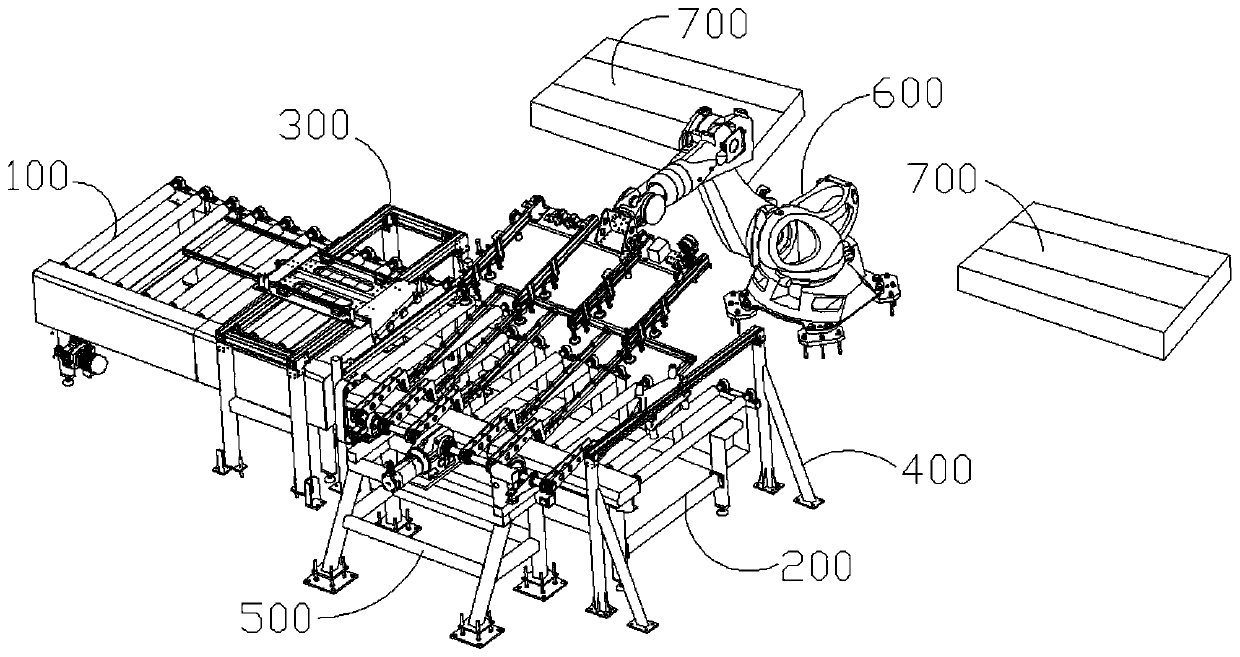

Grabbing and stacking system for photovoltaic glass deep machining

A technology for photovoltaic glass and deep processing, applied to lighting and heating equipment, conveyor objects, furnaces, etc., can solve the problems of low efficiency and low cost of manual unloading, achieve intelligence and modularization, ensure glass quality, meet The effect of quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

