Spraying-free high-gloss piano black PETG/PC/APET alloy and preparation method thereof

A piano black and spray-free technology, which is applied in the field of spray-free high-gloss piano black PETG/PC/APET alloy and its preparation, can solve the problem that high-gloss materials cannot be used alone, and achieve excellent scratch-resistant Sassafras effect and good scratch resistance Effect, gloss improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of spray-free high-gloss piano black PETG / PC / APET alloy, the steps are as follows:

[0029] Step 1: Weigh the PETG resin of the formula, and dry it in a drying oven at a temperature of 65-70°C to remove moisture. The drying time is 6-8 hours;

[0030] Step 2: Weigh the amount of PC resin in the formula and dry it in a drying oven at a temperature of 100-120°C to remove moisture. The drying time is 8-10 hours;

[0031] Step 3: Weigh the APET resin, PET anti-scratch agent, compatibilizer and dried PETG resin and PC resin in the blender, stir and mix evenly to obtain mixture 1, and the stirring time is 5-8min;

[0032]Step 4: Weigh the organic black masterbatch, dispersant, flow modifier, glazing agent and composite antioxidant in the blender, mix evenly to make mixture 2; then add mixture 1 to mixture 2, Stir evenly to obtain mixture 3, wherein the stirring time of mixture 1 and mixture 2 is 5-8min;

[0033] Step 5: Add mixture three to a tw...

