Method for producing water-soluble fertilizer by using shells

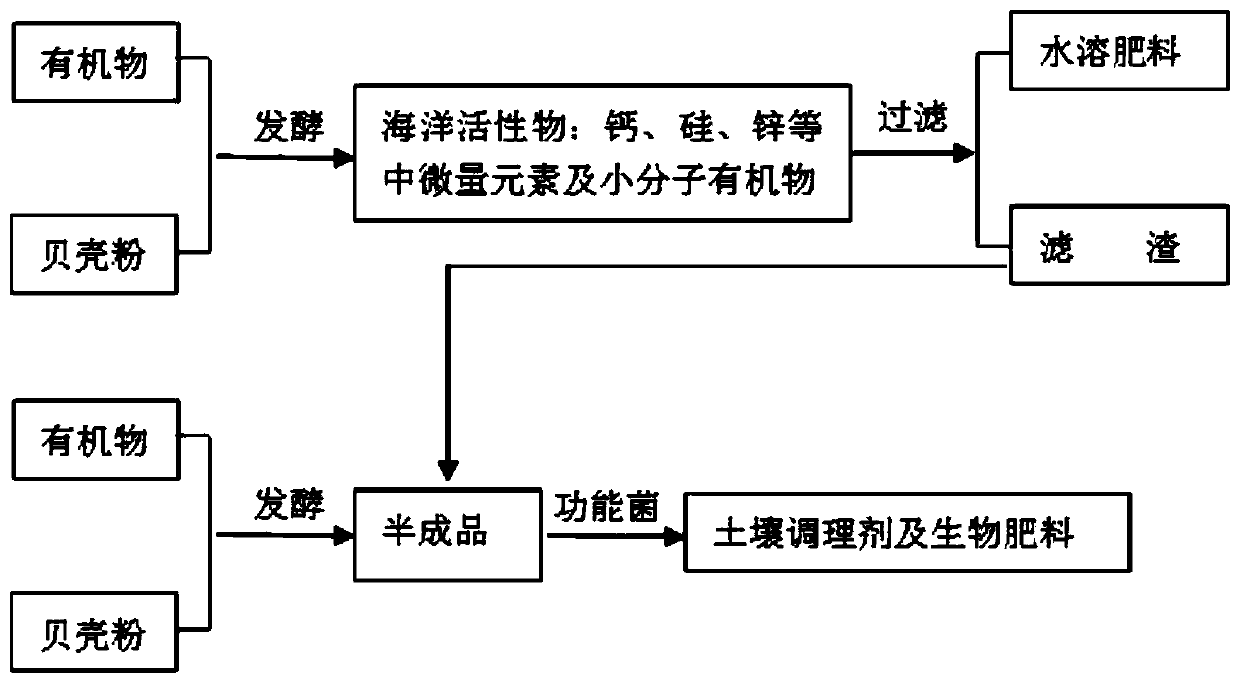

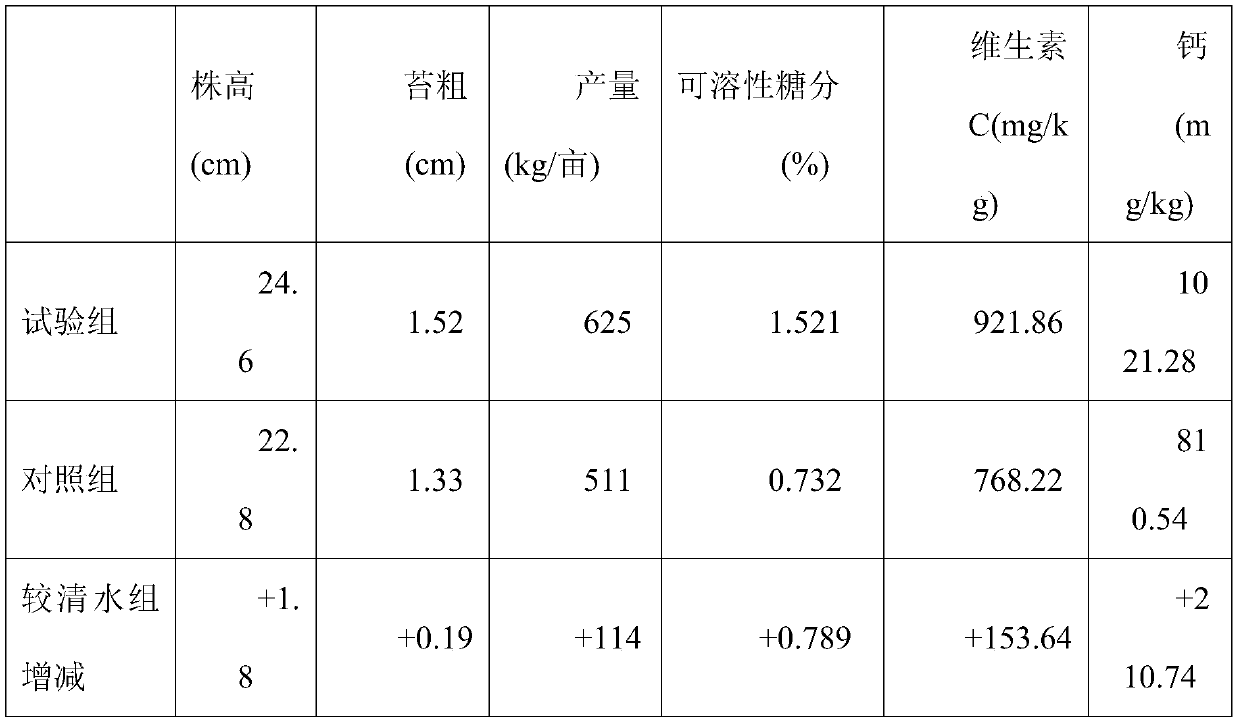

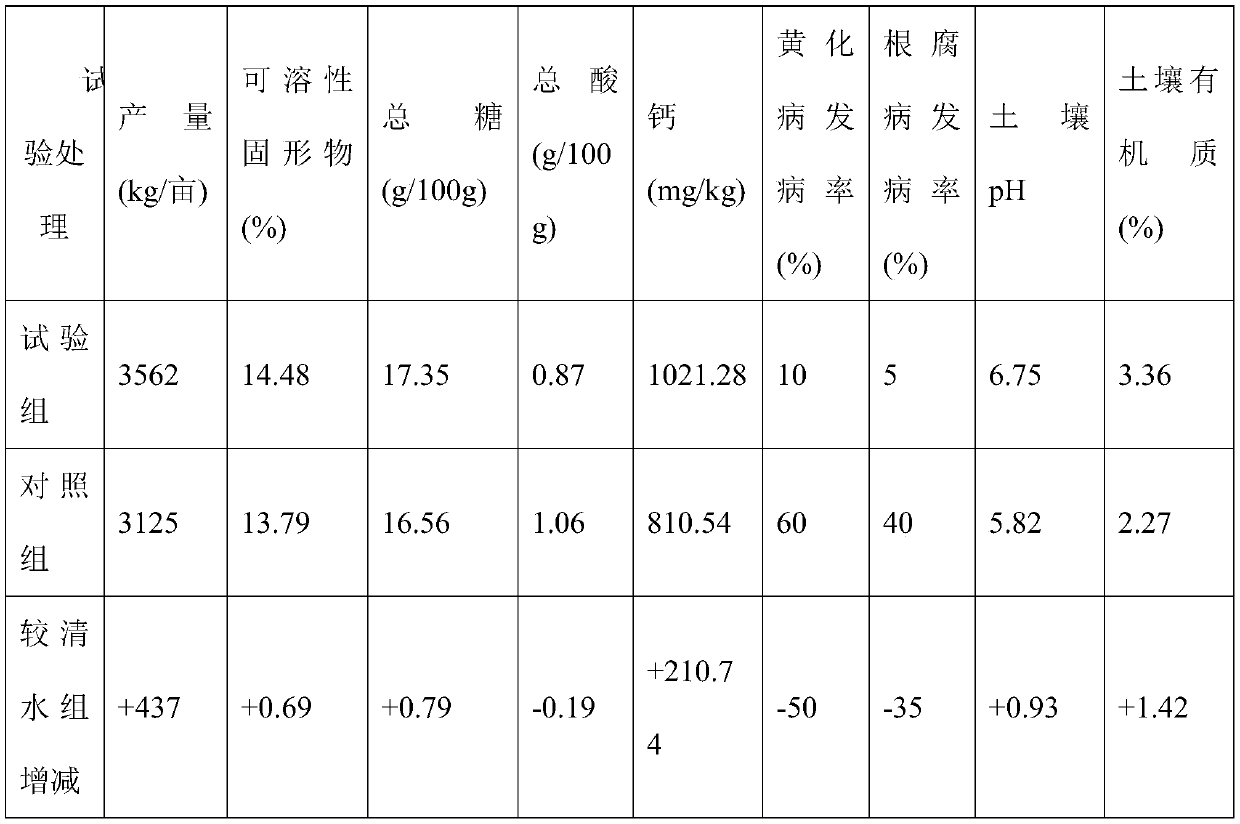

A technology for water-soluble fertilizers and shells, applied in the field of using shells to produce water-soluble fertilizers, can solve the problems of restricting the pace of high-quality utilization of shells and not maximizing the release, and achieve the goal of improving the quality of agricultural products, prolonging the shelf life, and improving the soil structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Mix shell powder, cassava residue, compound fermentation agent and water according to the weight ratio of 30:43.5:0.5:26, make strips or put them into fermentation tanks or fermentation containers for aerobic fermentation. The mass fraction is not lower than 5%, and the temperature of 55°C is maintained for at least 7 days during the fermentation process to obtain the fermentation product;

[0022] 2) After the fermentation is completed, add 300 kilograms of water to each ton of fermentation product and stir to dissolve for at least 30 minutes, then filter to obtain filter residue and filtrate, and the filtrate is the water-soluble fertilizer containing various medium and micronutrient elements of the present invention.

[0023] 3) The filter residue, fermentation product and functional bacteria are mixed according to the weight ratio of 60:39:1, which is the soil conditioner or biological fertilizer of the present invention.

Embodiment 2

[0025] 1) Mix shell powder, pineapple residue, compound fermentation agent and water according to the weight ratio of 50:29.5:0.5:20, make strips or put them into fermentation tanks or fermentation containers for aerobic fermentation. The mass fraction is not less than 5%, and the temperature of 50°C is maintained for at least 7 days during the fermentation process to obtain the fermentation product;

[0026] 2) After the fermentation is completed, add 300 kilograms of water to each ton of fermentation product and stir to dissolve for at least 30 minutes, then filter to obtain filter residue and filtrate, and the filtrate is the water-soluble fertilizer containing various medium and micronutrient elements of the present invention.

[0027] 3) The filter residue, fermentation product and functional bacteria are mixed according to the weight ratio of 50:49:1, which is the soil conditioner or biological fertilizer of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com