Method for longitudinal processing using anti-spherical-aberration correction and application

A spherical aberration and longitudinal technology, applied in the field of micro-optical element processing, can solve the problems of unfavorable device miniaturization, long processing time, grating interlacing, etc., and achieve the goal of improving processing efficiency and structural quality, improving processing resolution, and increasing processing depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

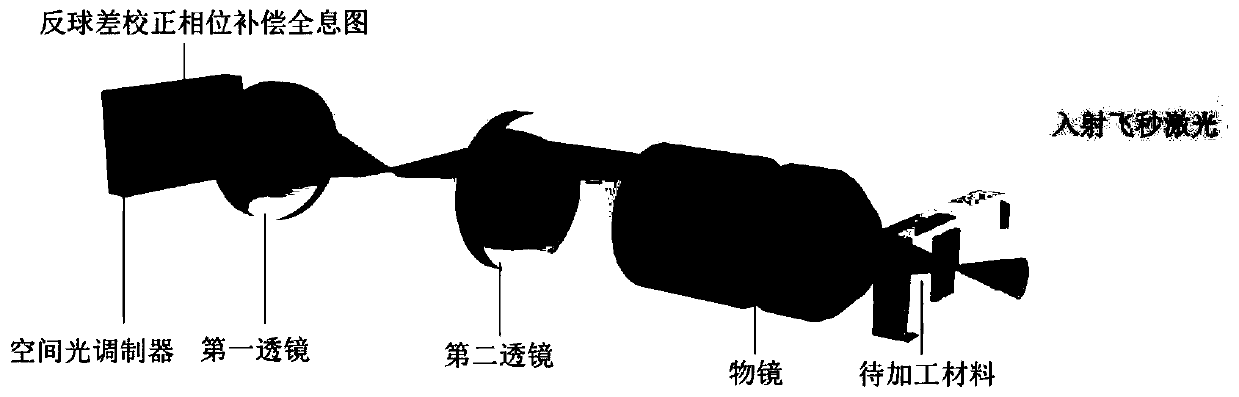

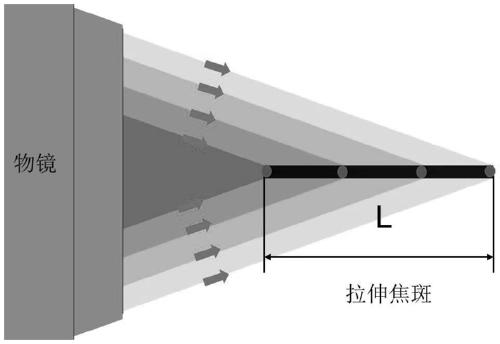

[0030] Obtain a stretched focal spot inside the material to be processed using inverse spherical aberration correction.

[0031] According to the Booth formula, the femtosecond laser focus focused inside the material to be processed is phase modulated, that is, the phase compensation factor s is expanded from the original single value to the interval [s-f st / 2, s+f st / 2], so that the focal spot is significantly stretched in the longitudinal direction, so as to obtain a linear focal spot that can be processed longitudinally with a large aspect ratio.

[0032] Using inverse spherical aberration correction to obtain stretched focal spots inside the material to be processed, the specific steps are as follows:

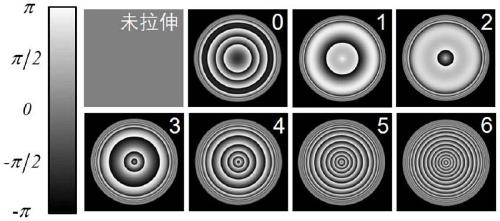

[0033] (1) Expand the compensation factor s to obtain aberration-corrected phase-compensated hologram: First, introduce the stretching factor f for the Booth formula st , so that the value of the compensation factor s is in [s-f st / 2, s+f st / 2], that is, to expand t...

Embodiment 2

[0040] Fabrication of nano-grating structures with large aspect ratio by using stretched focal spot.

[0041] When the repetition frequency of the femtosecond laser is high, continuous lines or surfaces can be obtained by point-by-point scanning. Use the femtosecond laser focused inside the material to be processed to stretch the focal spot, and scan point by point along the Z-axis direction (set the section where the stretched focal spot is located as the X-Y plane), and obtain a nano-grating structure arranged along the X-Y plane (i.e. a series of equally spaced nanofacets perpendicular to the X-Y plane).

[0042] Using the stretched focal spot to process a nano-grating structure with a large aspect ratio, the specific steps are as follows:

[0043] (1), expand the compensation factor s to obtain the phase compensation hologram of aberration correction: same as embodiment 1, where f is used st The value is 20, corresponding to the expansion interval of s is [s-10, s+10]. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com