A mems flow sensor chip

A flow sensor and chip technology, applied in the measurement of flow/mass flow, liquid/fluid solid measurement, instruments, etc., can solve the problems of high technical difficulty, high production cost, short service life, etc., to optimize the arrangement structure, cost Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The present application can be implemented in many different forms, and is not limited to the implementation described in this embodiment. The following specific embodiments are provided for the purpose of facilitating a clearer and more thorough understanding of the disclosure of the present application, wherein words indicating orientation, such as up, down, left and right, are only for the positions of the illustrated structures in the corresponding drawings.

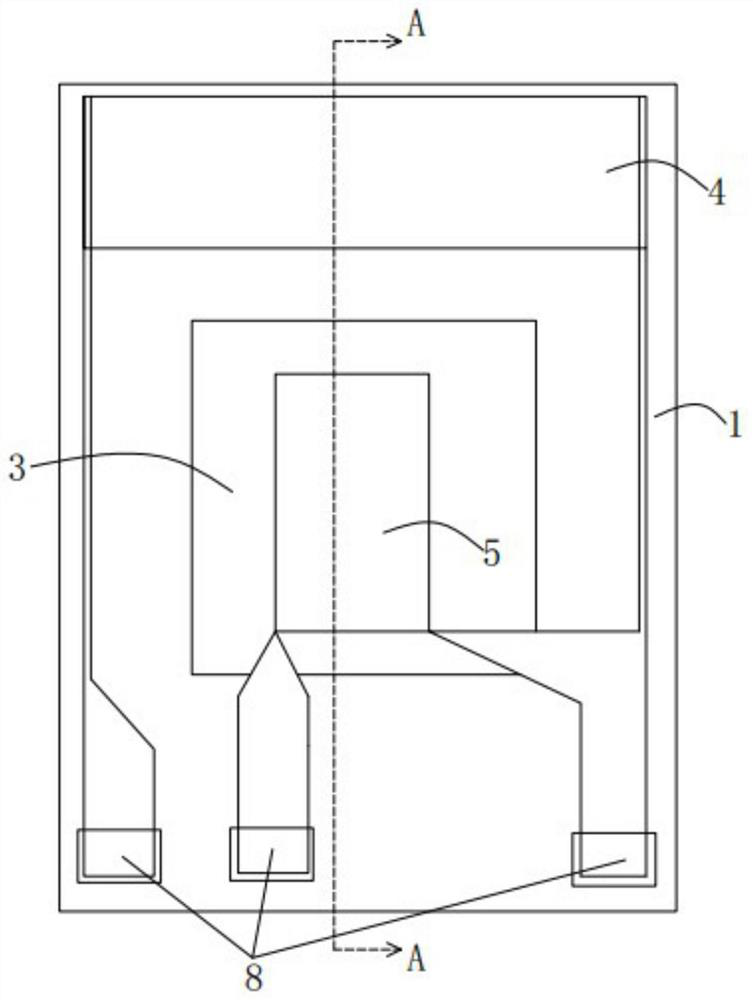

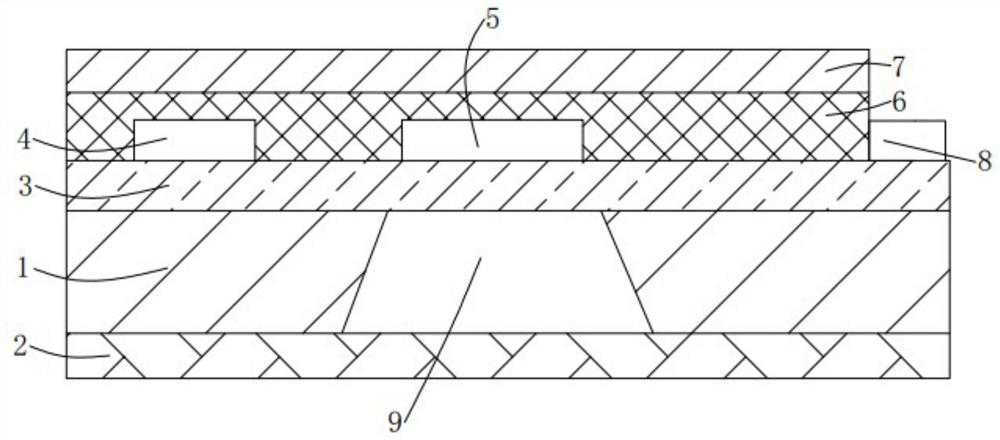

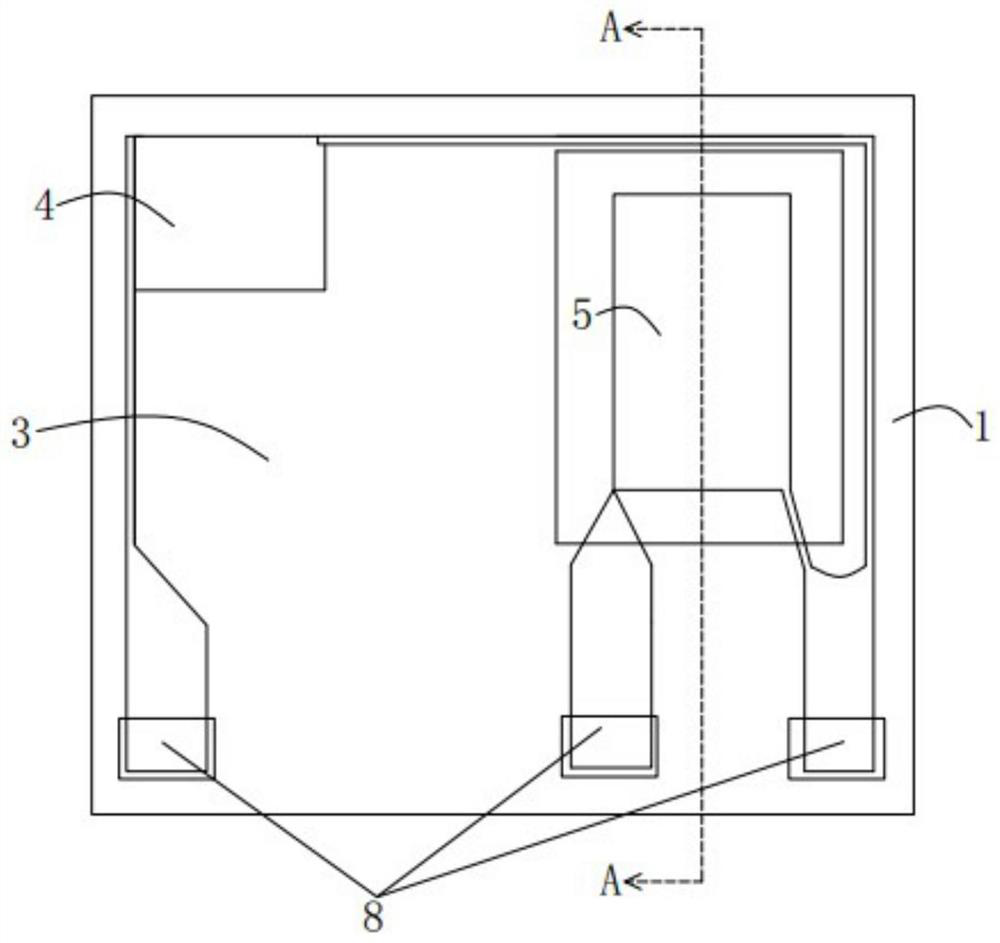

[0023] refer to Figure 1 to Figure 4 , the present invention provides a MEMS flow sensor chip, the MEMS flow sensor chip includes a substrate 1 having a cavity 9, a cavity protection layer 2 arranged under the substrate 1, and a resistance element support layer 3 stacked above the substrate 1. , the temperature sensing element 4 and the current measuring element 5 placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com