Manufacturing method of PVC anti-skid heat preservation tarpaulin

A production method and tarpaulin technology, which are applied in chemical instruments and methods, lamination auxiliary operations, lamination and other directions, can solve the problems of no production method and cumbersome production of tarpaulin, and achieve simple production, stable temperature and good use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

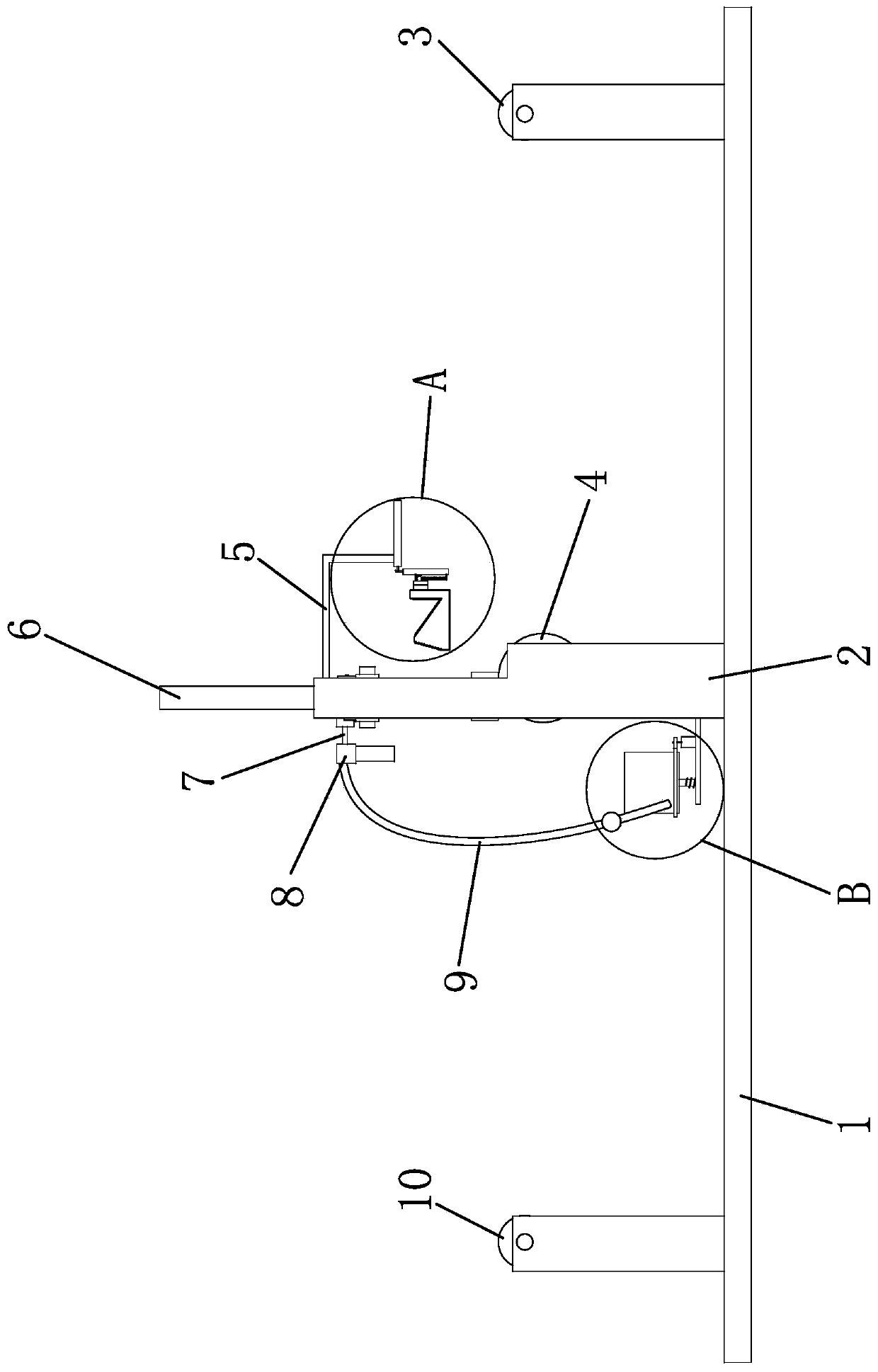

