Fan-shaped heat dissipation cable and fan-shaped heat dissipation optical cable

A fan-shaped and cable technology, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of reduced tear resistance, poor cable heat dissipation, and low efficiency, and achieve light weight, excellent heat dissipation, and tear resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

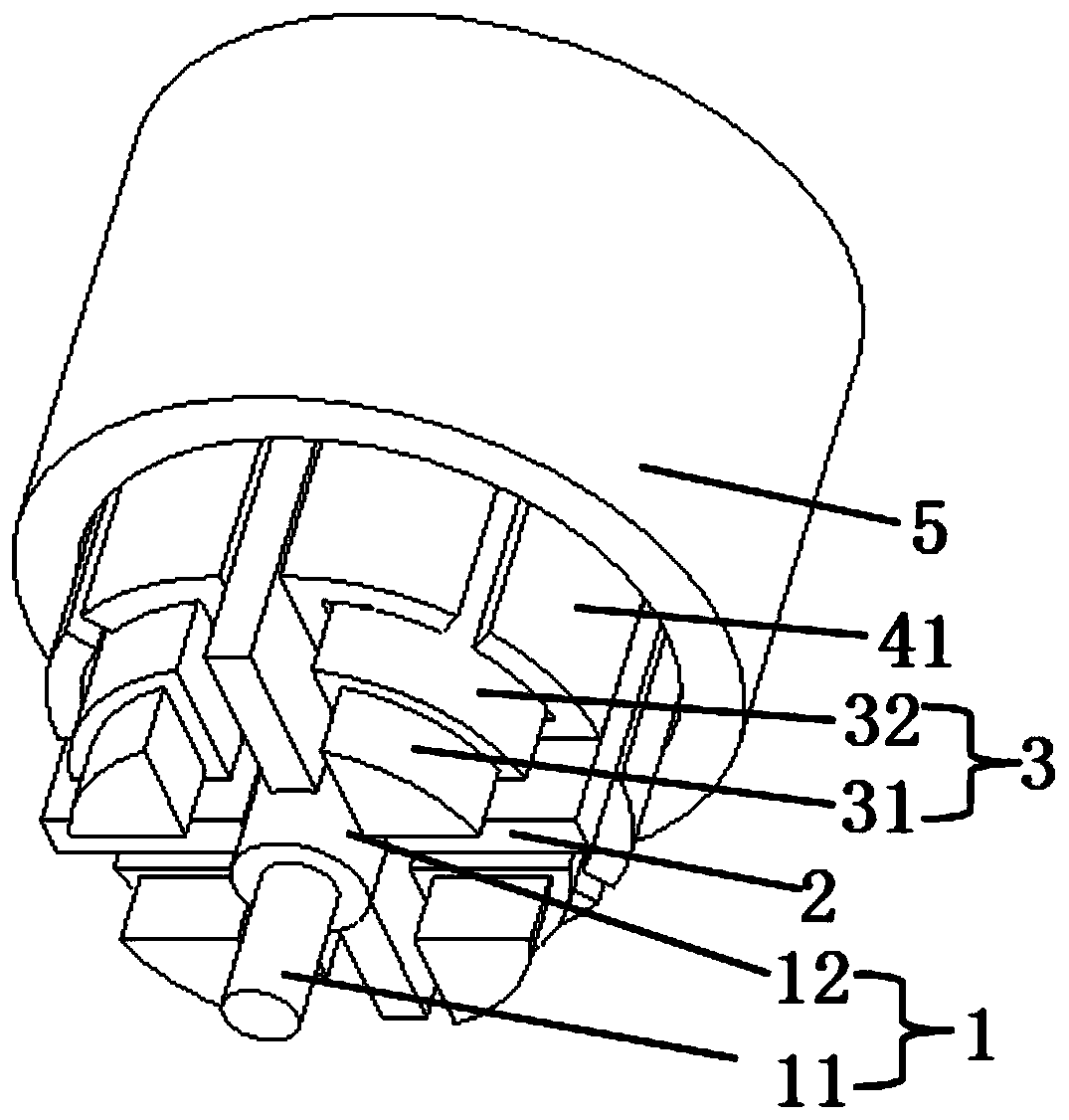

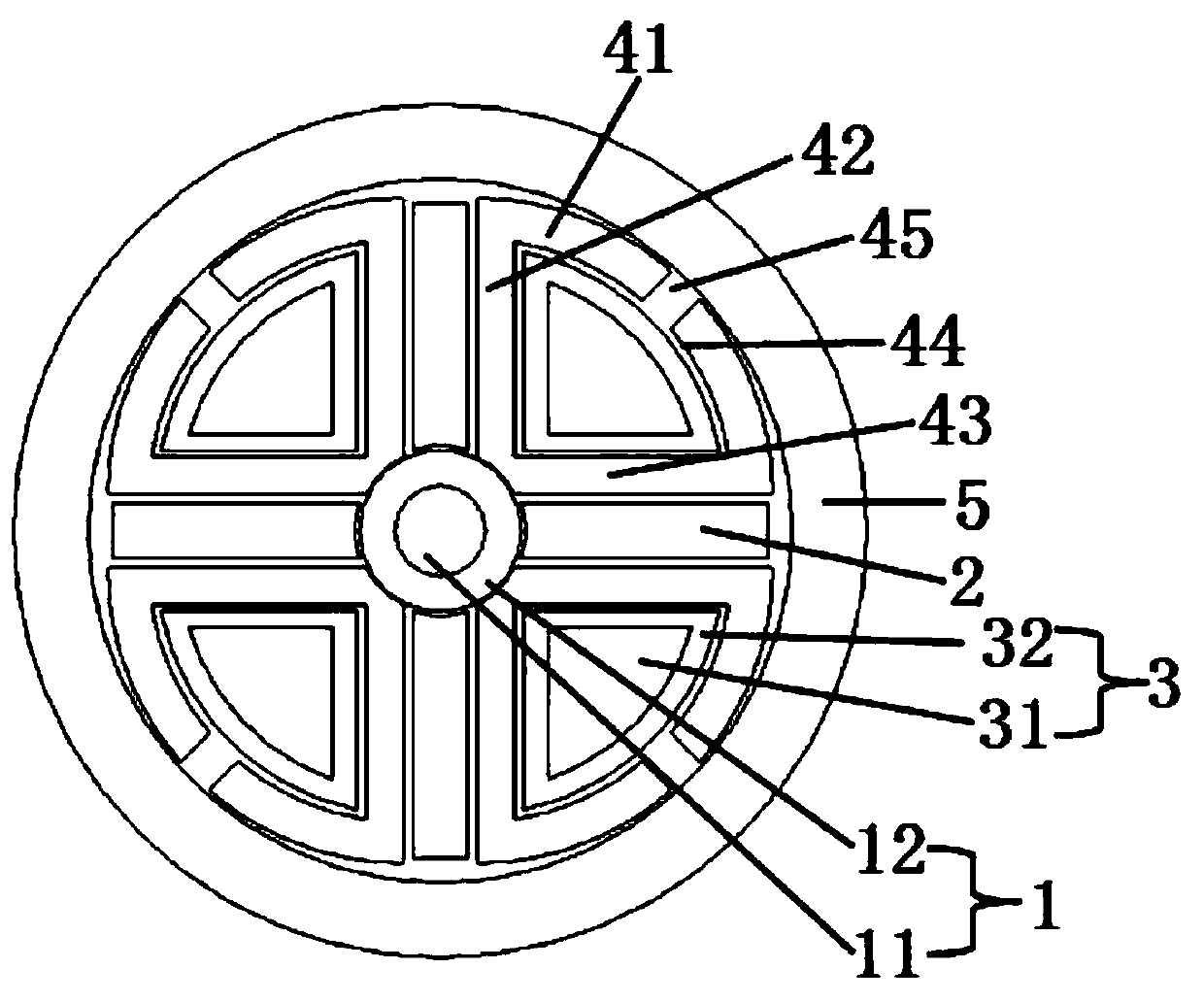

[0038] please see figure 1 and figure 2 , a fan-shaped heat dissipation cable, has a strengthening unit 1 located in the center, four power transmission bodies located outside the strengthening unit and evenly distributed, and an outer sheath 5 covering the power transmission body. The pad layer 12 coated outside the reinforcement is composed of an insulator and an electric unit 3 located in the insulator; it is characterized in that the cross section of the insulator is fan-shaped, and the insulator is composed of an arc cylinder 41, a first protection body 42, the second protection body 43 surrounds, the first protection body and the second protection body are cuboid shape, and the arc cylinder is the arc ring cylinder shape, and one end of the first protection body is connected with one end of the second protection body , the other end of the first protection body is connected to one end of the arc cylinder, the other end of the second protection body is connected to the ...

