U-shaped magnetic levitation rail transit beam

A magnetic levitation track and transportation technology, which is applied in the field of rail transportation, can solve problems such as safety problems of high-altitude operations, inconvenient daily maintenance, etc., and achieve the effect of matching and harmonious appearance with the environment, large working space, and increased lateral rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

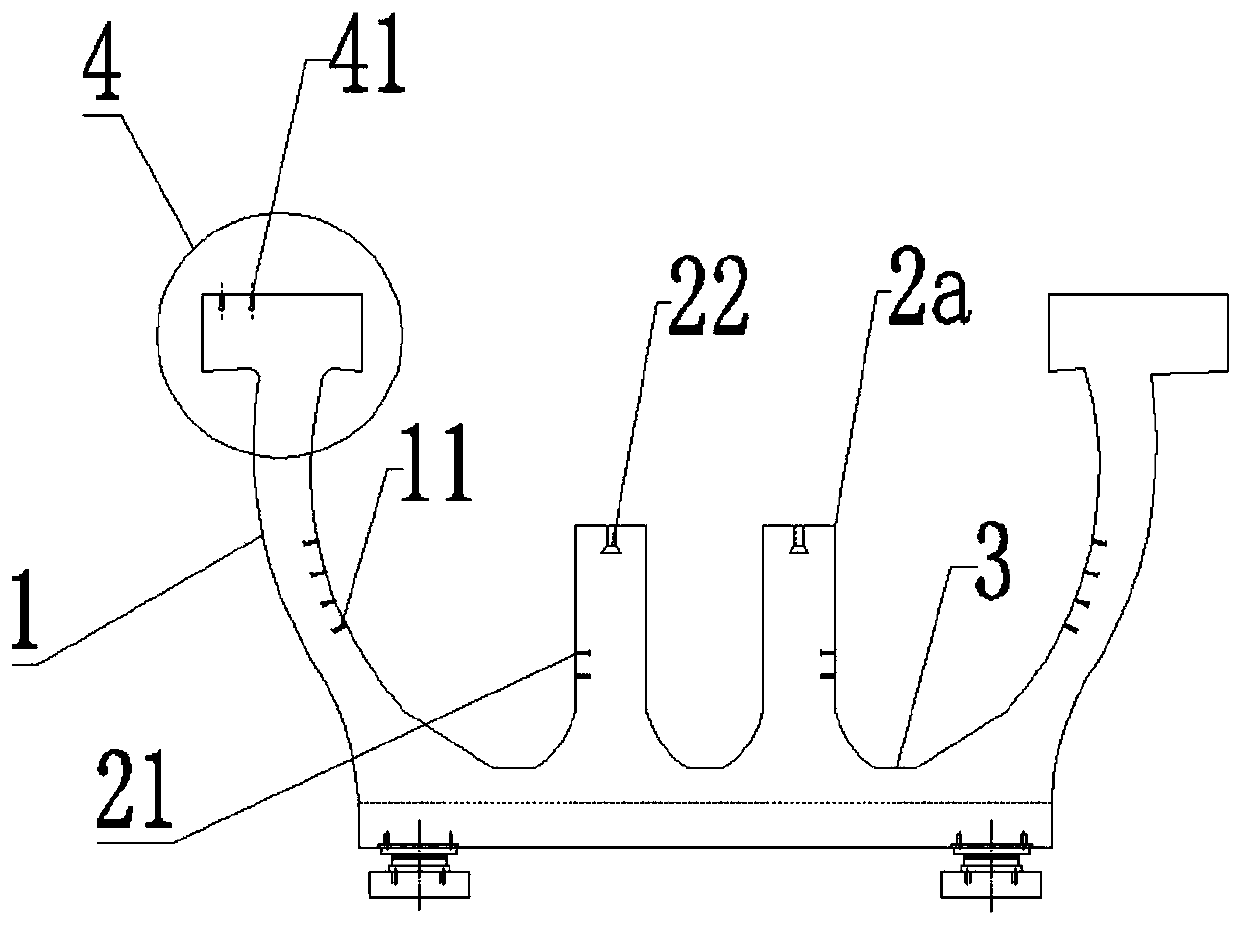

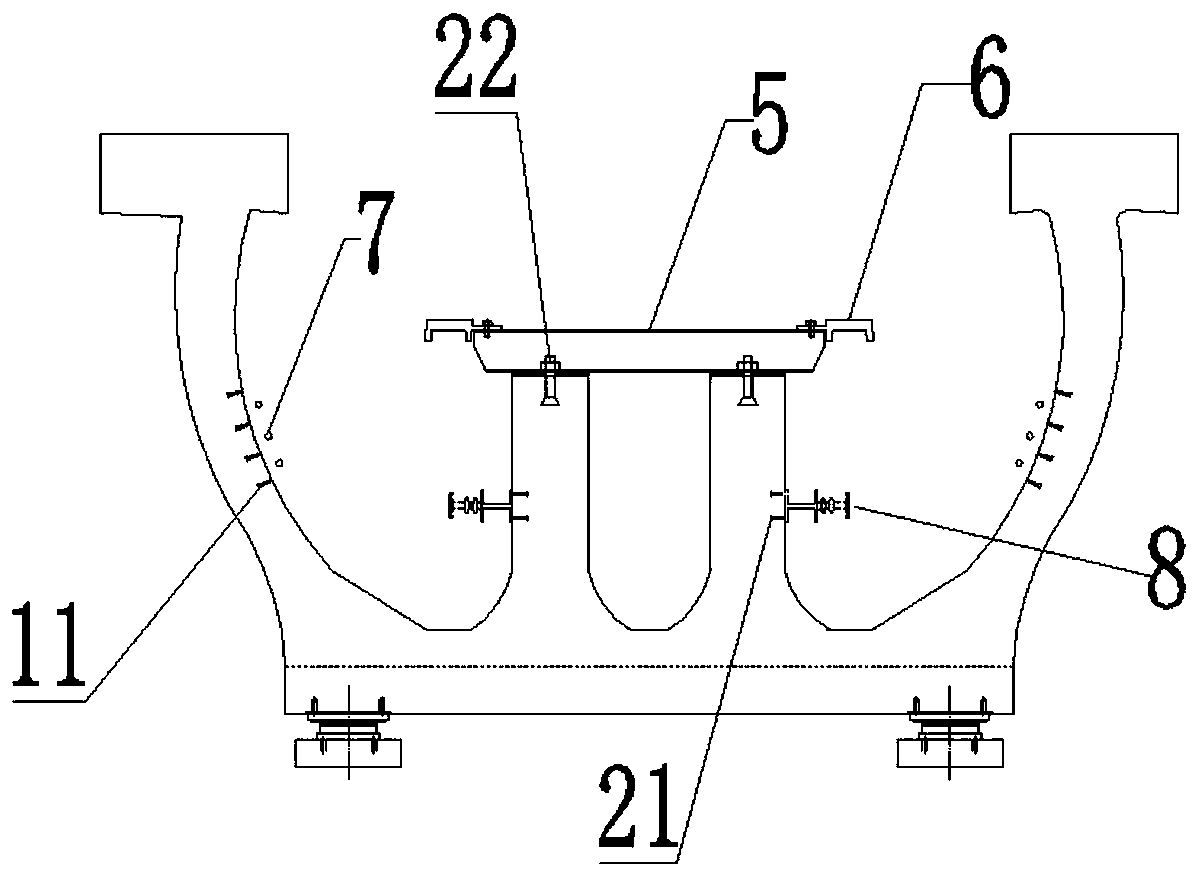

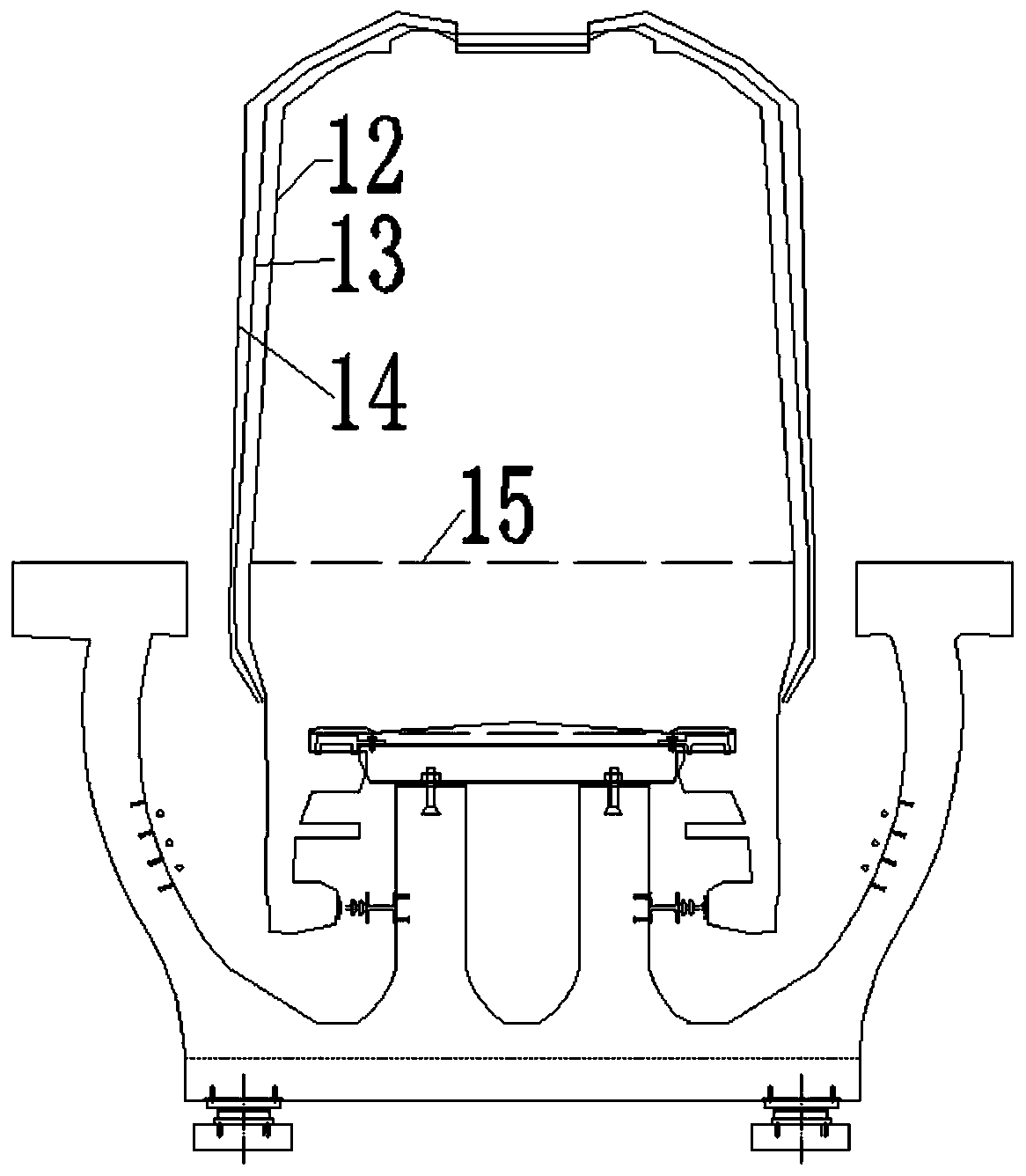

[0038] Such as figure 1 Shown is the sectional structure of a single-line rail transit beam with a built-in U-shaped track support, including an outer U-shaped beam body 1 and a U-shaped track support 2a placed inside the beam body 1 . Wherein, the bottom of the U-shaped track support 2a is integrated with the bottom of the beam body 1, and the whole adopts a prestressed reinforced concrete structure.

[0039] In addition, the two arms of the beam body 1 are two wing plates, and wing edges 4 are arranged on the top of the wing plates, and a number of fourth embedded nuts 41 for installing sound barriers are arranged on the outside of the top surface of the wing edges 4 . Among them, the outer width of the top surface of the wing edge 4 should not be less than 800mm, so as to facilitate the installation of equipment such as signal and sound barriers.

[0040] On the inner wall of the beam body 1, there are several first embedded nuts 11 for installing the cables 7; where the ...

Embodiment 2

[0054] Such as Figure 6 As shown in , another implementation structure of this program is to change the structure of the U-shaped track support 2a in Example 1 into a Π-shaped track support 2b, and keep other parts unchanged. After this change, its advantage is: the magnetic levitation plate 6 can be directly installed on the two ends of the Π-shaped track support 2b, so that the steel sleeper can be saved, thereby further reducing the total investment cost of the magnetic levitation rail transit.

[0055] Among them, the section structure of the double-line rail transit beam with built-in Π-shaped track support, such as Figure 7 As shown, on the pier 10, two double-line rail transit beams with built-in Π-shaped track supports are arranged side by side in parallel, and in the middle, two wing edges 4 are spliced together to directly form an emergency evacuation passage 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outside width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com