Bionic crushing device with adjustable particle sizes of humid ore

A crushing device and bionic technology, applied in grain processing and other directions, can solve the problems of attapulgite, rock and soil crushing that cannot meet the strong viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

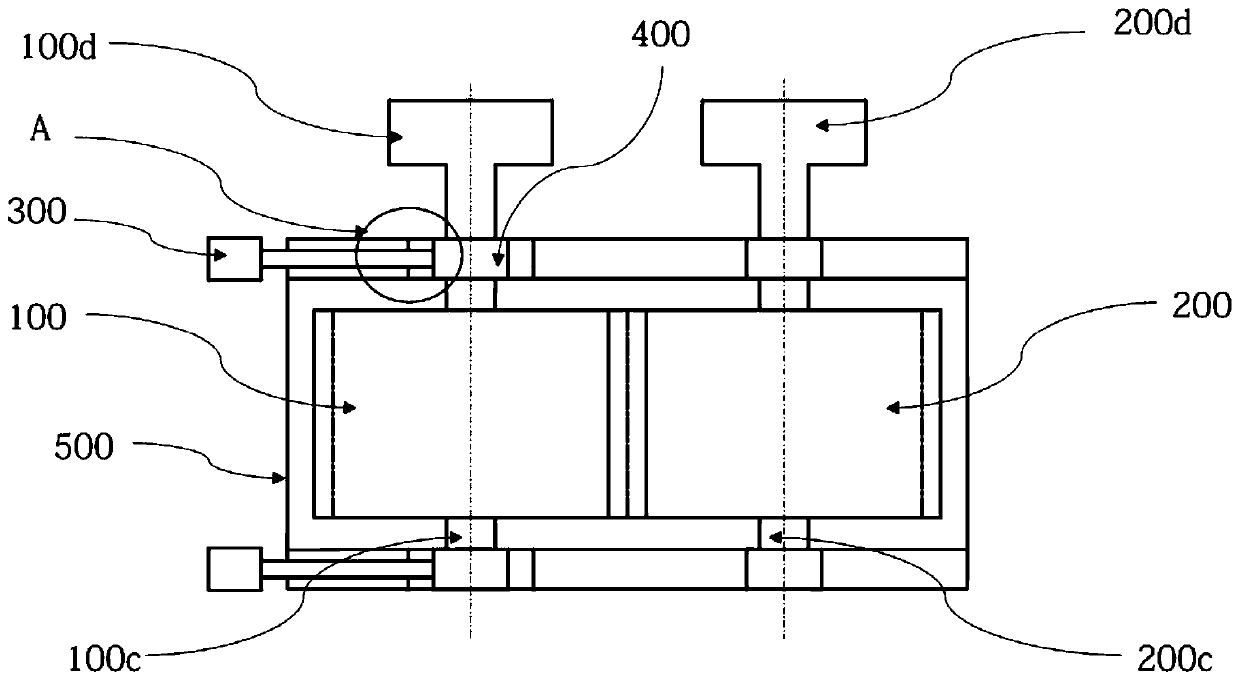

[0033] The invention provides a bionic crushing device with adjustable particle size for tidal ore, which is a bionic-based device capable of crushing viscous solid minerals into solid powders with different particle sizes. Such as figure 1 As shown, the crushing device includes a first crushing roller 100 , a second crushing roller 200 and a particle size adjustment mechanism 300 .