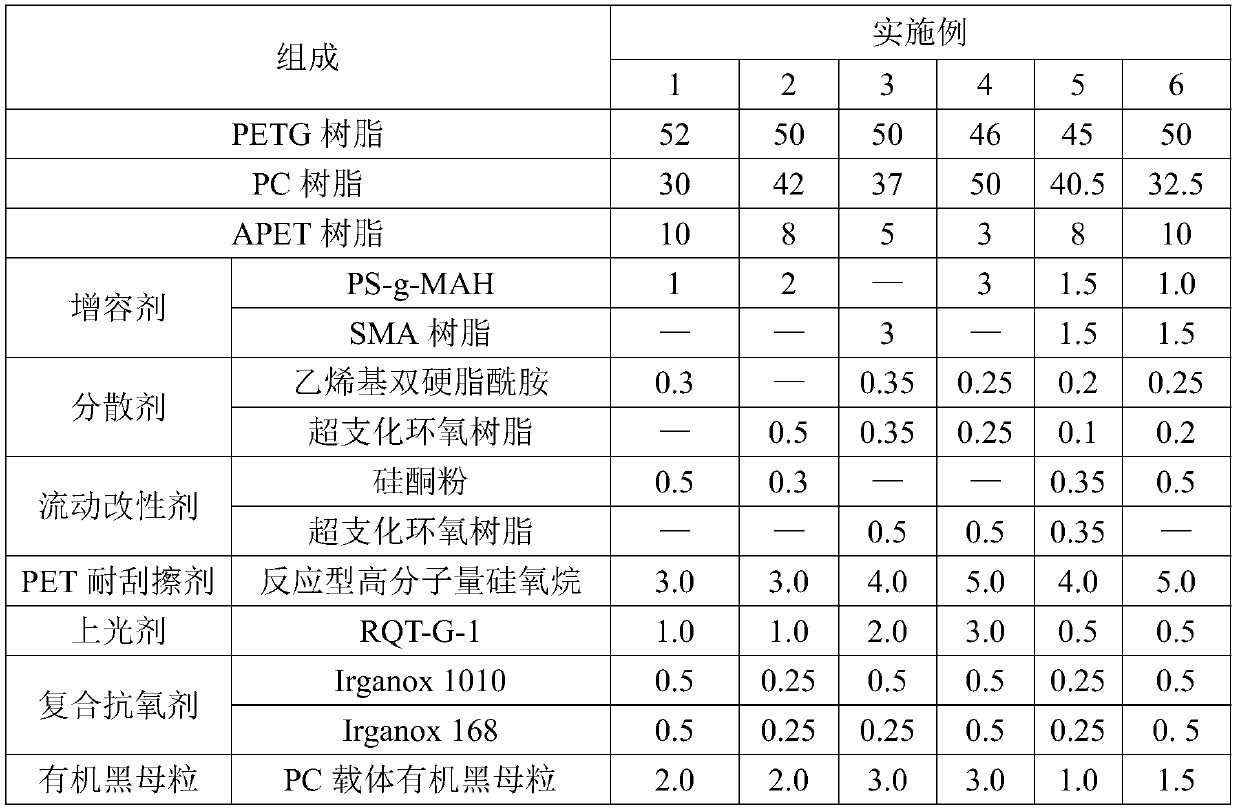

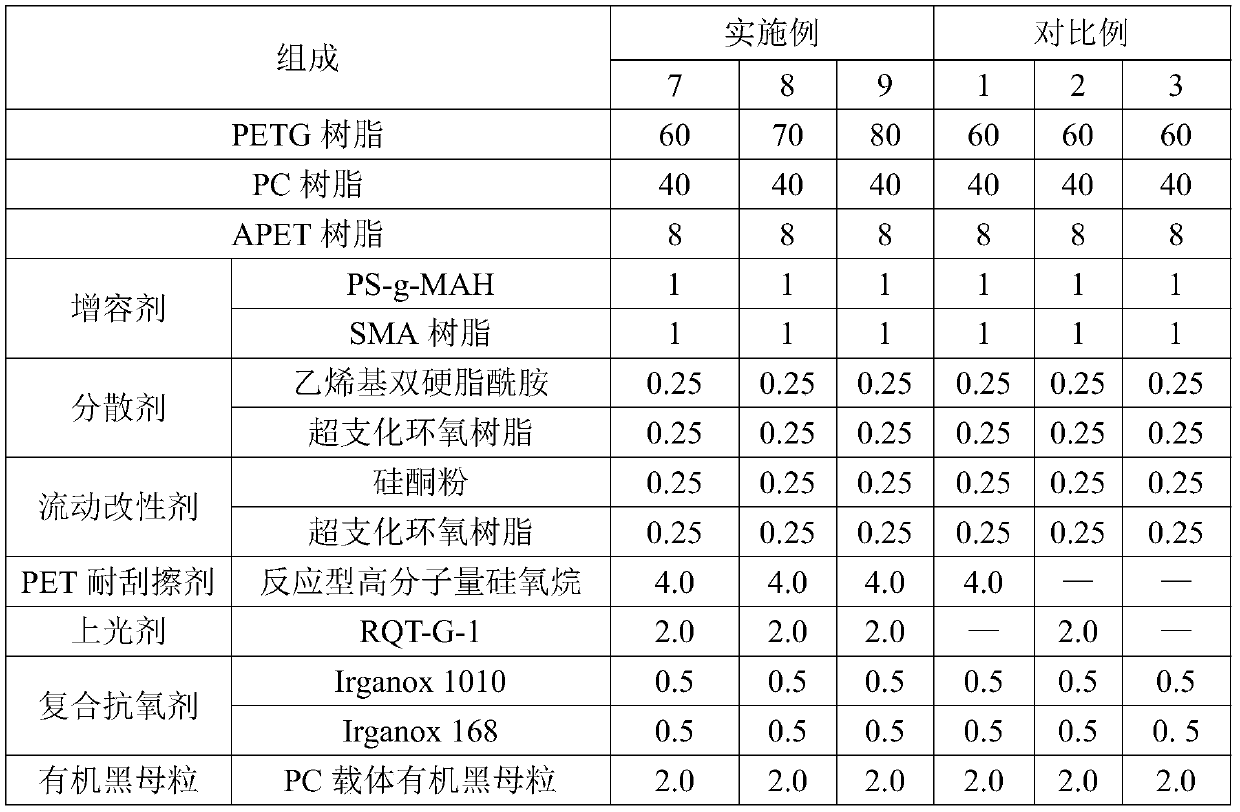

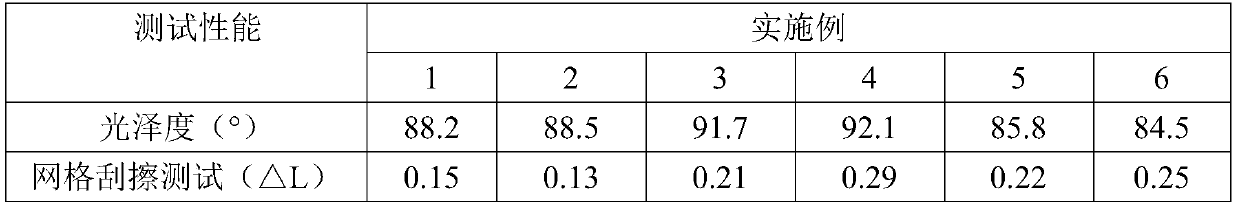

Embodiment 1-9

[0053] The preparation method of embodiment 1-9 is as follows:

[0054] Step 1: Weigh the PETG resin of the formula, and dry it in a drying oven at a temperature of 65-70°C to remove moisture. The drying time is 6-8 hours;

[0055] Step 2: Weigh the amount of PC resin in the formula and dry it in a drying oven at a temperature of 100-120°C to remove moisture. The drying time is 8-10 hours;

[0056] Step 3: Weigh the APET resin, PET anti-scratch agent, compatibilizer and dried PETG resin and PC resin in the blender, stir and mix evenly to obtain mixture 1, and the stirring time is 5-8min;

[0057] Step 4: Weigh the organic black masterbatch, dispersant, flow modifier, glazing agent and composite antioxidant in the blender, mix evenly to make mixture 2; then add mixture 1 to mixture 2, Stir evenly to obtain mixture 3, wherein the stirring time of mixture 1 and mixture 2 is 5-8min;

[0058] Step 5: Add mixture three to a twin-screw extruder for melt extrusion and granulation, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com