Performance and reliability joint simulation design method for aerospace mechanical and electrical product

A co-simulation technology for electromechanical products, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as poor combination of performance design and reliability design, difficulty in meeting the design cycle, hidden dangers in reliability, etc., and achieve improvement The effect of major basic capabilities, shortening the development cycle, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0164] A typical product selects the electromechanical product solar wing drive mechanism on a certain type of remote sensing satellite public platform as the case object. According to the product design requirements, it has been in orbit for 8 years, and the reliability index is 0.995.

[0165] (1) The random vibration, temperature cycle and energizing current are sorted out as the typical stress types of the solar wing drive mechanism.

[0166] (2) It is analyzed that the movement jamming and thermal deformation of the rotating parts, the fracture of structural parts, and the short circuit and short circuit of the circuit are the main failure modes and failure mechanisms of the solar wing drive mechanism.

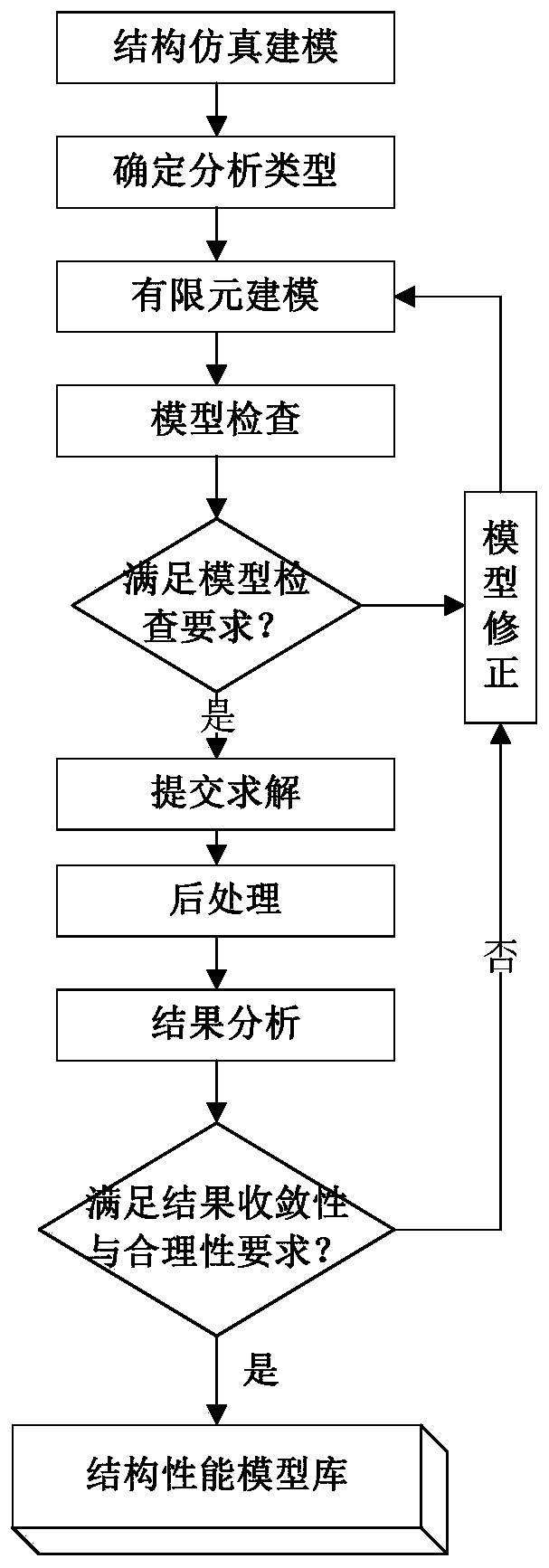

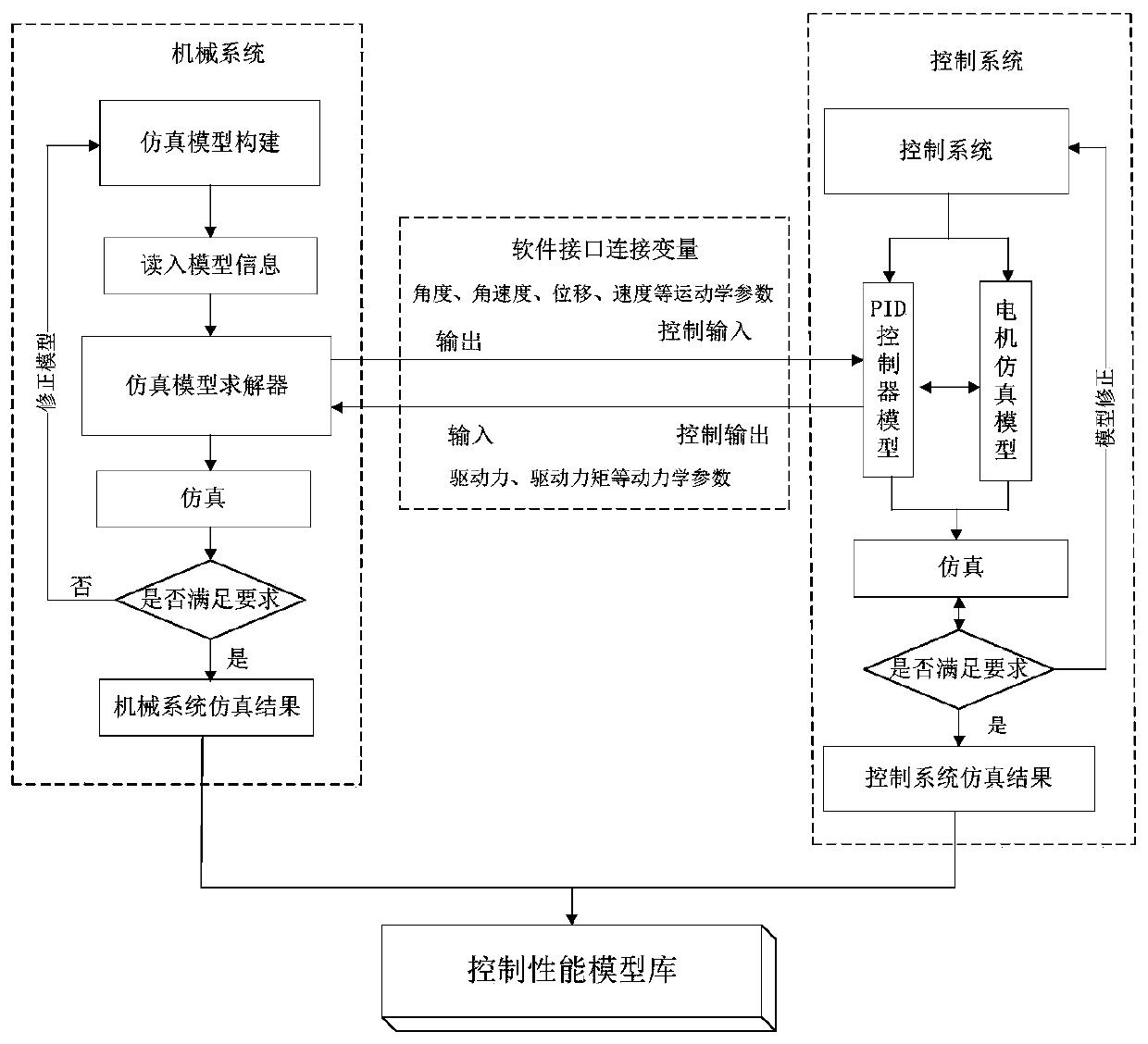

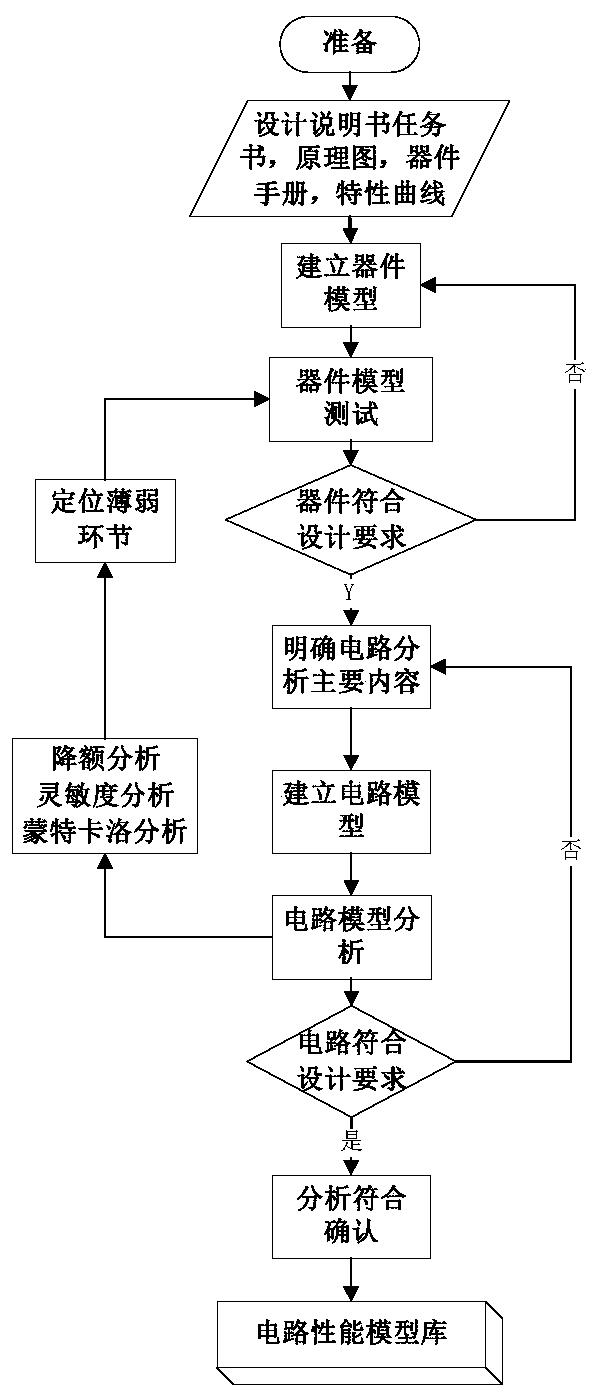

[0167] (3) The structural simulation model, control simulation model and circuit simulation model of the solar wing drive mechanism are constructed, and the model reaches more than 90% after verification. .

[0168] (4) After the sensitivity analysis of the design parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com