A method for preparing layered metal composites by multilayer-cumulative stack rolling

A composite material and layered metal technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of slow thinning efficiency of layer thickness, instability of layer structure, etc., and achieve the suppression of microcracks, etc. Accumulation of defects, promotion success rate, effect of ply refinement efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

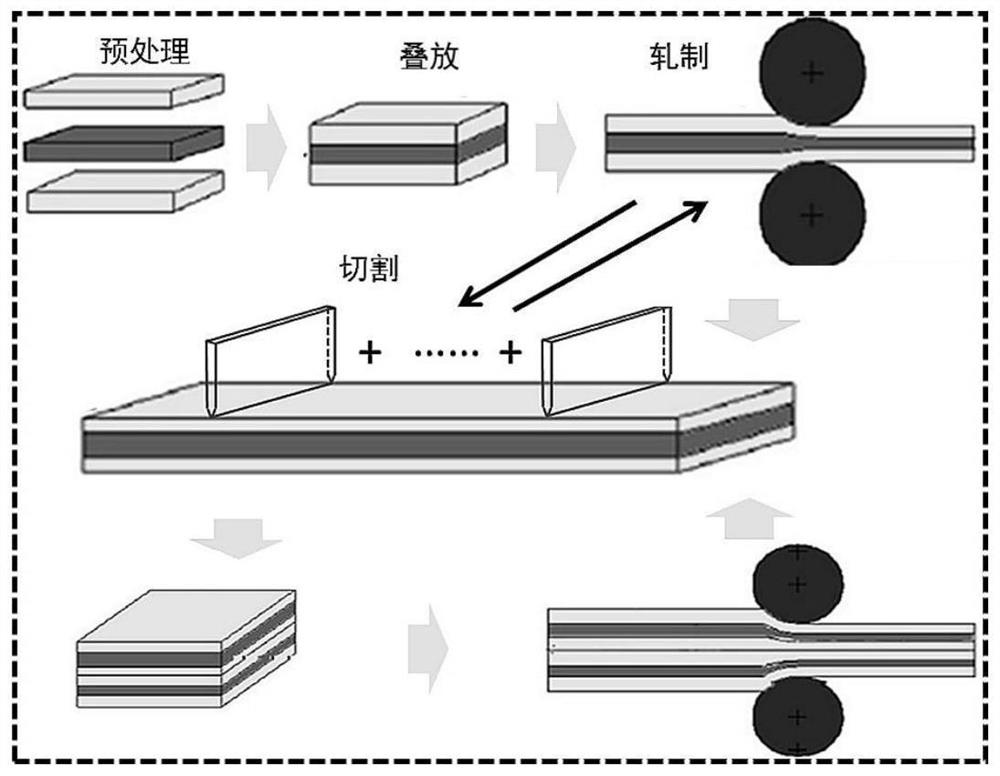

[0031] Example 1: Preparation of silver / copper (volume ratio 1:1, reduction 75%) layered metal composite material by multilayer-cumulative stack rolling

[0032] (1) Silver flakes with a purity of 99.99% and copper flakes with a purity of 99.95% are used. Cut the silver sheet and copper sheet into sizes of 30mm (width)×30mm (length)×0.5mm (thickness) and 30mm (width)×30mm (length)×1mm (thickness);

[0033] (2) carrying out the annealing treatment at 400° C. for 2 h with the above-mentioned cut silver and copper flakes;

[0034] (3) The silver and copper sheets after the annealing are polished by surface sandpaper and cleaned with alcohol to remove the oil stain on the surface of the metal sheet;

[0035] (4) Stacking in the order of copper / silver / copper, before stacking, polish the contact surfaces between the thin plates with a steel brush to remove the oxide layer on the metal surface to promote the bonding between the interfaces;

