Special-shaped thin-walled part fastening mechanism

A technology for thin-walled parts and fastening mechanisms, which is applied in the field of fastening mechanisms for special-shaped thin-walled parts. It can solve problems such as difficult parts processing and mass production, high surface finish requirements, clamping tool clamping, etc., and achieve positioning accuracy. High, low labor intensity, stable push and pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

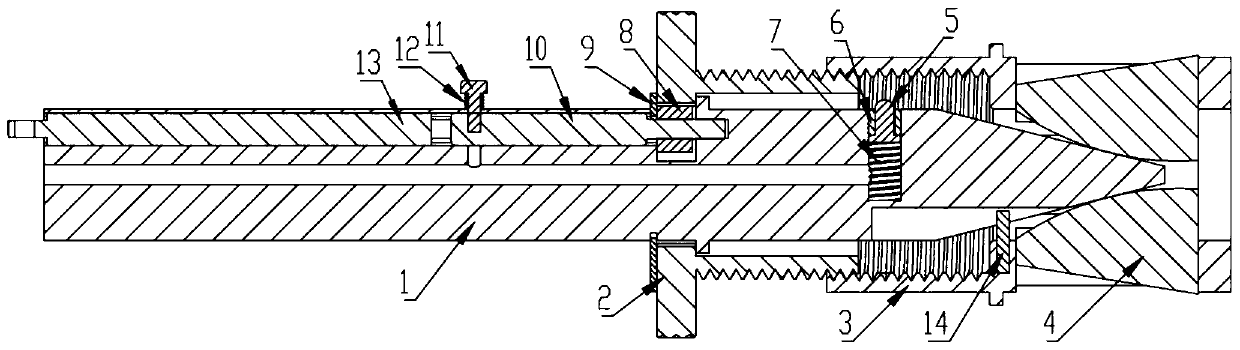

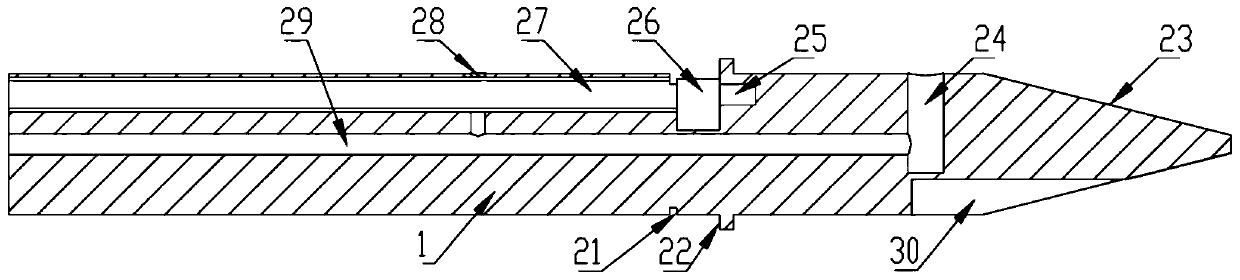

[0038] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

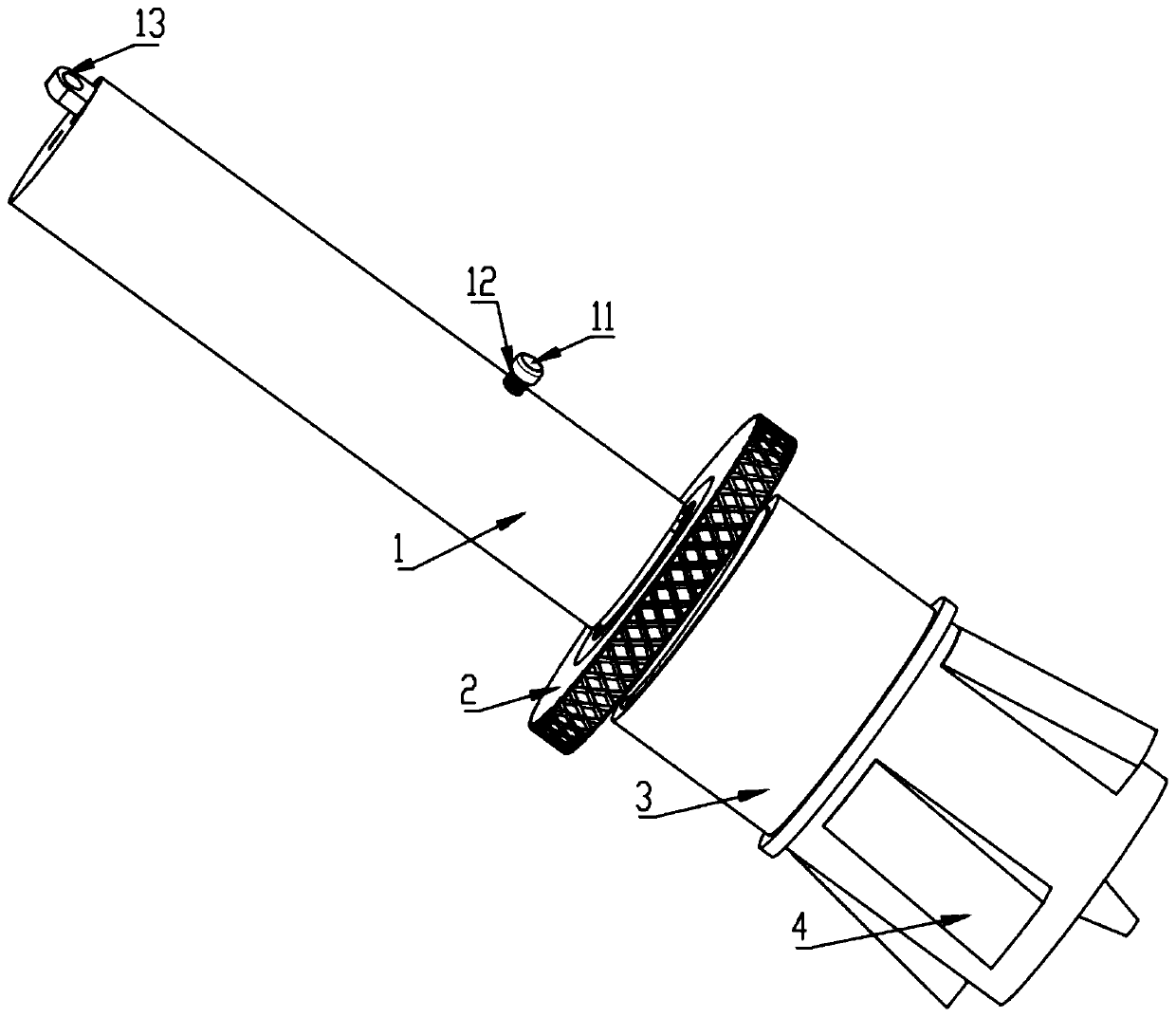

[0039] As shown in the figure, a fastening mechanism for special-shaped thin-walled parts includes a mandrel 1, a locking sleeve 2, a cage 3 and a tension block 4. The mandrel 1 is composed of cylindrical parts and conical parts arranged on the left and right. And the central axes of the cylindrical part and the conical part are collinear, a motor 10 and a battery 13 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com