Electrostatic discharge method and device for electrostatic chuck

An electrostatic discharge device and electrostatic chuck technology, which are applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of difficult to completely discharge static electricity, wafer fragmentation, machine shutdown, etc., to reduce alarms and prolong service life. , the effect of reducing expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

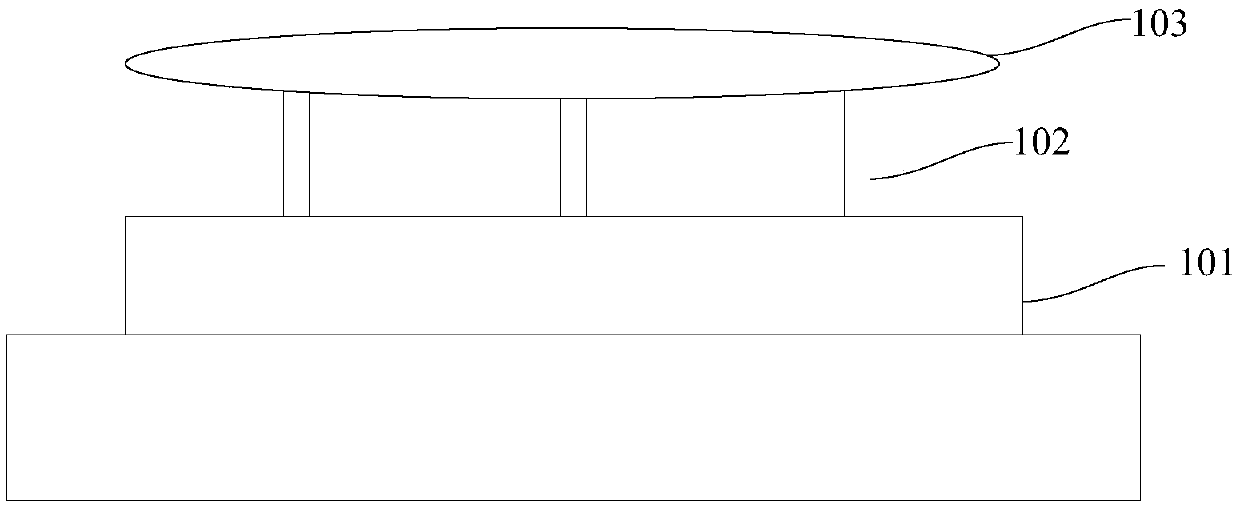

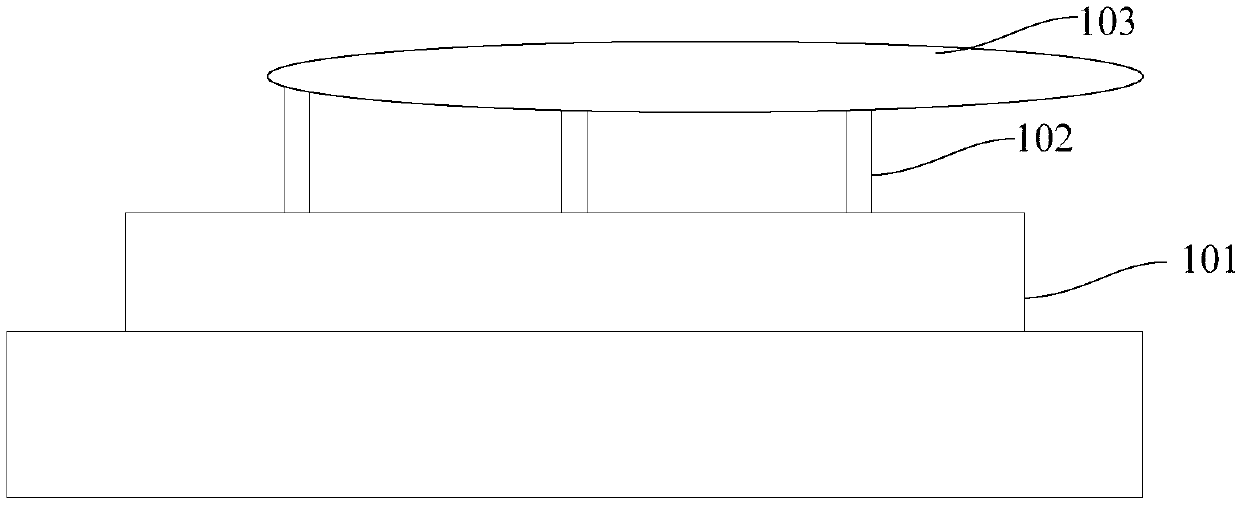

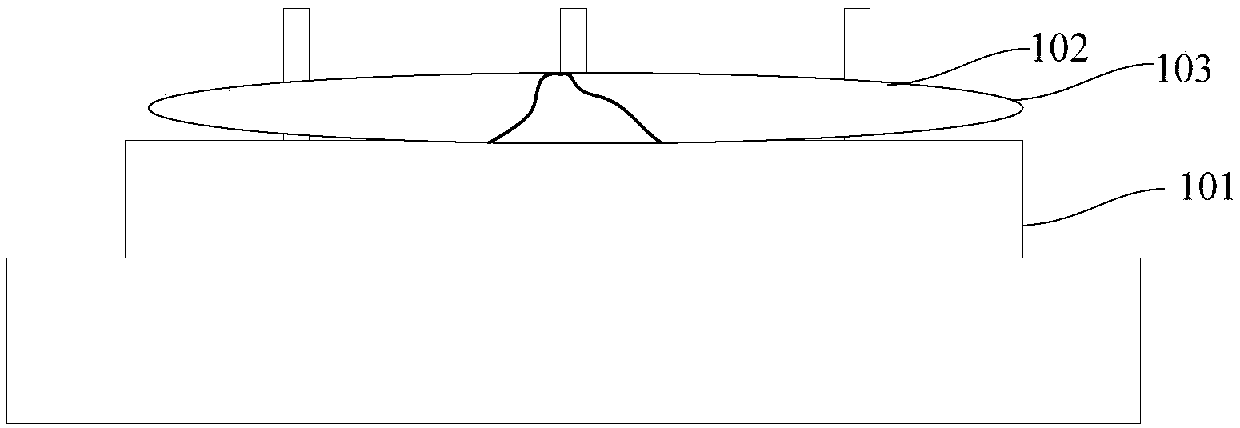

[0044] This embodiment provides an electrostatic discharge method for an electrostatic chuck. The electrostatic chuck 200 includes a chuck 201 and a wafer pin 202. The electrostatic chuck 200 is provided with a driving device. The wafer pin 202 can be driven by the driving device. The up and down reciprocating movement pushes up the wafer 203 from the carrying surface of the chuck 201 or places the wafer 203 on the carrying surface of the chuck 201. The lifting position of the wafer pin 202 in this embodiment includes a pre-desorption position H1 and a target position H2. The target position H2 is higher than the pre-desorption position H1, and the height of the pre-desorption position H1 is between The target position H2 is between 1 / 50 and 1 / 2 of the height, the pre-desorption position H1 is a position where the adsorption force between the wafer 203 and the electrostatic chuck 200 is basically overcome, and the target position H2 may be a position where the wafer is operated...

Embodiment 2

[0061] Such as Figure 8 As shown, this embodiment provides an electrostatic discharge device of the electrostatic chuck 200, and the electrostatic discharge device includes an electrostatic chuck 200, a power supply 204, and a processing unit 205.

[0062] The electrostatic chuck 200 is used to suck the wafer 203, and the electrostatic chuck 200 is provided with a wafer pin 202, and the wafer pin 202 is used to lift the wafer 203. The electrostatic chuck 200 includes a chuck 201 and a wafer pin 202. The electrostatic chuck 200 is provided with a driving device (not shown). The wafer pin 202 can reciprocate up and down under the drive of the driving device, so that the wafer The circle 203 is raised from the carrying surface of the chuck 201 or the wafer 203 is placed on the carrying surface of the chuck 201. The lifting position of the wafer pin 202 in this embodiment includes a pre-desorption position H1 and a target position H2. The target position H2 is higher than the pre-de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com