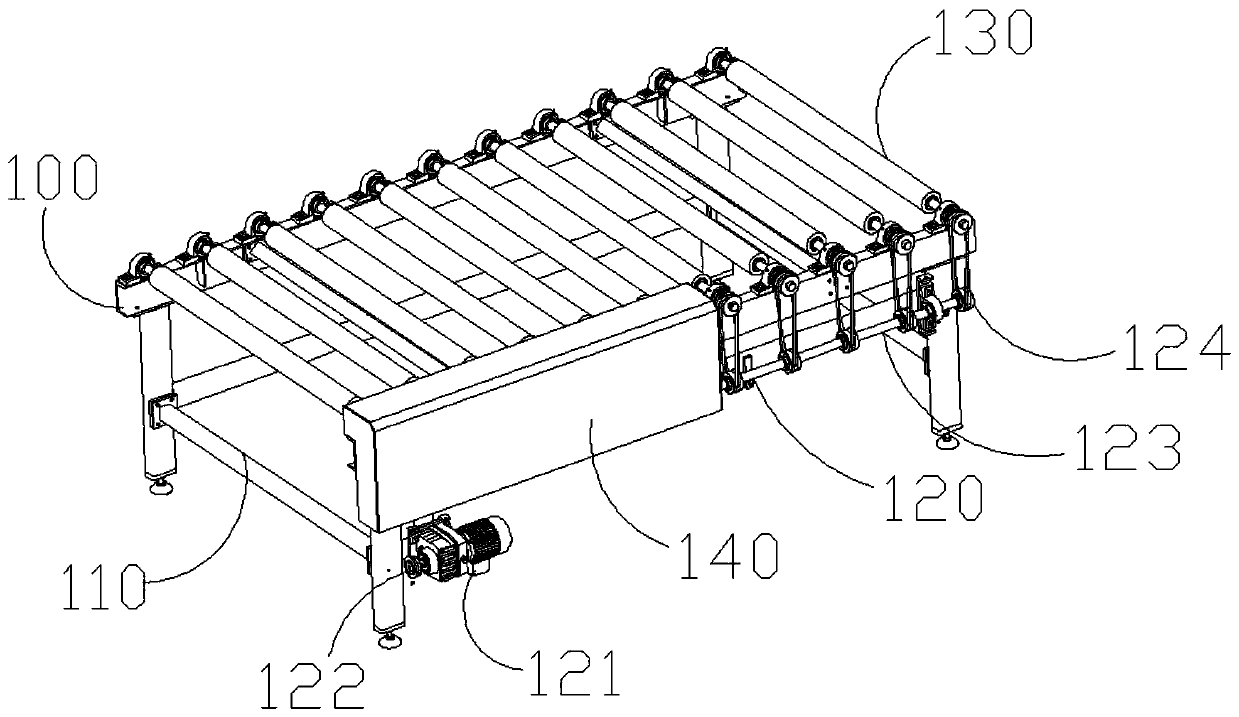

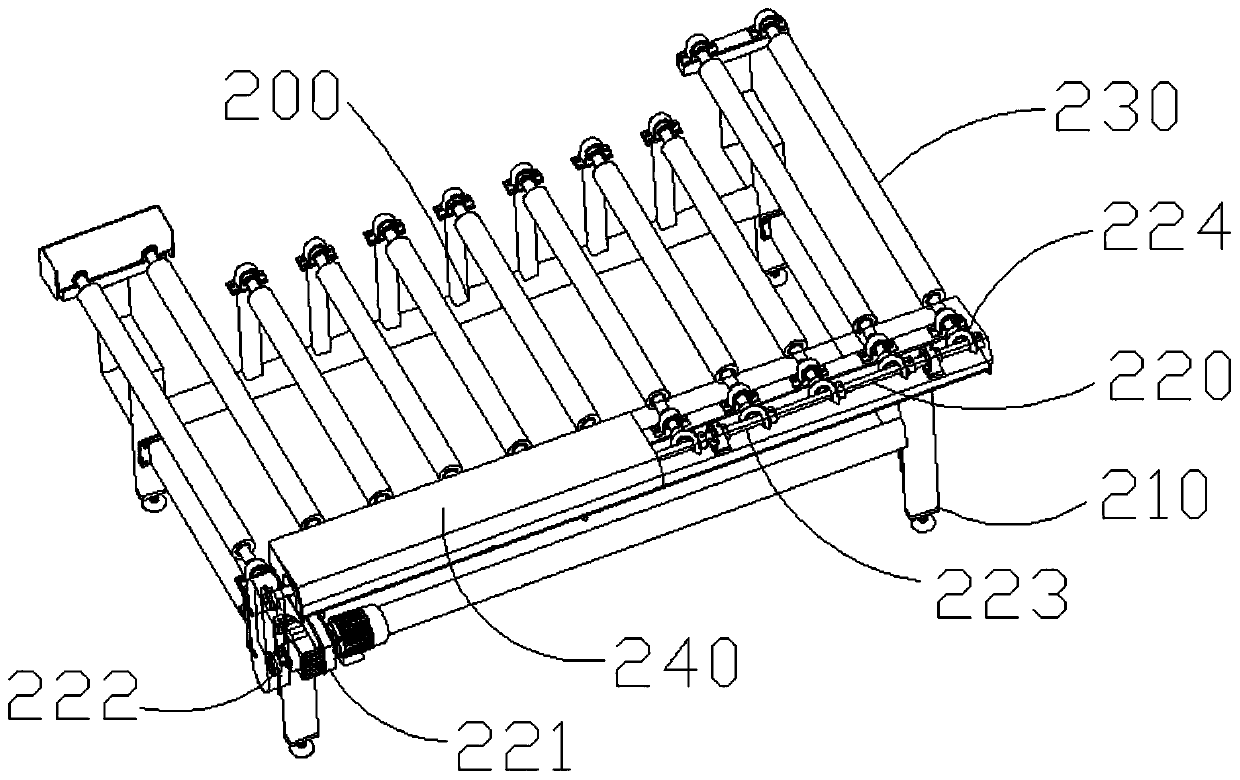

[0102] Such as figure 1 As shown, after the short side of the glass enters the conveying roller table 100 forward, it continues to be transported forward to the grabbing roller table 200, and the glass decelerates on the grabbing roller table 200 and stops at the set stop position. At this time, the manipulator 600 has been on standby to grab the bottom of the roller table 200. After the glass stops, the manipulator 600 moves upward horizontally, and the glass is lifted by the suction cup assembly 630 on the manipulator 600. At this time, the suction cup blows out compressed air, and the cylinder 610 carries The positioning wheel is stretched out, and the manipulator 600 is raised from a horizontal position to a certain angle. Since the suction cup blows air at this time, there is a layer of air between the suction cup and the glass, and the friction force is very small. On the two positioning wheels, the long side of the glass is now positioned.

[0103] At this time, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com