Vibrating magnetic needle and magnetic particle composite grinding device

A grinding device and vibrating magnetic technology, applied in the field of polishing, can solve the problems of limited complexity of processing parts, single collision movement of magnetic needles, and low efficiency, and achieve good polishing effect, shorten processing time, and reduce surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

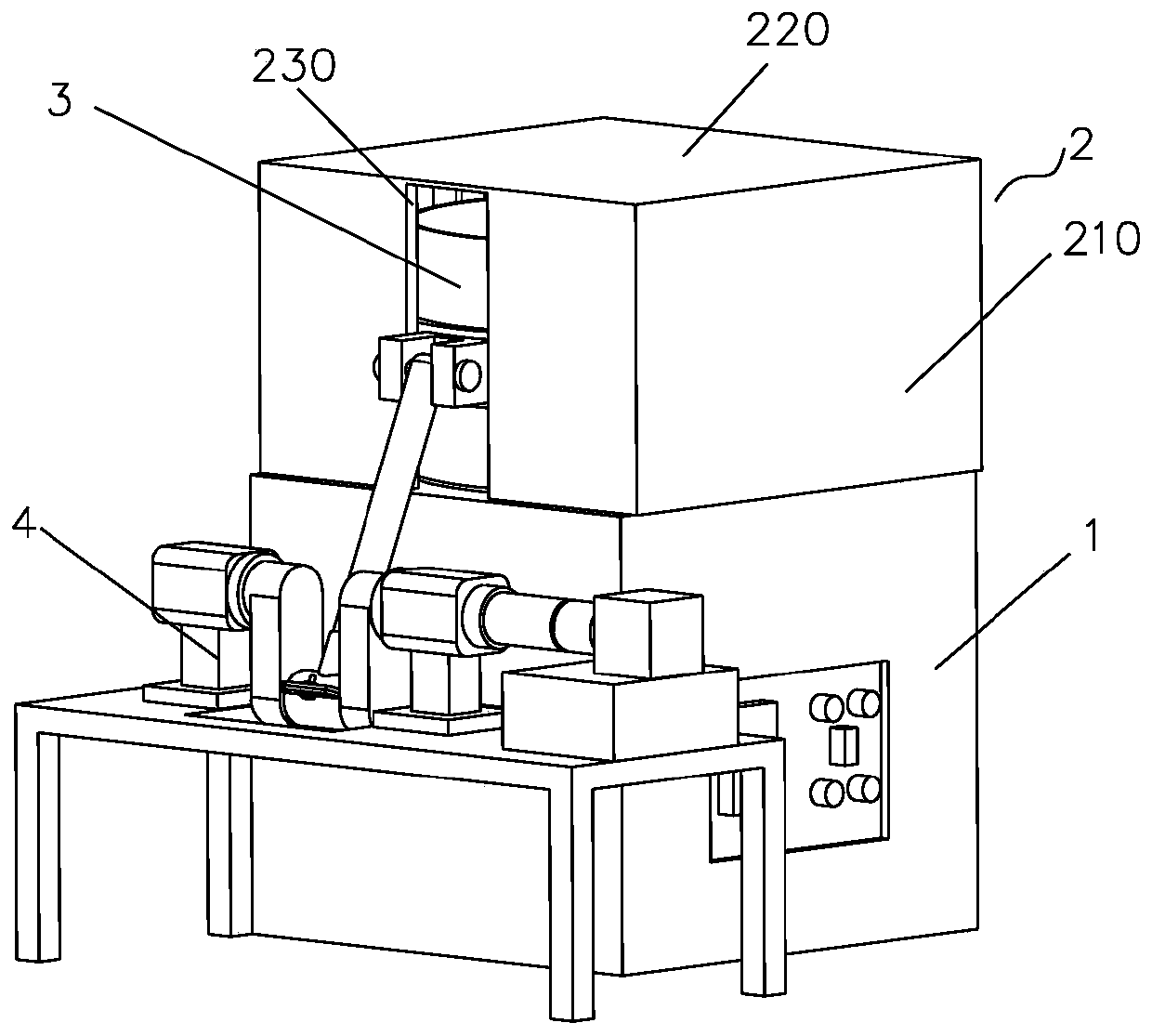

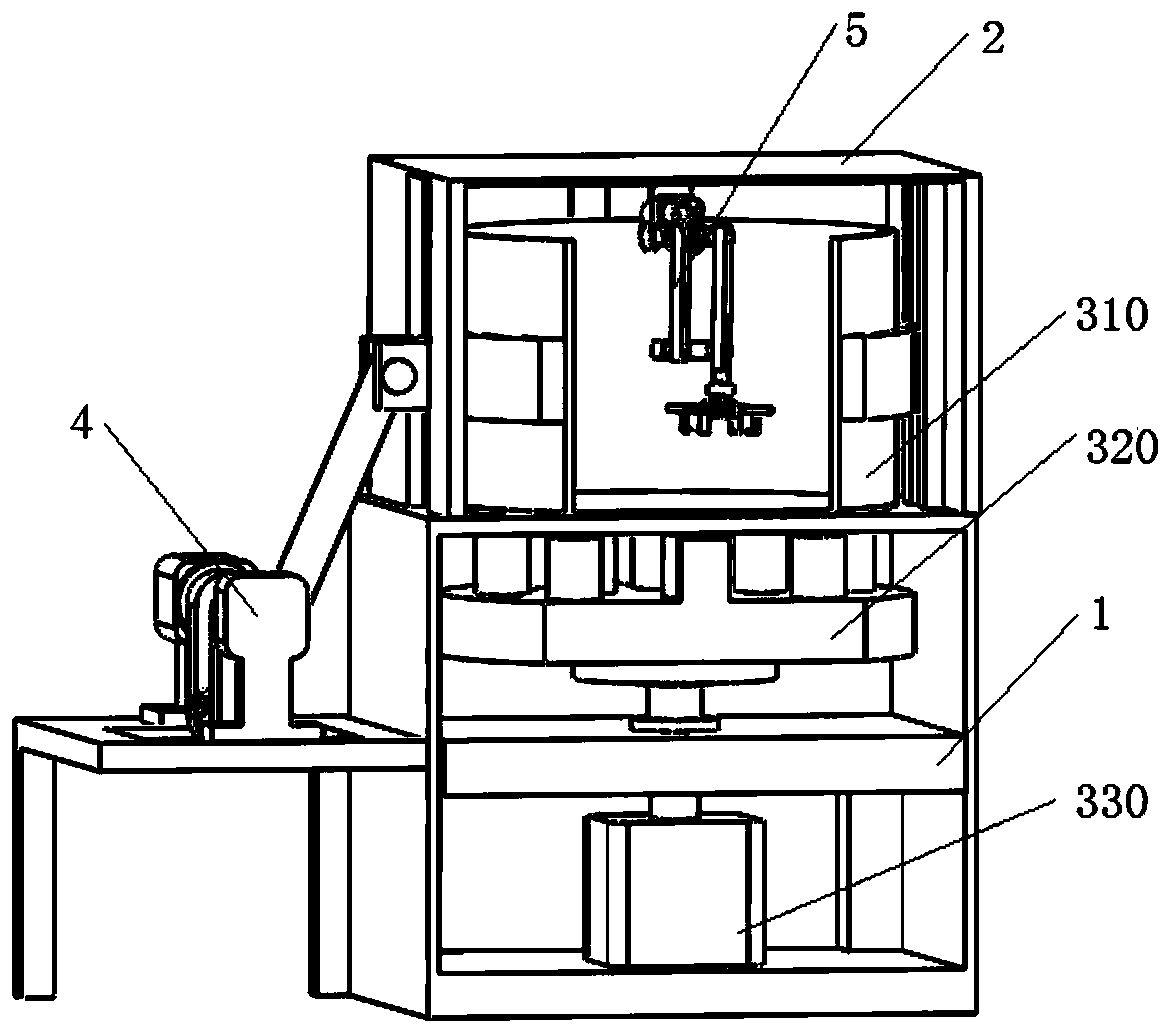