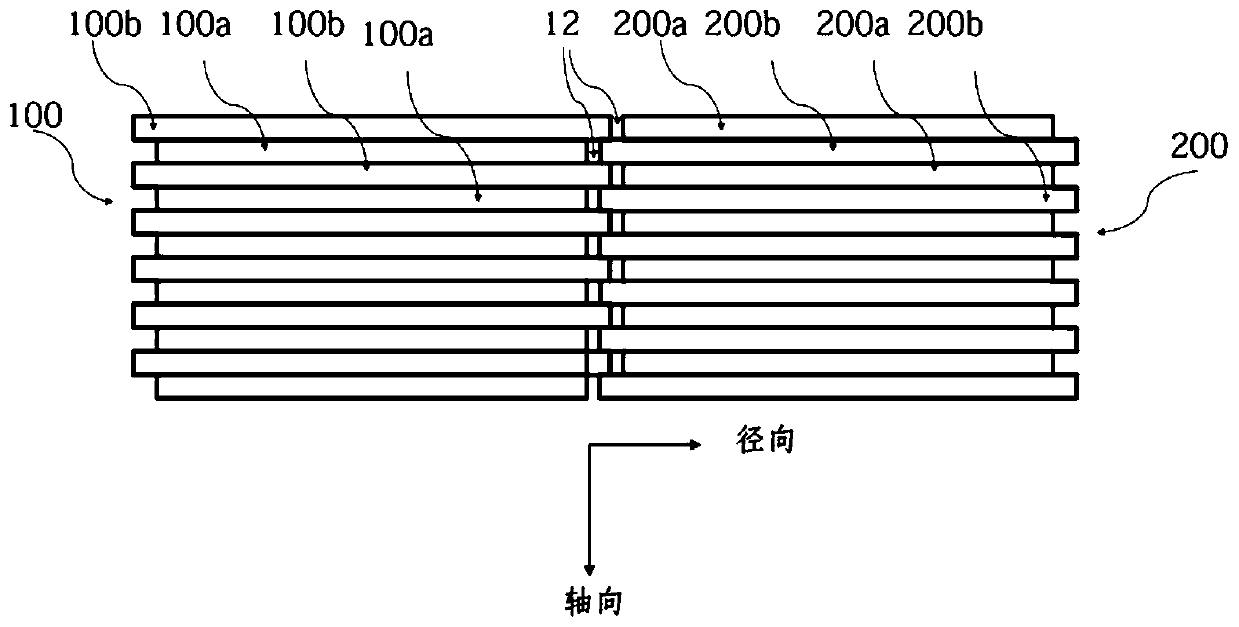

[0034] The first crushing roller 100 is arranged with a first crushing groove 100a and a first crushing grain 100b along its axial direction. And the first crushing groove 100a and the first crushing grain 100b are spaced apart sequentially, such as figure 2 shown. In the same manner, the second crushing roller 200 is arranged with a second crushing groove 200a and a second crushing grain 200b along its axial direction. Moreover, the second crushing groove 200a and the second crushing grain 200b are sequentially spaced apart. During installation, such as figure 2 As shown, the first crushi...

Embodiment 2

[0044] This embodiment may be a further improvement and / or supplement to Embodiment 1, and repeated content will not be repeated here. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

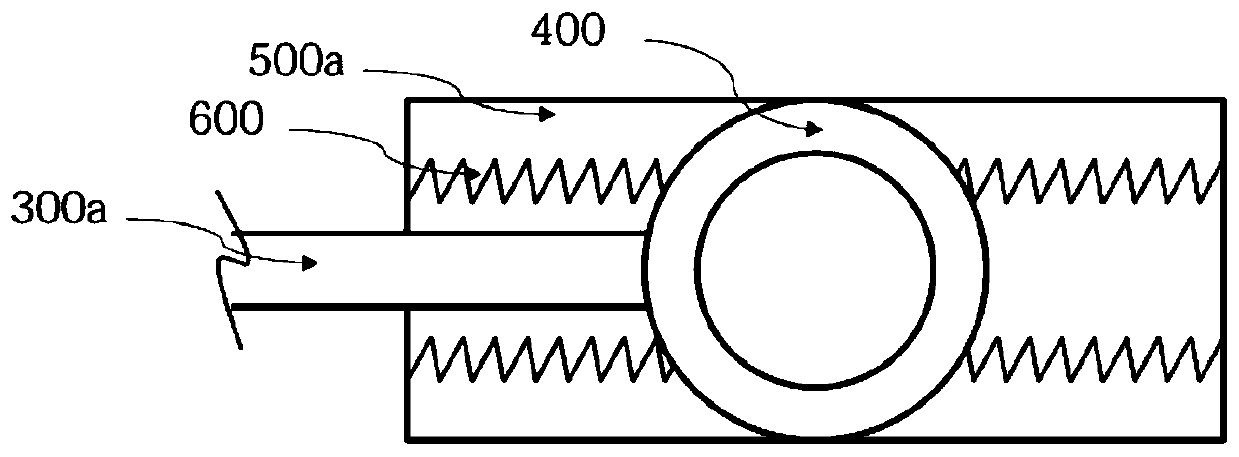

[0045] In this embodiment, the particle size adjustment mechanism 300 acts on the second support mechanism matched with the second transmission shaft of the second crushing roller 200 in the same manner as the first support mechanism acting on the first transmission shaft of the first crushing roller 100 on, used to adjust the radial position of the second crushing mixer 200.

[0046] Preferably, both the first crushing roll 100 and the second crushing roll 200 are configured with a particle size adjusting structure 300 . However, in terms of equipment cost, it is a better choice that the particle size adjusting mechanism 300 only acts on the supporting mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com