Circuit structure and manufacturing method thereof

A technology of circuit structure and manufacturing method, applied in the direction of circuits, semiconductor/solid-state device parts, nanotechnology for materials and surface science, etc., can solve problems such as peeling and fracture, achieve increased structural strength, simple process steps, The effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Order to more fully illustrate the embodiments of the present invention with reference to the drawings. However, the present invention may be embodied in various different forms and should not be limited to the embodiments described herein. FIG. Layer with a thickness in the region of the figures will be exaggerated for clarity. The same or similar reference numerals designate the same elements or similar elements, it will not further described in the following paragraphs.

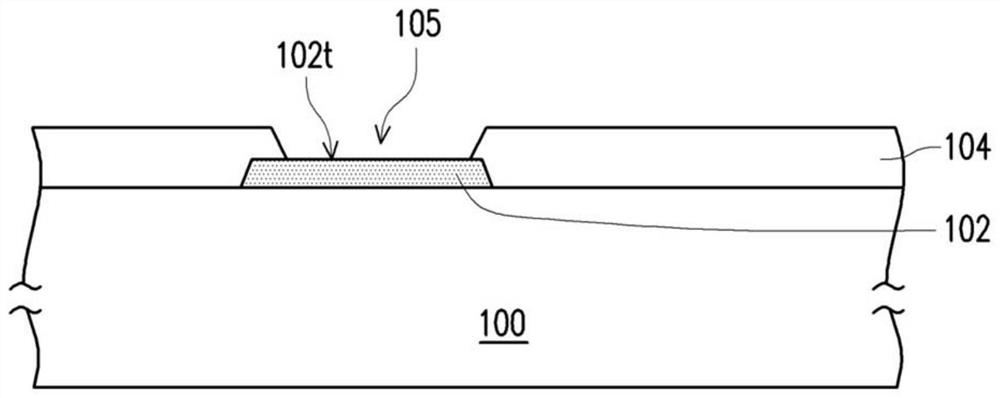

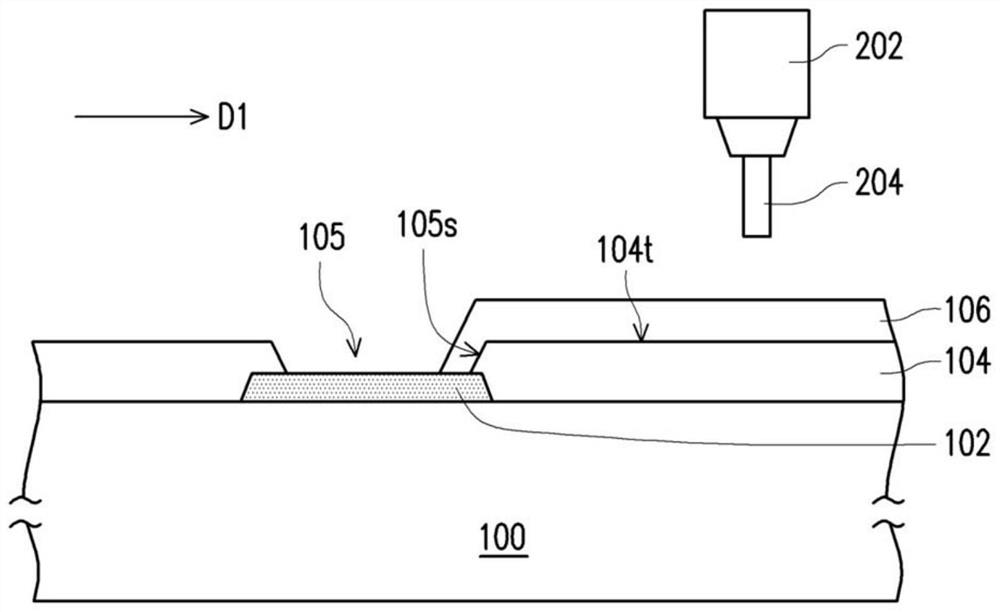

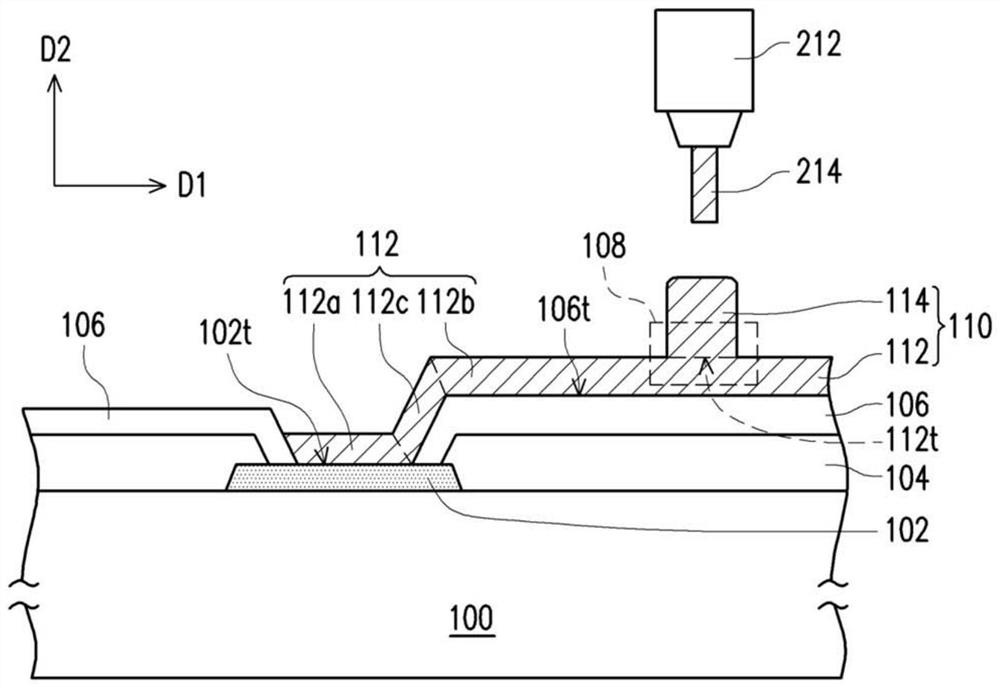

[0012] Figure 1A to 1E It is a schematic diagram cross-sectional manufacturing process a wiring structure according to an embodiment of the present invention. figure 2 Yes Figure 1C A cross-sectional view of a portion of an enlarged view of line structure. Thereto, the present embodiment illustrated embodiment may be a wiring structure redistribution layer (RDL) structure, but the present invention is not limited thereto. In other embodiments, the structure may be a line rear section (back-end-of-line,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com