An automatic pick-up manipulator for a casting machine

A technology of automatic pick-up and manipulator, which is applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of small range of motion, poor flexibility, and difficulty in meeting the requirements of casting loading, unloading and transportation, etc., and achieve large range of motion, The effect of high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

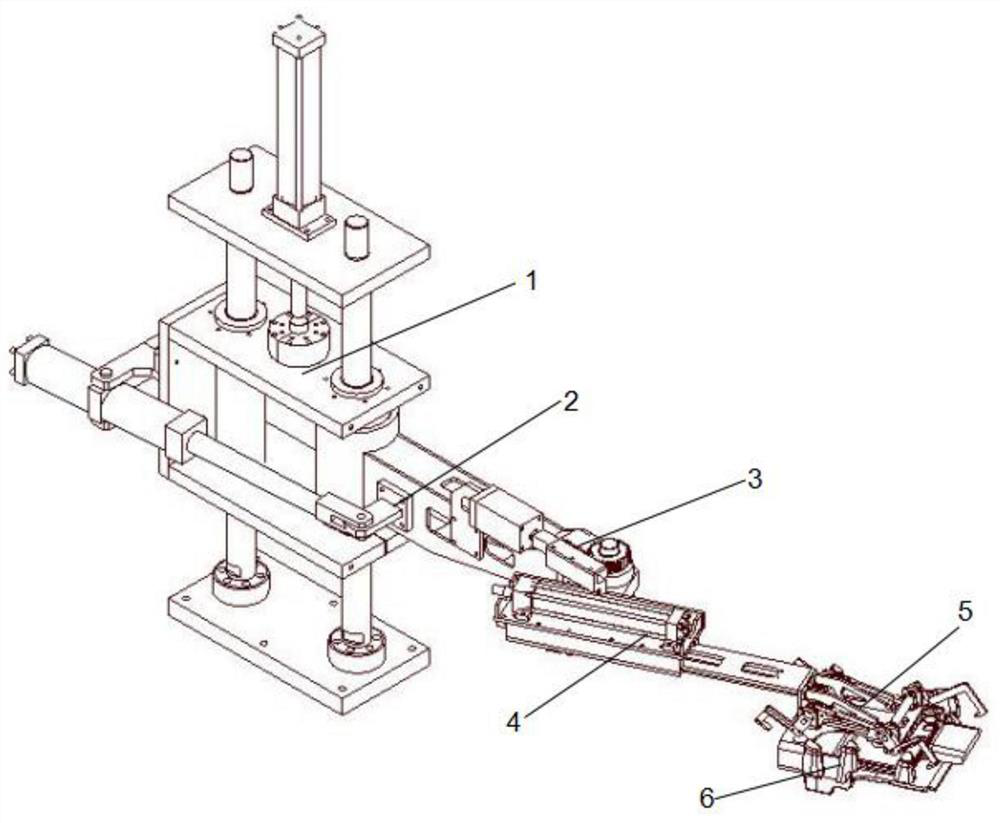

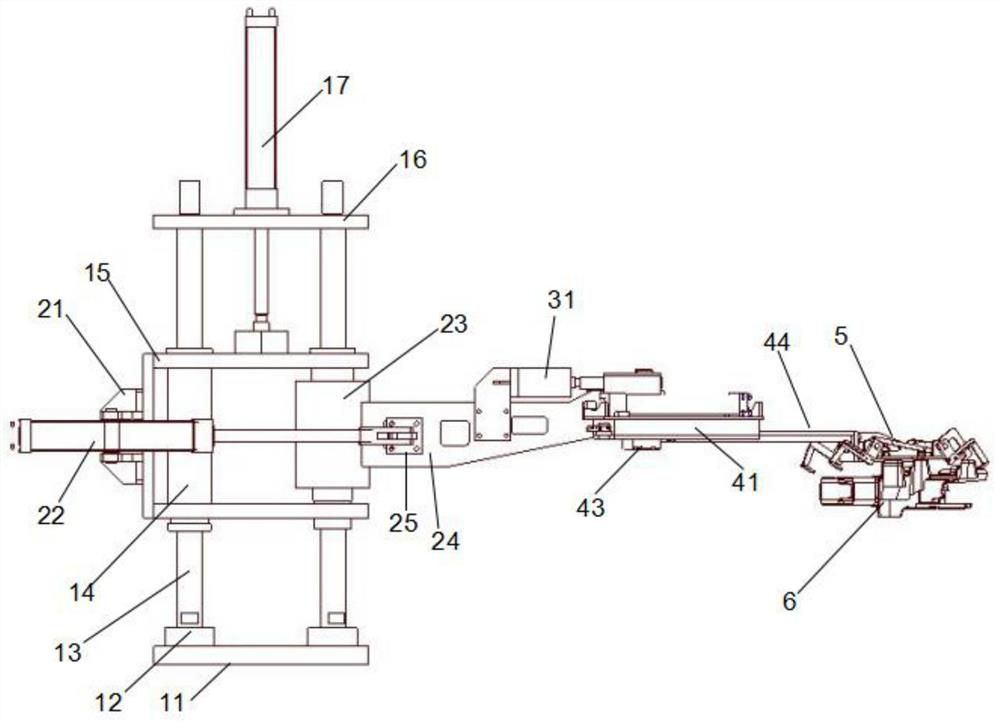

[0023] Embodiment: an automatic pick-up manipulator of a casting machine.

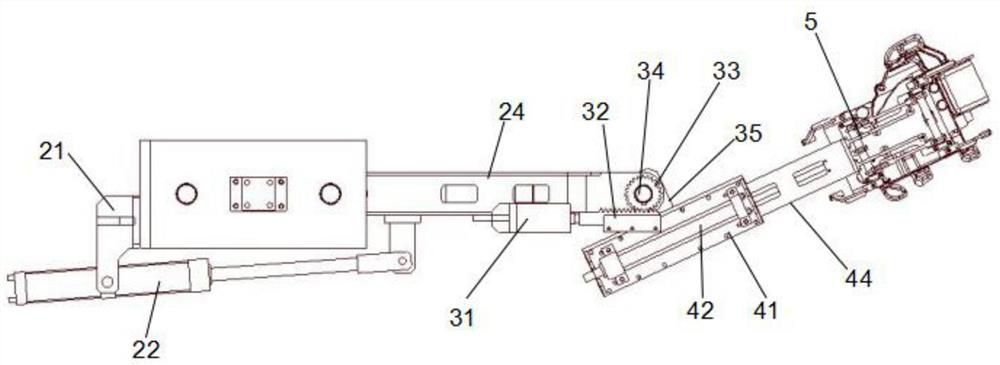

[0024] refer to Figure 1 to Figure 6 As shown, an automatic pick-up manipulator of a casting machine includes:

[0025] Longitudinal drive mechanism 1, described longitudinal drive mechanism 1 comprises base 11, and described base 11 is provided with two guide posts 13 vertically installed side by side, and each guide post 13 is sleeved with moving sleeve 14, and the moving sleeve 14 is equipped with mobile seat 15, and top plate 16 is fixed on guide post 13 tops, and lifting oil cylinder 17 is vertically fixed on the top plate 16 downwards and the telescopic shaft of lifting oil cylinder 17 is fixedly connected with mobile seat 15, and lifting oil cylinder 17 drives mobile seat 15 Moving up and down along the guide post 13, the moving seat 15 includes an upper plate, a lower plate and side plates, wherein the upper plate is fixed between the tops of the two moving sleeves 14, the lower plate is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com