Radial drilling machine with rapid machining and positioning functions

A radial drilling machine, fast technology, applied in positioning devices, metal processing equipment, components of boring machines/drilling machines, etc., can solve the problems of labor consumption, inconvenient operation, etc., and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

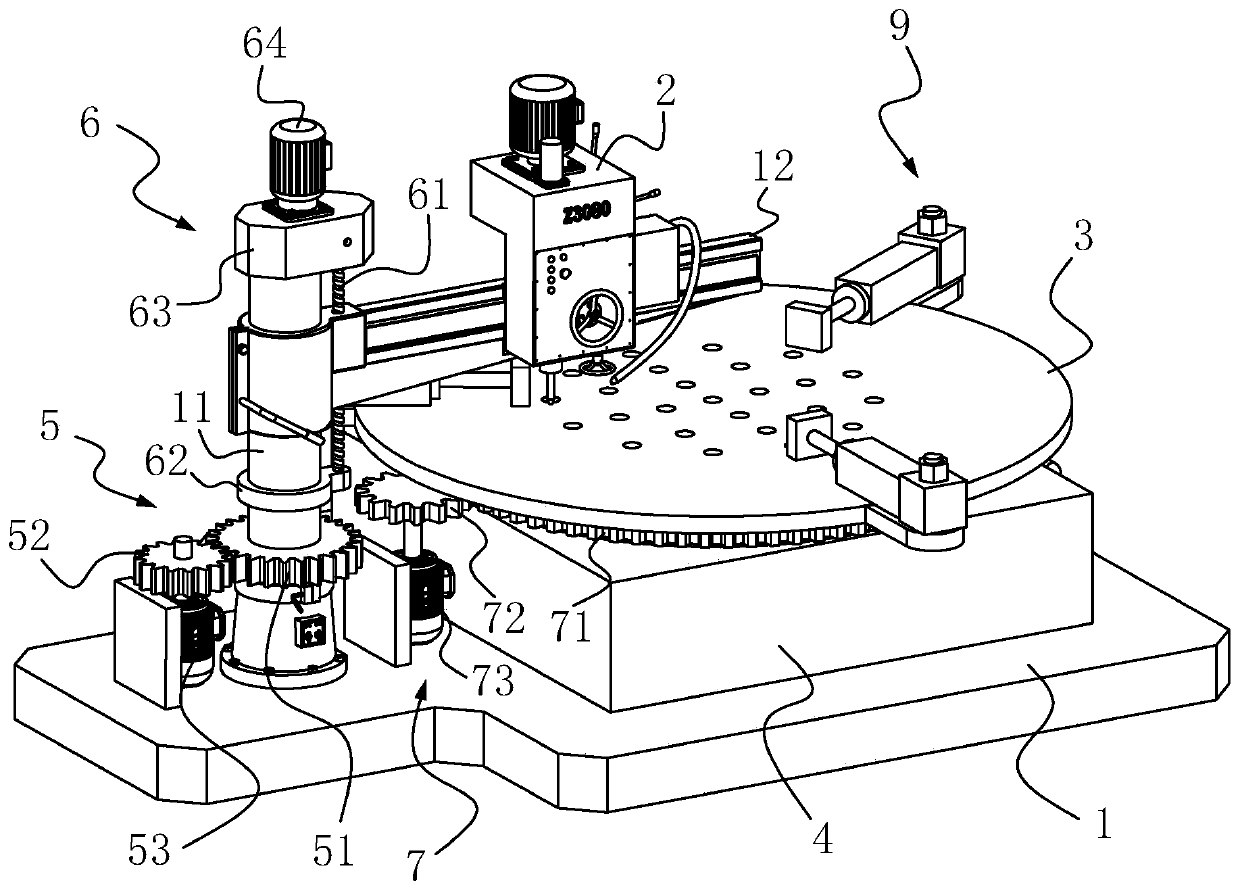

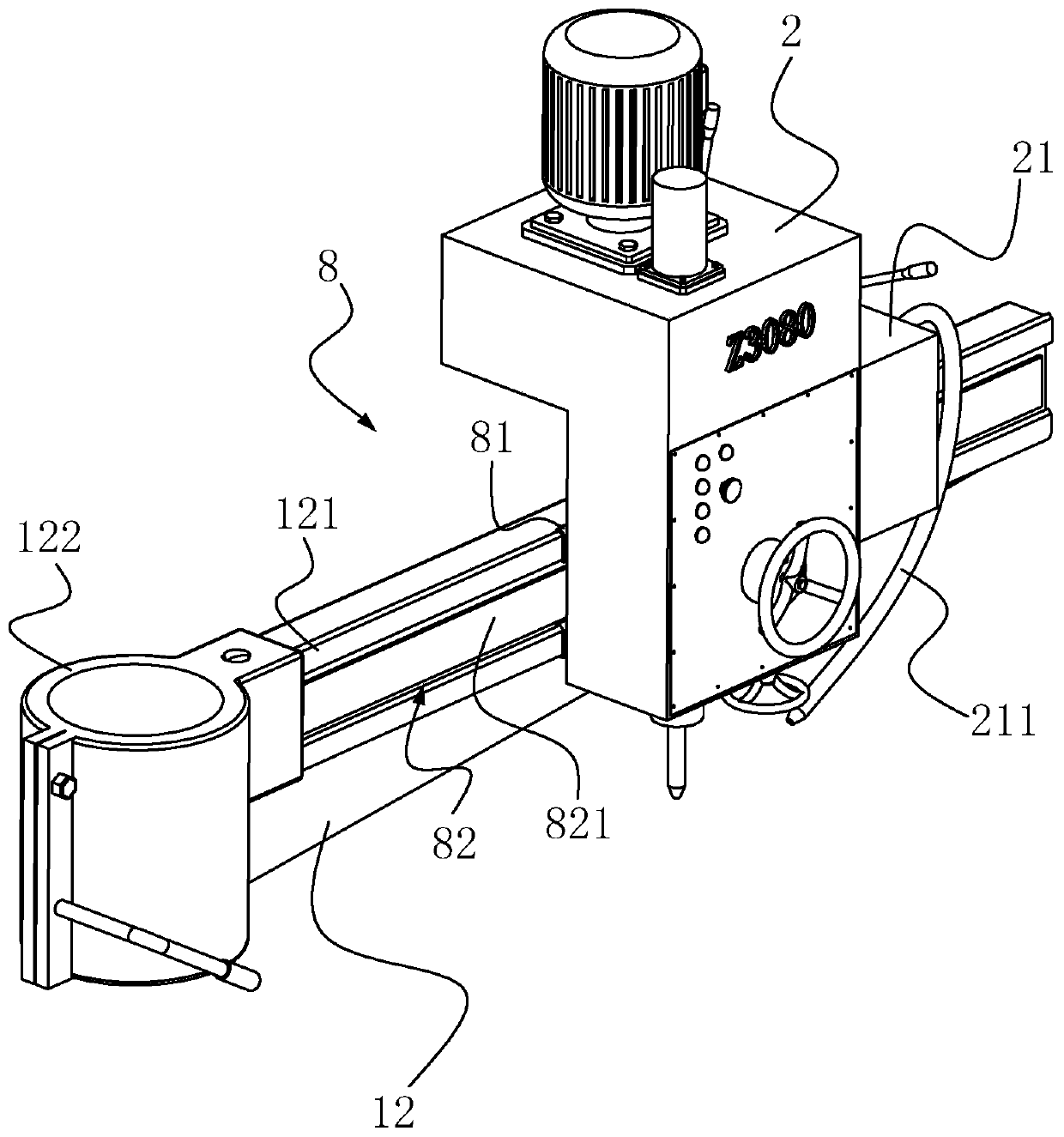

