Container feeding device and feeding method

A turnover box and material loading technology, which is applied in the directions of transportation and packaging, object stacking, and object destacking, etc., can solve the problems of low economic benefits and increased floor space of the production line, etc., to achieve the method and control logic Simple, small footprint, reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

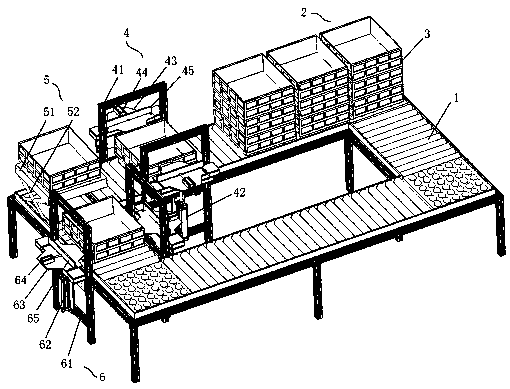

[0035] Example 1. A turnover box feeding device, constituted as figure 1 As shown, it includes an automatic conveying roller table 1, and along the moving direction of the automatic conveying roller table 1, a storage area 2, a destacking area, a retrieval area and a stacking area are arranged in sequence; the storage area 2 is used to store products loaded with The turnover box stack 3; the destacking area is provided with a destacking mechanism 4 for dismantling the turnover box stack 3, so that the dismantled turnover box single box advances; the described taking area is used to take the single box The materials in the turnover boxes; the stacking area is provided with a stacking mechanism 6 for stacking turnover boxes of finished products into turnover box stacks 3 .

[0036] The aforementioned destacking mechanism 4 includes two destacking supports 41 arranged on both sides of the automatic conveying roller table 1 in the destacking area, each destacking support 41 is ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com