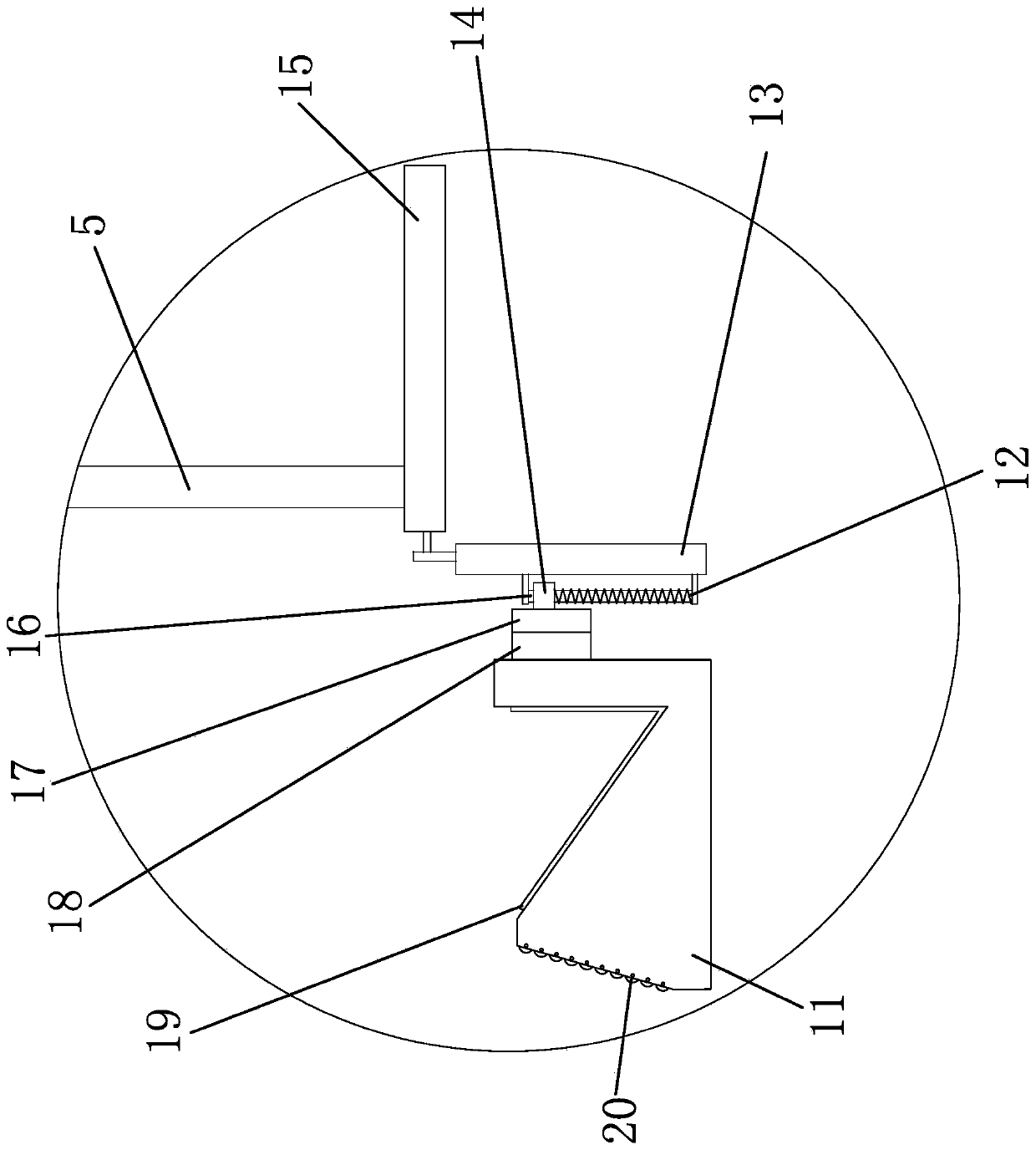

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

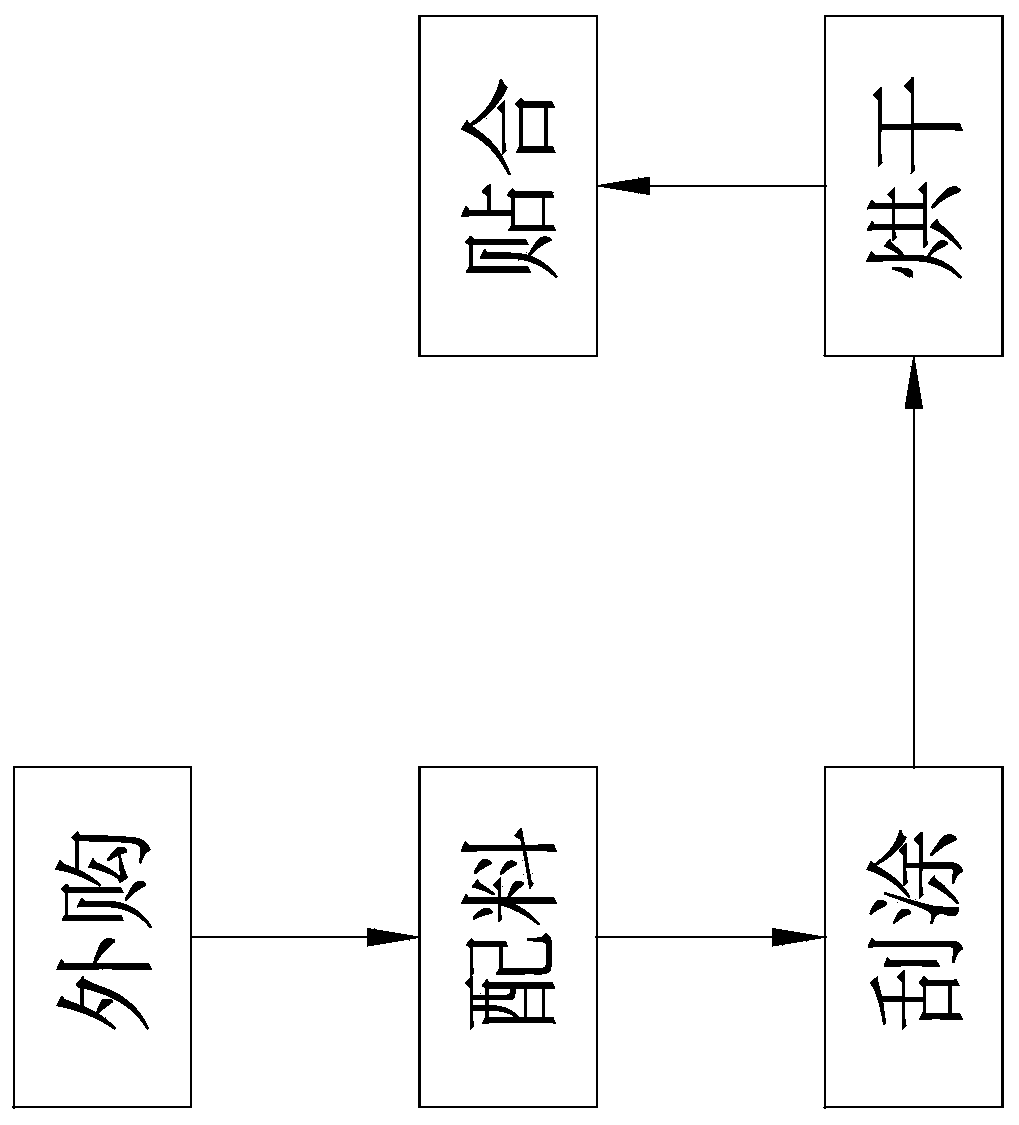

[0034] Such as Figure 1-Figure 6 Shown, the manufacture method of this PVC non-slip thermal insulation tarpaulin comprises the following steps:

[0035] a. Outsourcing: purchase existing polyester canvas, foaming coils and heating wires in the market;

[0036] b. Ingredients: by weight, weigh 100 parts of PVC paste resin, 50-70 parts of plasticizer, 2-8 parts of stabilizer, 5-15 parts of flame retardant, 10-16 parts of anti-fungal agent, anti-aging 3-9 parts of the agent and 2-10 parts of the pigment are put into a mixer and heated and stirred evenly to obtain a paste; in this embodiment, 100 parts of PVC paste resin and 60 parts of plasticizer are weighed in parts by weight , 4 parts of stabilizer, 7 parts of flame ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com