Embodiment 2

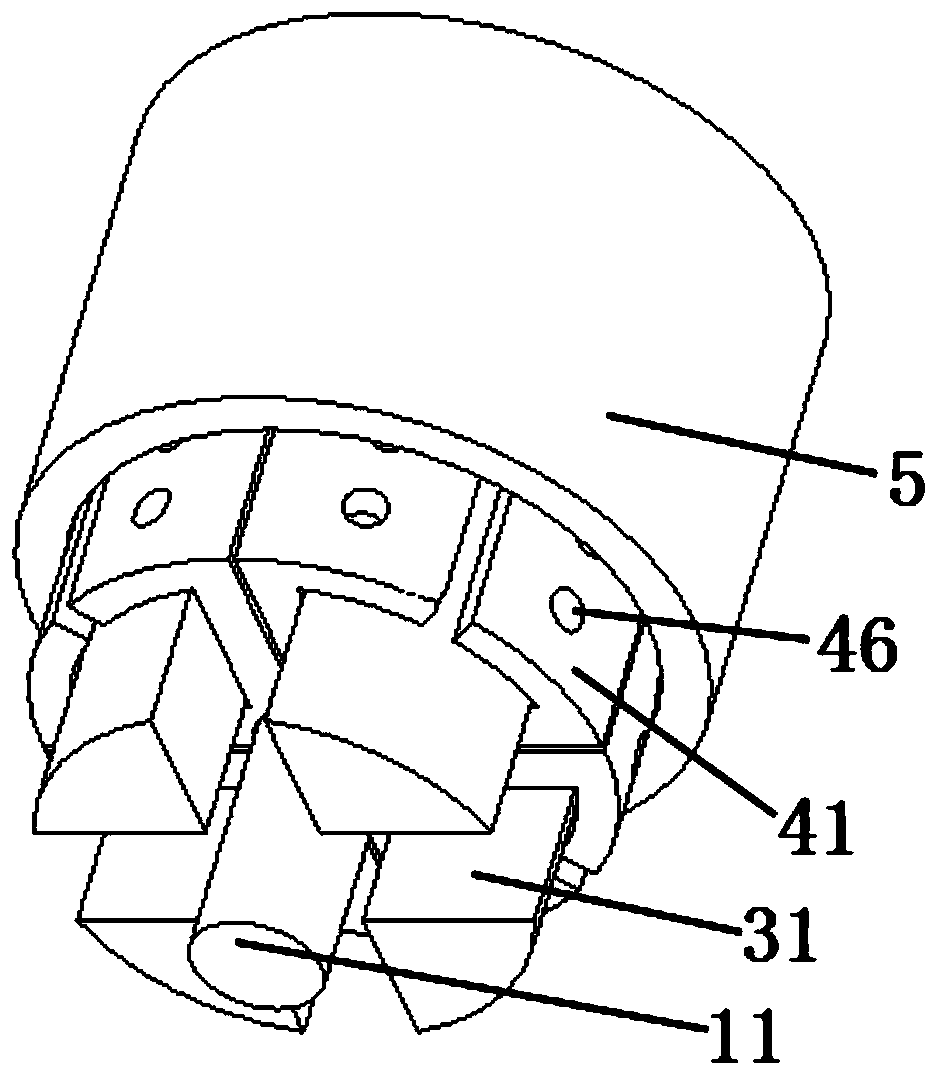

[0040] please see image 3 and Figure 4 , and refer to figure 1 and figure 2 , a fan-shaped heat dissipation cable, has a strengthening unit located in the center, four power transmission bodies located outside the strengthening unit and evenly distributed, an outer sheath 5 covering the power transmission body, the strengthening unit is a reinforcement 11, each power transmission The body is composed of an insulator and an electric unit 3 located in the insulator; it is characterized in that the cross section of the insulator is fan-shaped, and the insulator is surrounded by an arc cylinder 41, a first protection body 42, and a second protection body 43. The first protection body and The second protection body is in the shape of a cuboid, the arc cylinder is in the shape of an arc ring cylinder, one end of the first protection body is connected to one end of the second protection body, and the other end of the first protection body is connected to one end of the arc cylin...

Embodiment 3

[0043] please see Figure 5 and Figure 6 , and refer to Figure 1 to Figure 4, a fan-shaped heat dissipation cable, has a strengthening unit located in the center, four power transmission bodies located outside the strengthening unit and evenly distributed, an outer sheath 5 covering the power transmission body, the strengthening unit is a reinforcement 11, each power transmission The body is composed of an insulator and an electric unit 3 located in the insulator; it is characterized in that the cross section of the insulator is fan-shaped, and the insulator is surrounded by an arc cylinder 41, a first protection body 42, and a second protection body 43. The first protection body and The second protection body is in the shape of a cuboid, the arc cylinder is in the shape of an arc ring cylinder, one end of the first protection body is connected to one end of the second protection body, and the other end of the first protection body is connected to one end of the arc cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com