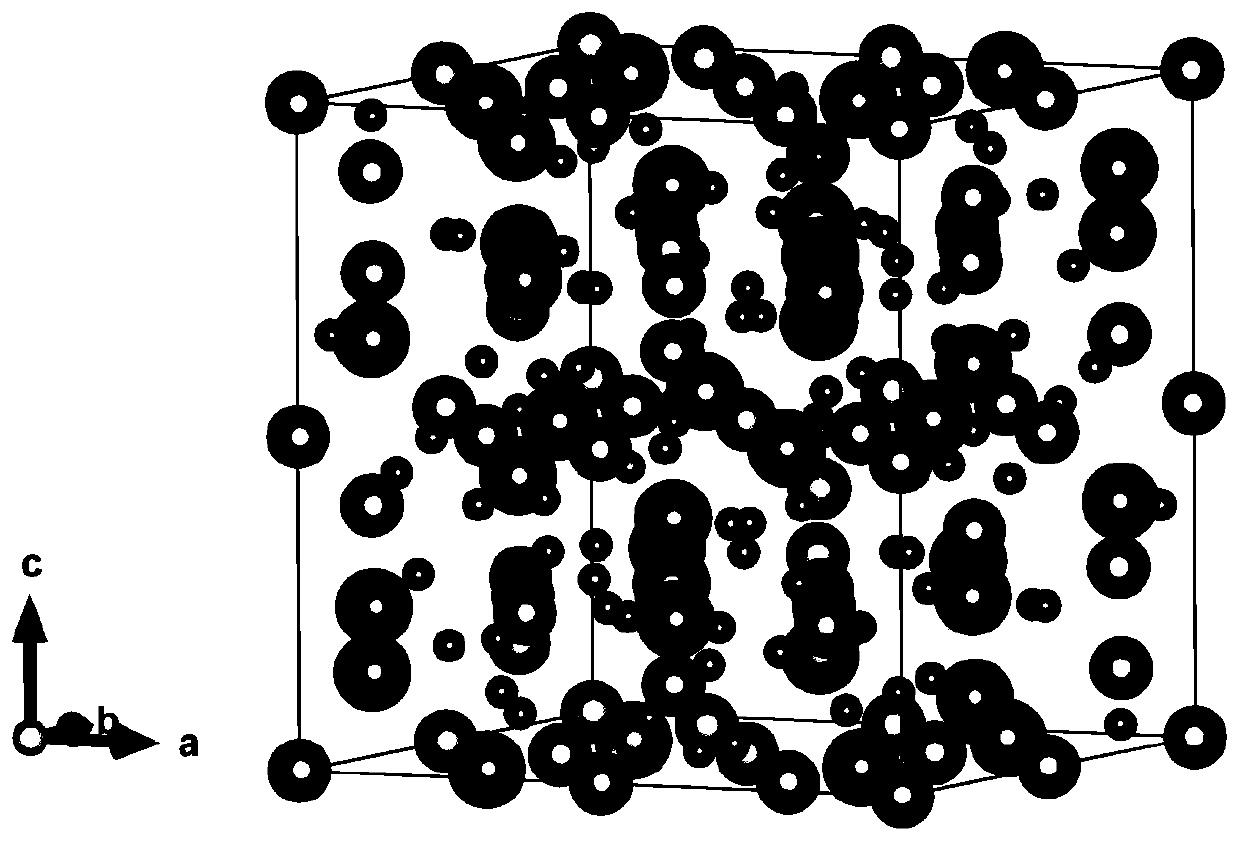

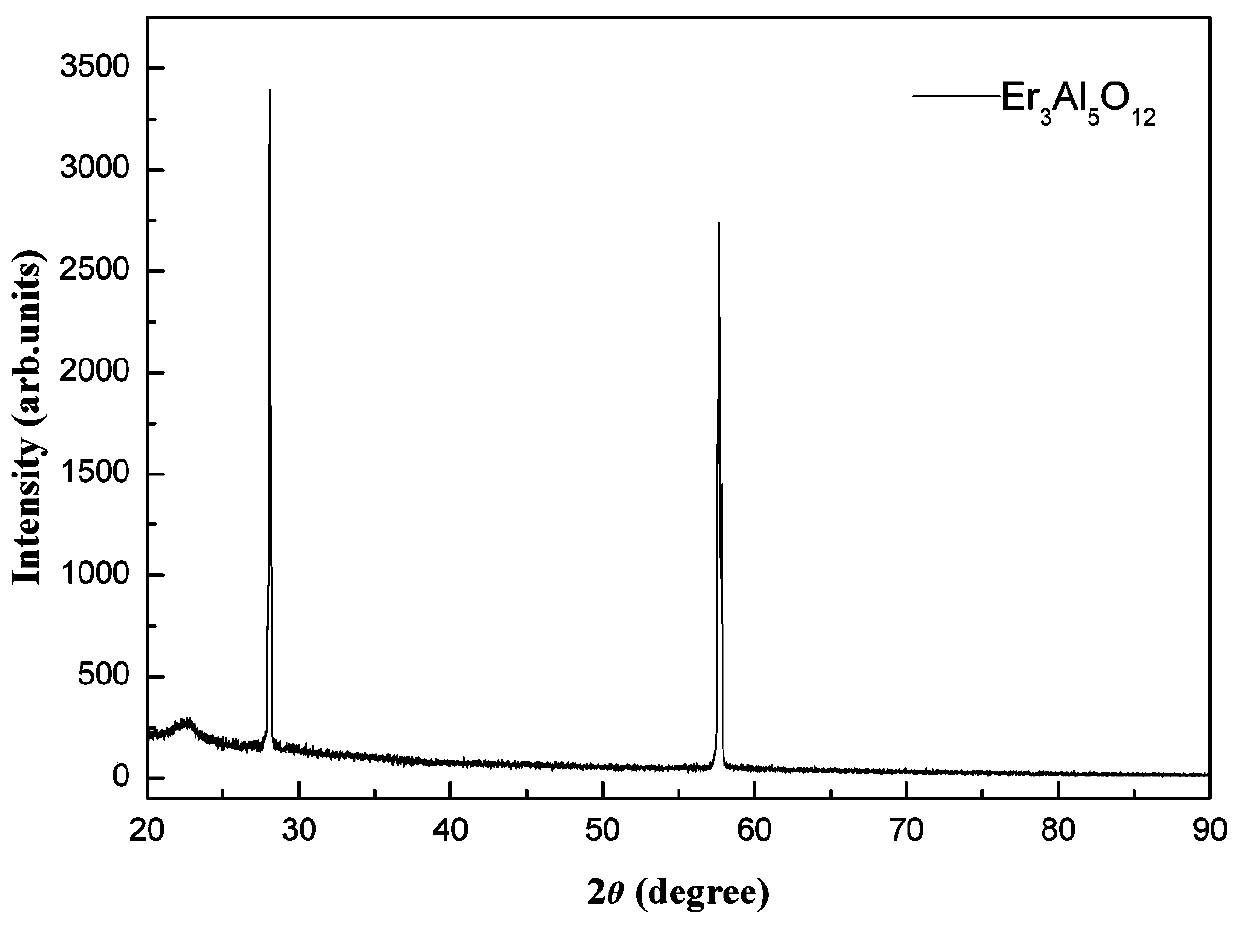

Image

Examples

Embodiment 1

[0025] A preparation method of a rare earth inorganic composite material with high luminous intensity in this embodiment comprises the following steps:

[0026] Step 1, raw material mixing: Er, Cr 2 o 3 , PbF 2 , PbO, H 3 BO 3 Carry out mixing process according to the weight ratio of 1:1:8:2:2;

[0027] Step 2, pre-activation treatment: preheat the raw materials mixed in step 1 to 60°C, then conduct heat preservation treatment, and then send them into the reactor for variable temperature and pressure treatment;

[0028] Step 3, deep activation treatment: the material after pre-activation treatment is treated with corona first, the corona field strength is 160KV / m, the corona time is 15min, and then the 60 co r Radiation source excitation treatment;

[0029] Step 4, alumina crucible sintering treatment: send the deeply activated material into the alumina crucible, firstly the natural temperature rises to 1200°C, then keeps the temperature for 96h, then drops to 1000°C at...

Embodiment 2

[0035] A preparation method of a rare earth inorganic composite material with high luminous intensity in this embodiment comprises the following steps:

[0036] Step 1, raw material mixing: Er, Cr 2 o 3 , PbF 2 , PbO, H 3 BO 3 Carry out mixing process according to the weight ratio of 1:1:8:2:2;

[0037] Step 2, pre-activation treatment: preheat the raw materials mixed in step 1 to 100°C, then perform heat preservation treatment, and then send them into the reactor for variable temperature and pressure treatment;