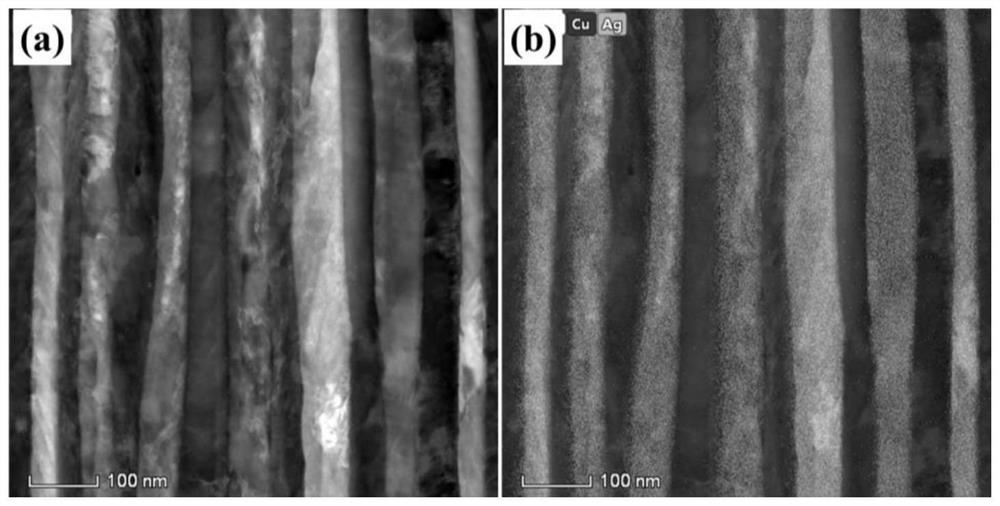

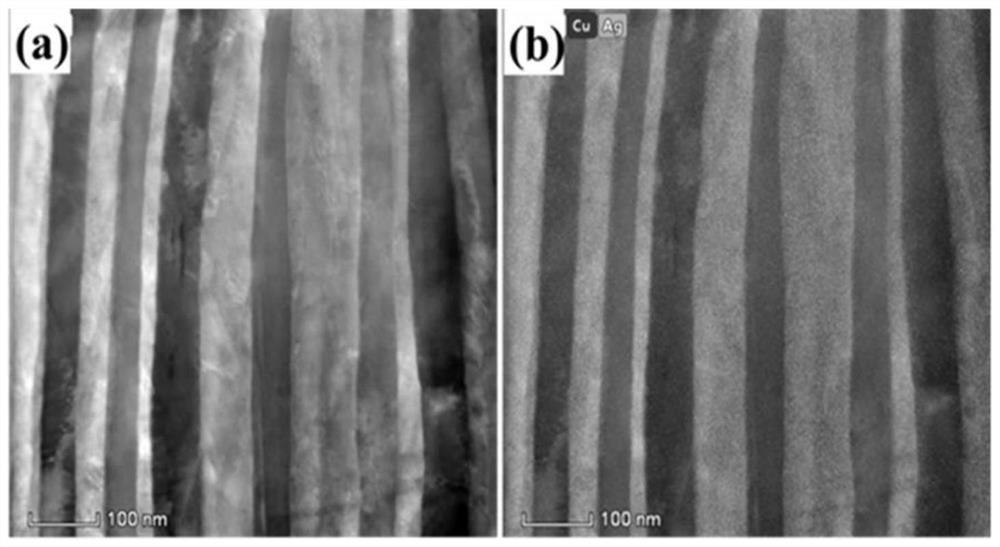

[0036] (5) Roll the above-mentioned stac...

example 2

[0040] Example 2: Preparation of silver / copper (volume ratio 2:1, reduction 75%) layered metal composite material by multilayer-cumulative stack rolling

[0041] (1) Silver flakes with a purity of 99.99% and copper flakes with a purity of 99.95% are used. Cut the silver sheet and copper sheet into sizes of 30mm (width) × 30mm (length) × 1mm (thickness) and 30mm (width) × 30mm (length) × 0.25mm (thickness);

[0042] (2) carrying out the annealing treatment at 400° C. for 2 h with the above-mentioned cut silver and copper flakes;

[0043] (3) The silver and copper sheets after the annealing are polished by surface sandpaper and cleaned with alcohol to remove the oil stain on the surface of the metal sheet;

[0044] (4) Stacking in the order of copper / silver / copper, before stacking, polish the contact surfaces between the thin plates with a steel brush to remove the oxide layer on the metal surface to promote the bonding between the interfaces;

[0045] (5) Roll the above-menti...

example 3

[0049] Example 3: Preparation of silver / copper (volume ratio 1:1, reduction 80%) layered metal composite material by multilayer-cumulative stack rolling

[0050] (1) Silver flakes with a purity of 99.99% and copper flakes with a purity of 99.95% are used. Cut the silver sheet and copper sheet into sizes of 30mm (width)×30mm (length)×1mm (thickness) and 30mm (width)×30mm (length)×0.5mm (thickness);

[0051] (2) carrying out the annealing treatment at 400° C. for 2 h with the above-mentioned cut silver and copper flakes;

[0052] (3) The silver and copper sheets after the annealing are polished by surface sandpaper and cleaned with alcohol to remove the oil stain on the surface of the metal sheet;

[0053] (4) Stacking in the order of copper / silver / copper, before stacking, polish the contact surfaces between the thin plates with a steel brush to remove the oxide layer on the metal surface to promote the bonding between the interfaces;

[0054] (5) Roll the above-mentioned stac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com