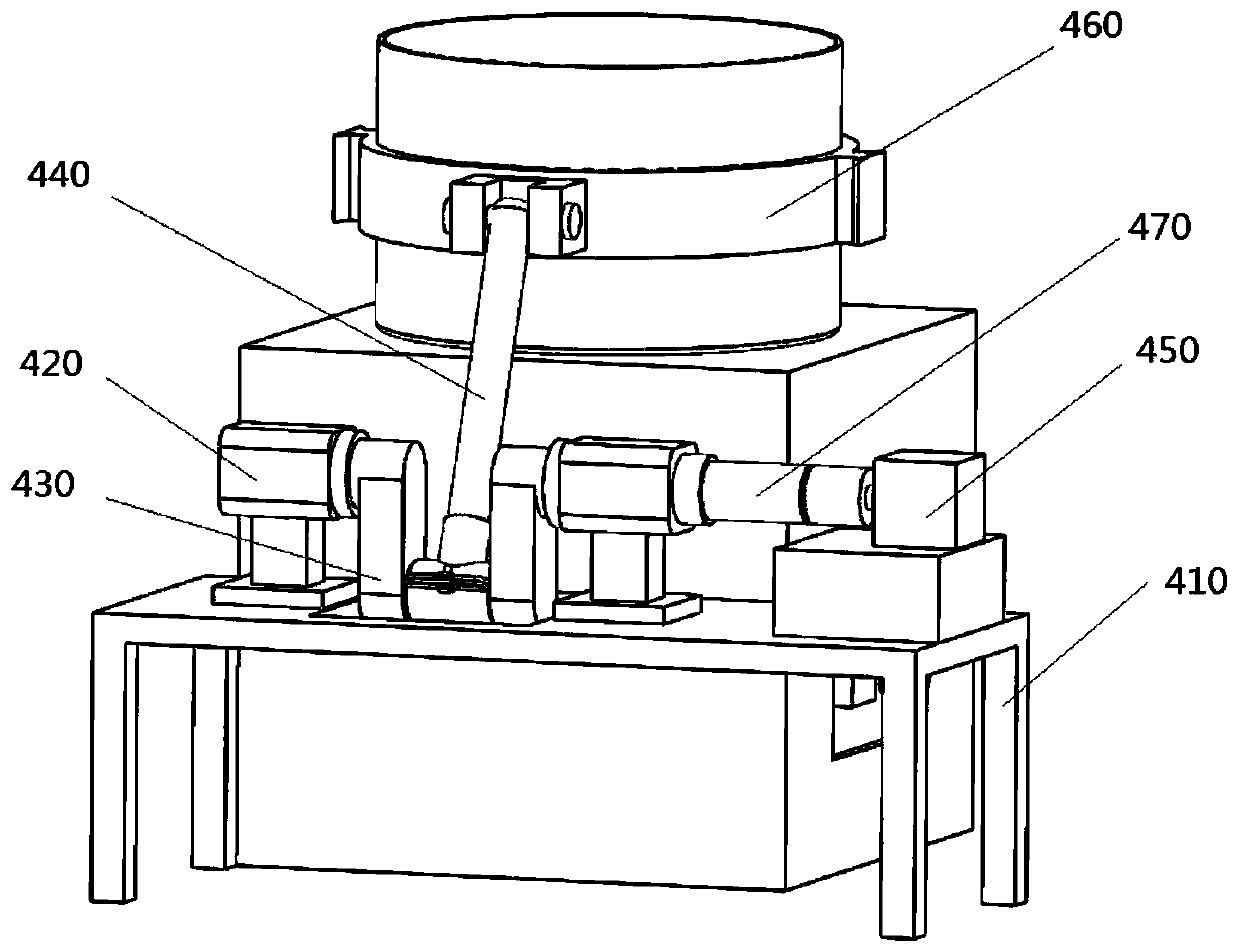

[0029] Such as Figure 1-Figure 5 , a vibrating magnetic needle compound magnetic particle grinding device, comprising a base 1, a cover 2, a grinding mechanism 3, a vibrating mechanism 4, and a grabbing mechanism 5, a cover 2 is arranged above the base 1, and inside the base 1 and the cover 2 A grinding mechanism 3 is provided, a grasping mechanism 4 is provided on the top of the machine cover 2 , and a vibrating mechanism 4 is provided outside the base 1 to connect with the grinding mechanism 3 .

[0030] The grinding mechanism 3 comprises a grinding barrel 310, a magnetic pole plate 320, and a rotating motor 330. The grinding barrel 310 is arranged above the upper plane of the support 1, and the magnetic pole plate 320 is arranged under the upper plane of the support 1, and the magnetic pole plate 320 is driven by the rotating motor 330. rotate.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com