Burner for a fuel cell system with two reaction chambers

A technology of fuel cell system and burner, which is applied to the use of such burner, fuel cell system, burner of SOFC system, and the field of operating fuel cell system, which can solve unknown problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

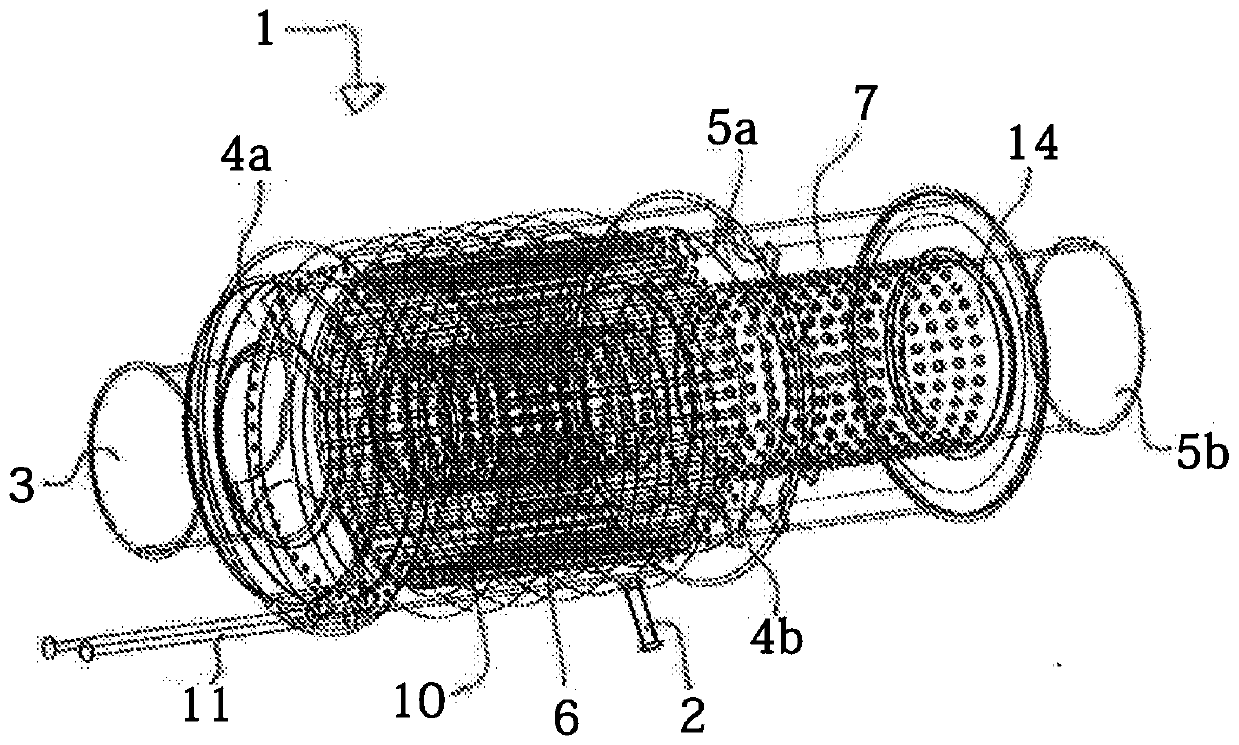

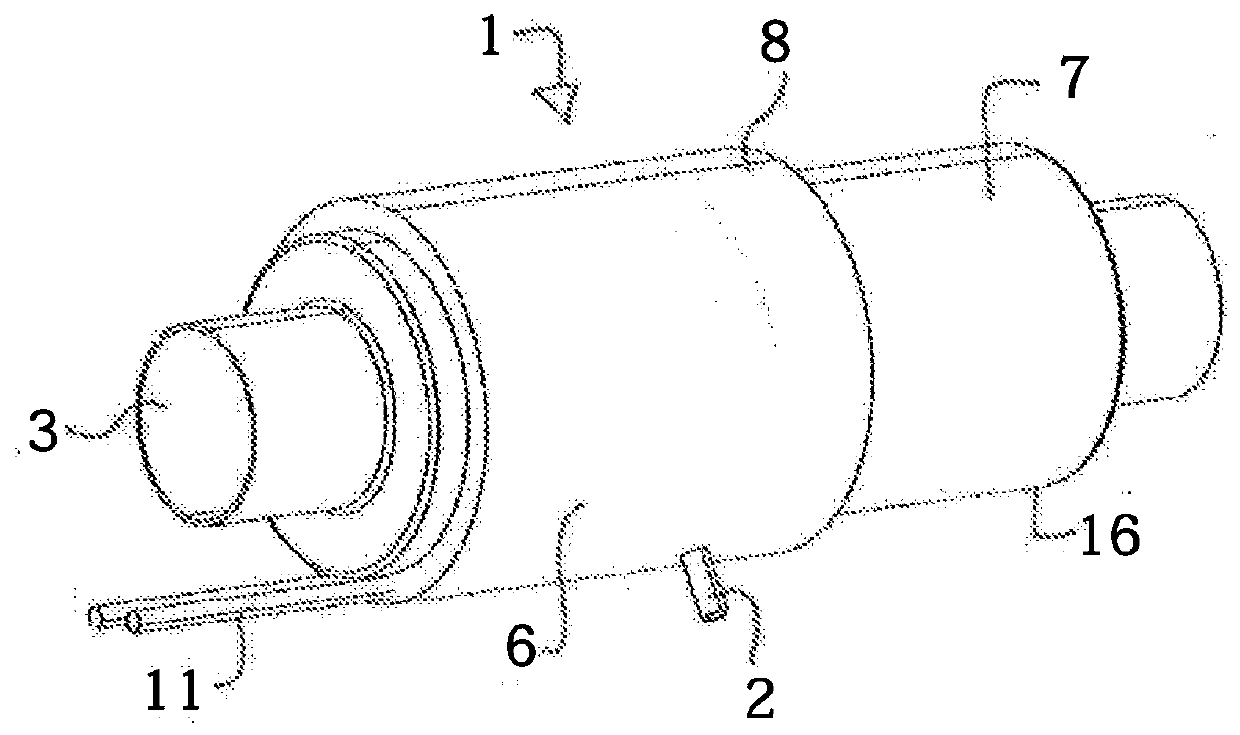

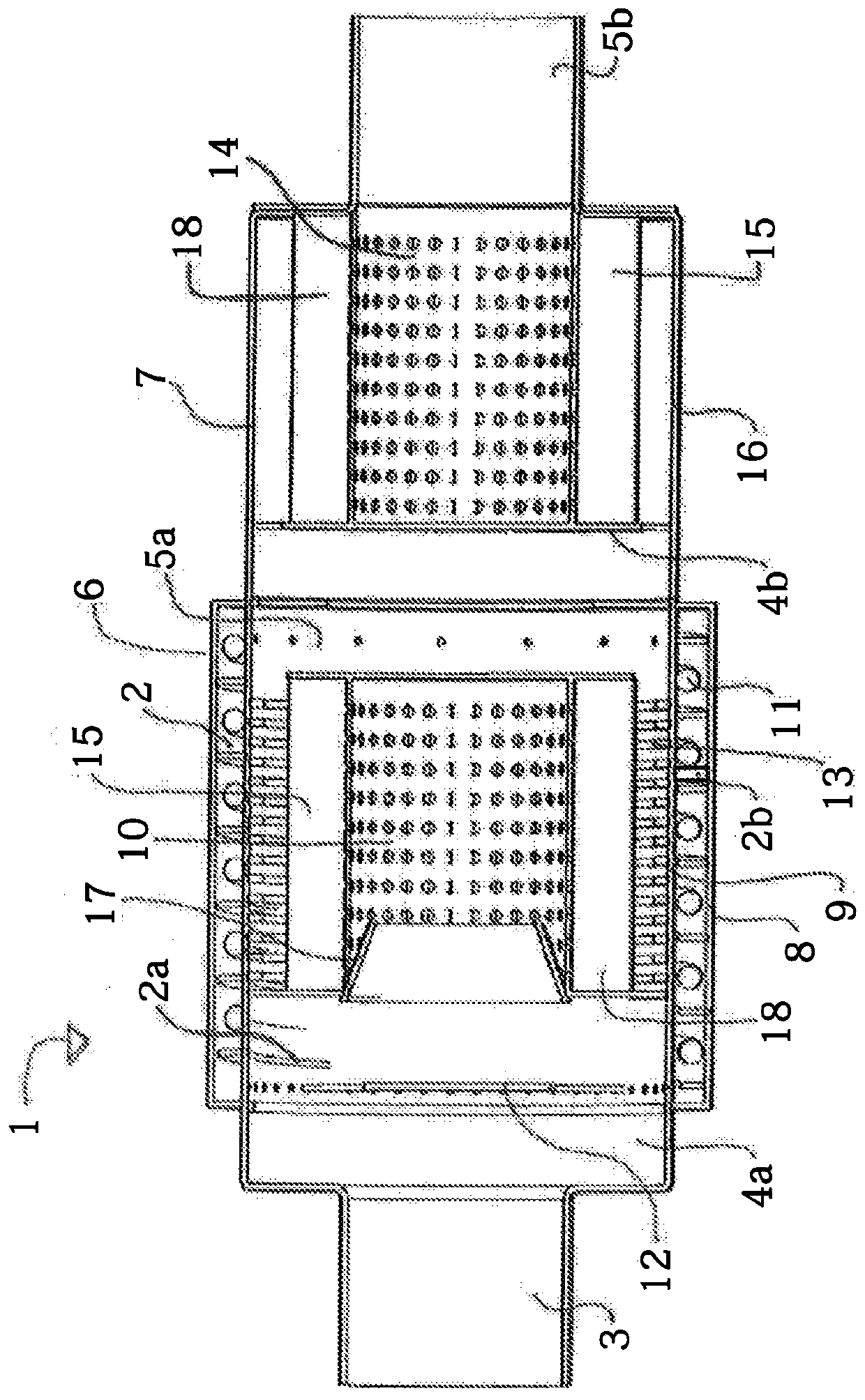

[0055] figure 1 and figure 2 A burner 1 for a fuel cell system 100 according to the invention is shown. It comprises two reaction chambers 6 , 7 which are arranged one behind the other in the direction of flow. Each reaction chamber 6, 7 has a chamber inlet 4a, 4b and a chamber outlet 5a, 5b, respectively. The burner 1 also has a first working fluid guide part 2 and a second working fluid guide part 3, wherein the first working fluid guide part 2 is designed for guiding the first working fluid, and the second working fluid guide part 3 is designed for A second working fluid is channeled. Within the scope of the invention, an ethanol-water mixture is preferably used as the first working fluid and air as the second working fluid. The first working fluid guide 2 here comprises a first section 2a and a second section 2b.

[0056] Such as figure 1 and figure 2 As shown, the first reaction chamber 6 and the second reaction chamber 7 of the burner 1 are both in the form of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com