[0038] Step 3, deep activation treatment: the material after pre-activation treatment is treated with corona first, the corona field strength is 220KV / m, and the corona time is 25min, and then use 60 co r Radiation source excitation treatment;

[0039] Step 4, alumina crucible sintering treatment: send the deeply activated material into the alumina crucible, firstly the natural temperature rises to 1200°C, then keeps the temperature for 96h, then drops to 1000...

Embodiment 3

[0045] A preparation method of a rare earth inorganic composite material with high luminous intensity in this embodiment comprises the following steps:

[0046] Step 1, raw material mixing: Er, Cr 2 o 3 , PbF 2 , PbO, H 3 BO 3Carry out mixing process according to the weight ratio of 1:1:8:2:2;

[0047] Step 2, pre-activation treatment: preheat the raw materials mixed in step 1 to 80°C, then conduct heat preservation treatment, and then send them into the reactor for variable temperature and pressure treatment;

[0048] Step 3, deep activation treatment: the material after pre-activation treatment is first treated with corona, the corona field strength is 180KV / m, and the corona time is 20min, and then use 60 co r Radiation source excitation treatment;

[0049] Step 4, alumina crucible sintering treatment: send the deeply activated material into the alumina crucible, firstly the natural temperature rises to 1200°C, then keeps the temperature for 96h, then drops to 1000°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com