Feed particle processing device

A processing device and feed granule technology, which is applied in raw material extrusion granulation, feed, metal processing, etc., can solve the problems of large size, fixed granule size, and inability to adapt to fat cattle of different sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

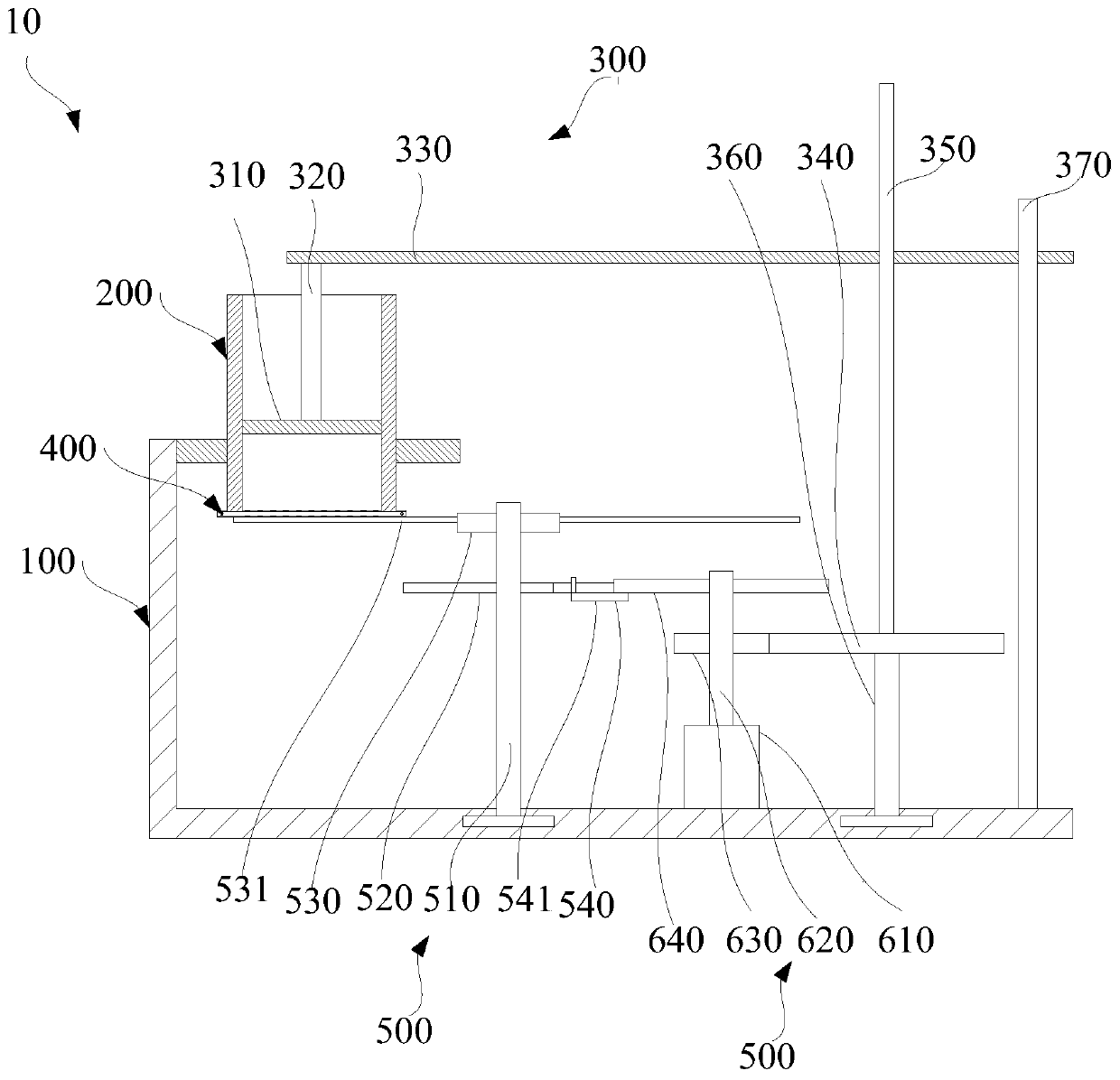

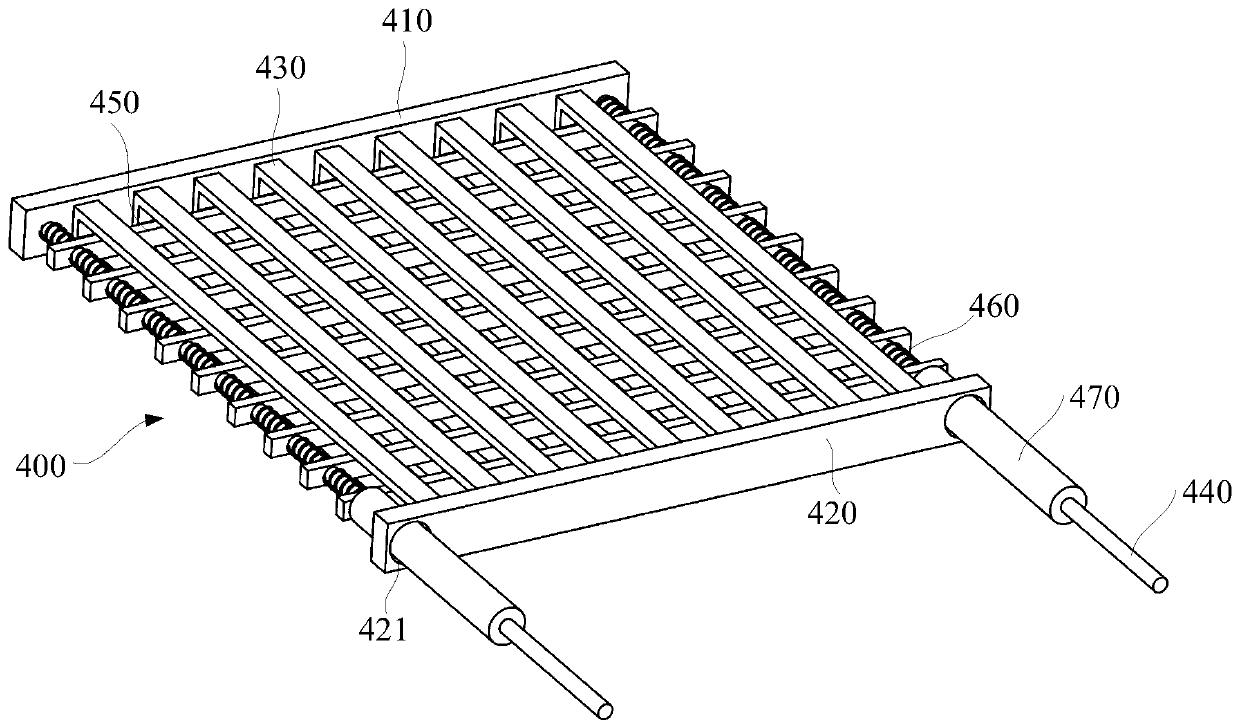

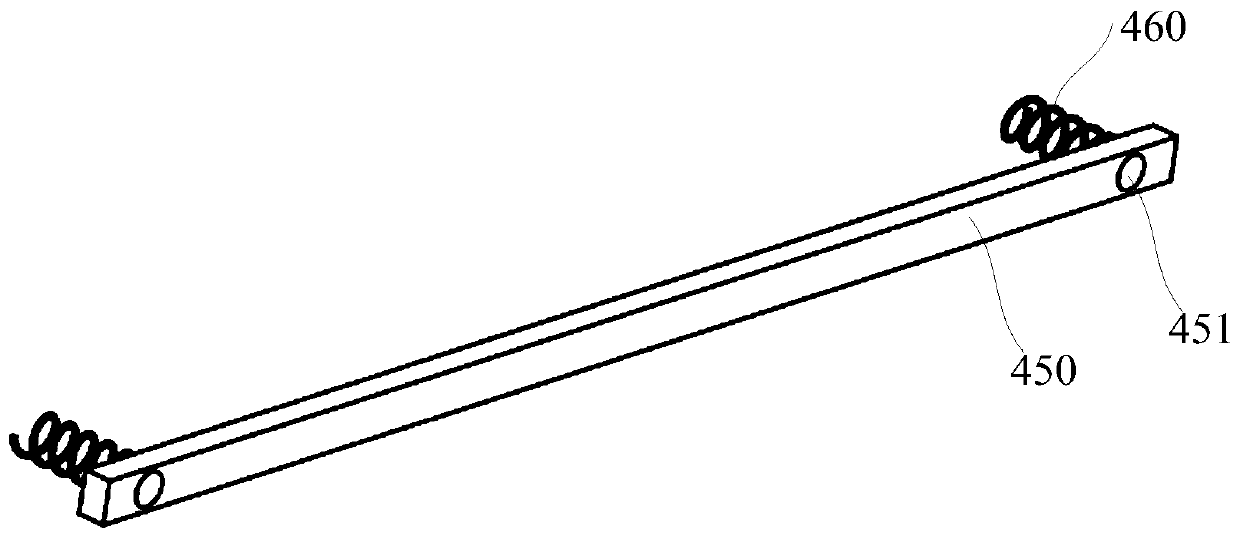

[0023] Such as Figure 1 to Figure 5 As shown, this embodiment provides a feed pellet processing device 10 , which includes a frame 100 , a hopper 200 , an extruding assembly 300 , a screen 400 , a cutting assembly 500 and a rotating drive assembly 600 . It is used to produce granular feed, and the size of the pellets can be adjusted.

[0024] Specifically, the hopper 200 is arranged on the top of the frame 100 . The hopper 200 is a cylindrical body with open upper and lower ends. Hopper 200 may be cylindrical or also prismatic. The hopper 200 is used to store feed, which is dough-like feed that is uniformly mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com