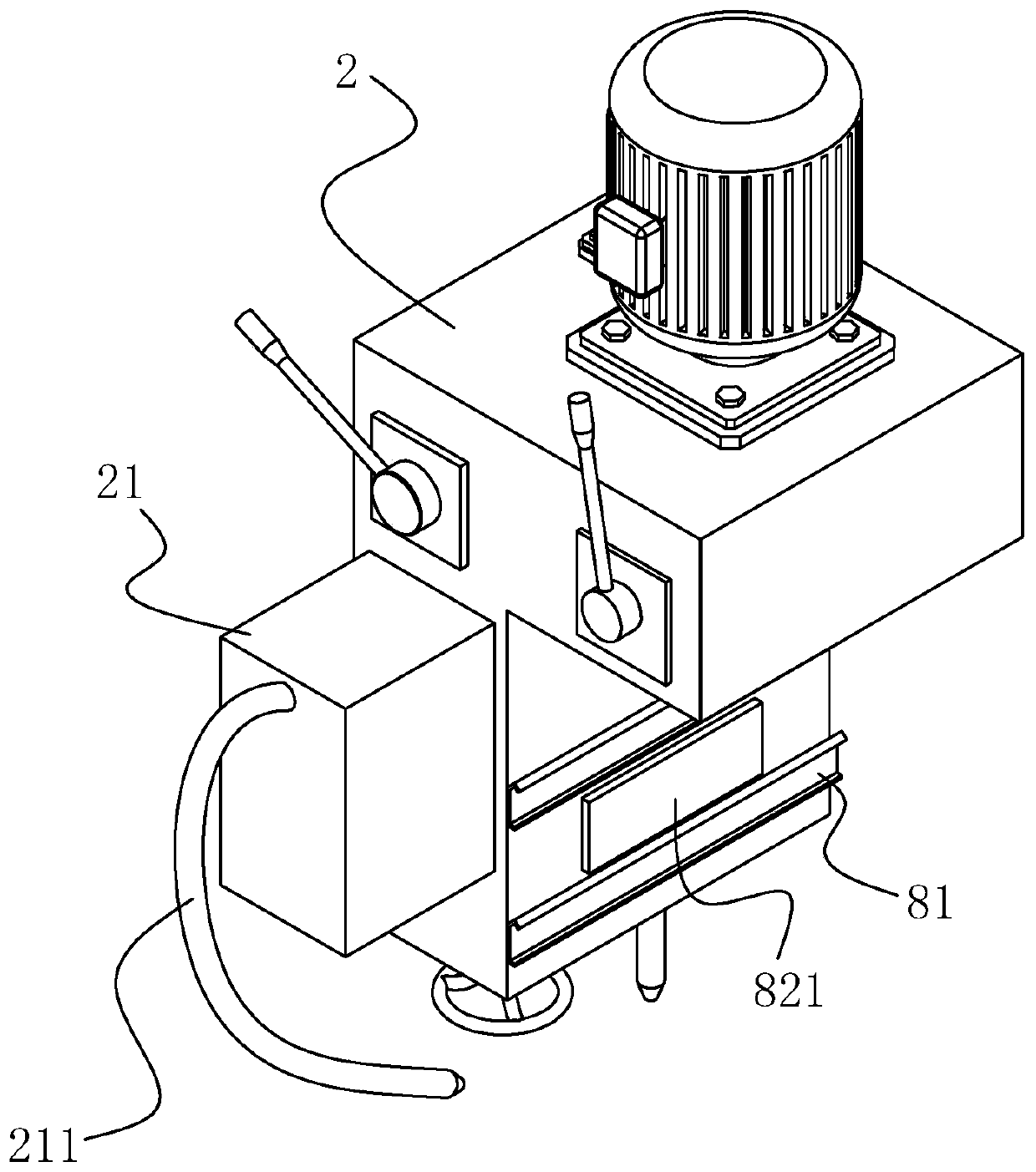

[0037] A radial drilling machine for rapid processing and positioning, hereinafter referred to as a radial drilling machine, refer to figure 1 , including a base 1 , a base 4 , a workbench 3 , a column 11 , a rocker arm 12 and a headstock 2 . The base 1 is set on the ground, and the upright post 11 is vertically set on the base 1 and connected with the base 1 around the axis of the upright post 11 rotatably. The base 4 is arranged on the base 1 for supporting the workbench 3 . The workbench 3 is located on the top of the base 4, and the workbench 3 is cylindrical, and the workbench 3 is connected with the base 4 around its axis in rotation. The upper surface of the workbench 3 is provided with a positioning assembly 9 for fixing the workpiece. One end of the rocker arm 12 is provided with a lifting collar 122, the lifting collar 122 is socketed with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com