Injection mold for automated production of 64-hole rivet

A technology for injection molds and rivets, which is applied to home appliances, other home appliances, and household components, etc. It can solve the problems of large demand, waste of manpower and time, and increase of production costs, and achieve uniform cooling and avoid burrs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

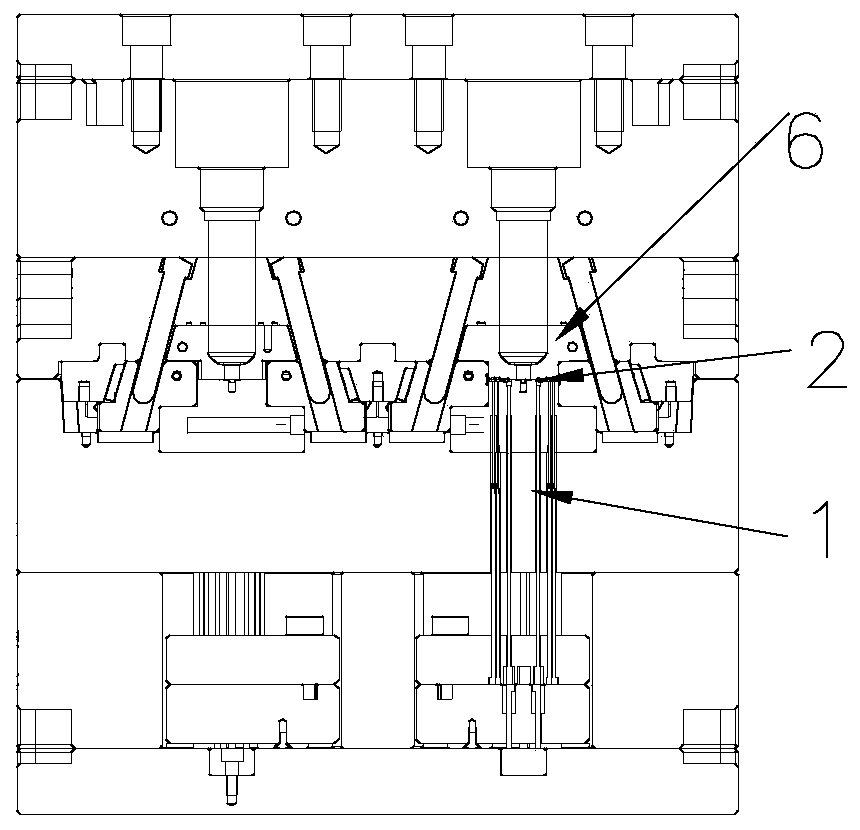

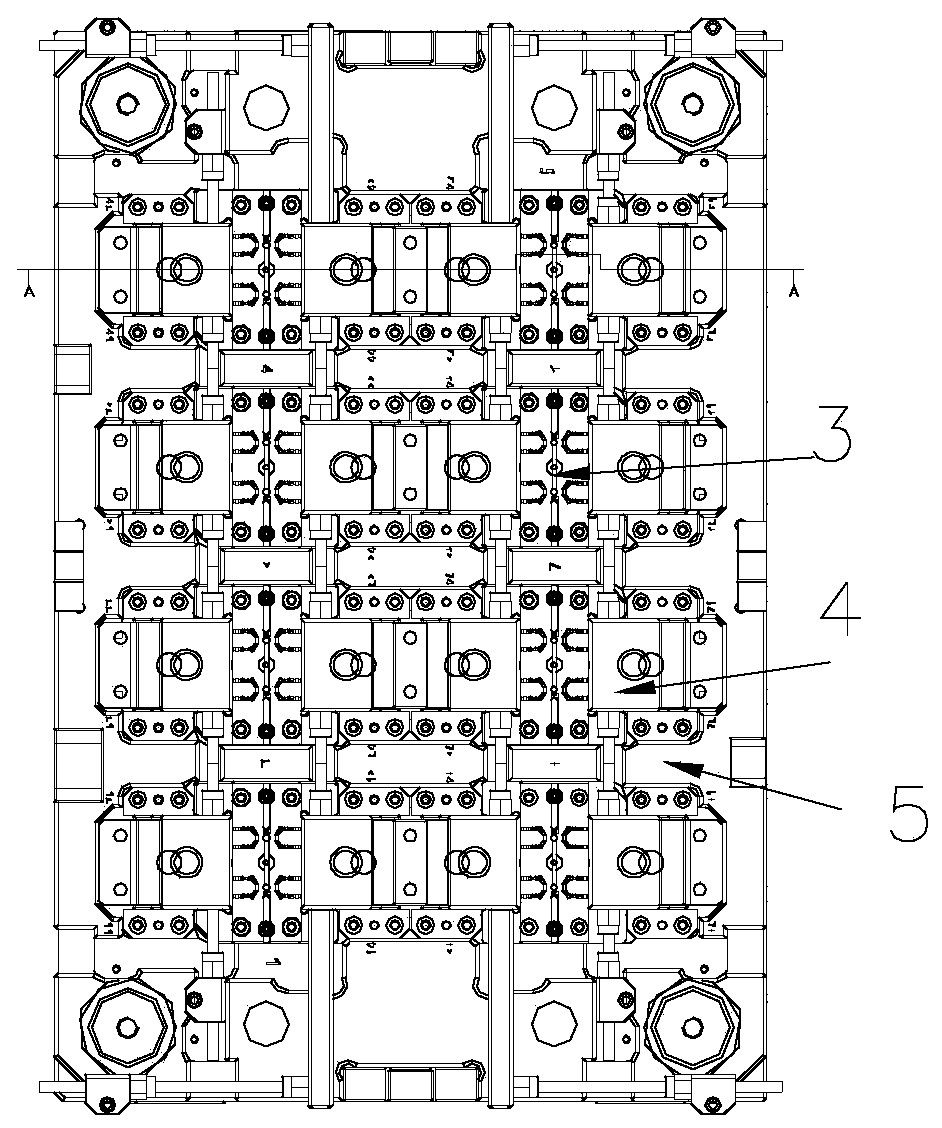

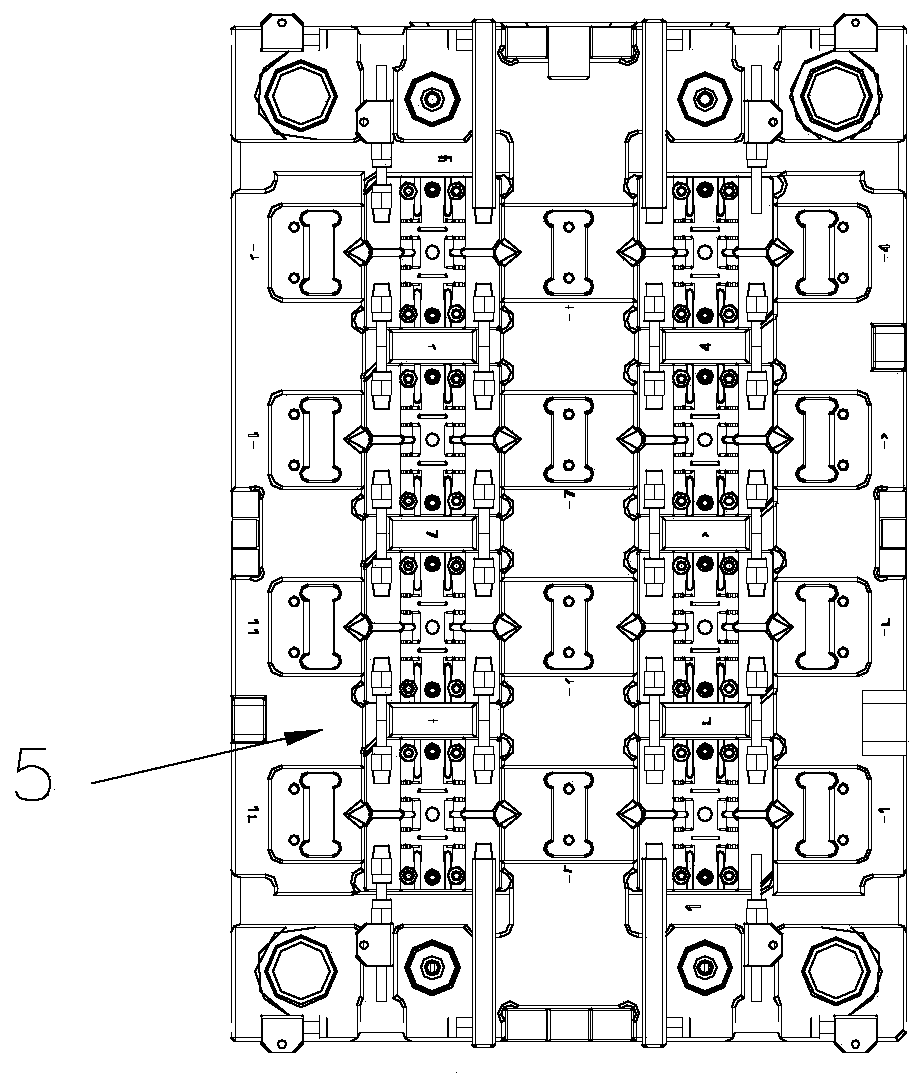

[0041] The development and application of an injection mold for automatic production of 64-hole rivets provided in this example, the main internal structure is as follows Figure 1-3 shown.

[0042]Mainly include: 1. The automatic shearing and separation structure of the runner gate and the product, 2. The design of the side gate that is easy to cut off and prevent wire drawing, 3. The flipping and balancing runner system, 4. The centralized water transportation system for multiple sliders, 5. The mold Frame part, 6. mold core part, 7. hot runner system, 64-cavity rivet automatic production injection mold through multiple innovative structures and systems to realize multi-cavity rivet products without manual automatic production, and high quality to meet product quality Require. In this case, 1. The runner gate and product automatic shear separation structure, which is installed in the movable mold part, is mainly related to the movable mold core, movable template, upper ejec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com