Rotatable hydraulic cantilever lifting device

A hydraulic and cantilever technology, applied in the direction of transportation and packaging, cranes, etc., can solve the problems of easy shaking, difficult to guarantee precision, difficult to control precision, etc., and achieve the effect of stable lifting process, fast lifting and large lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

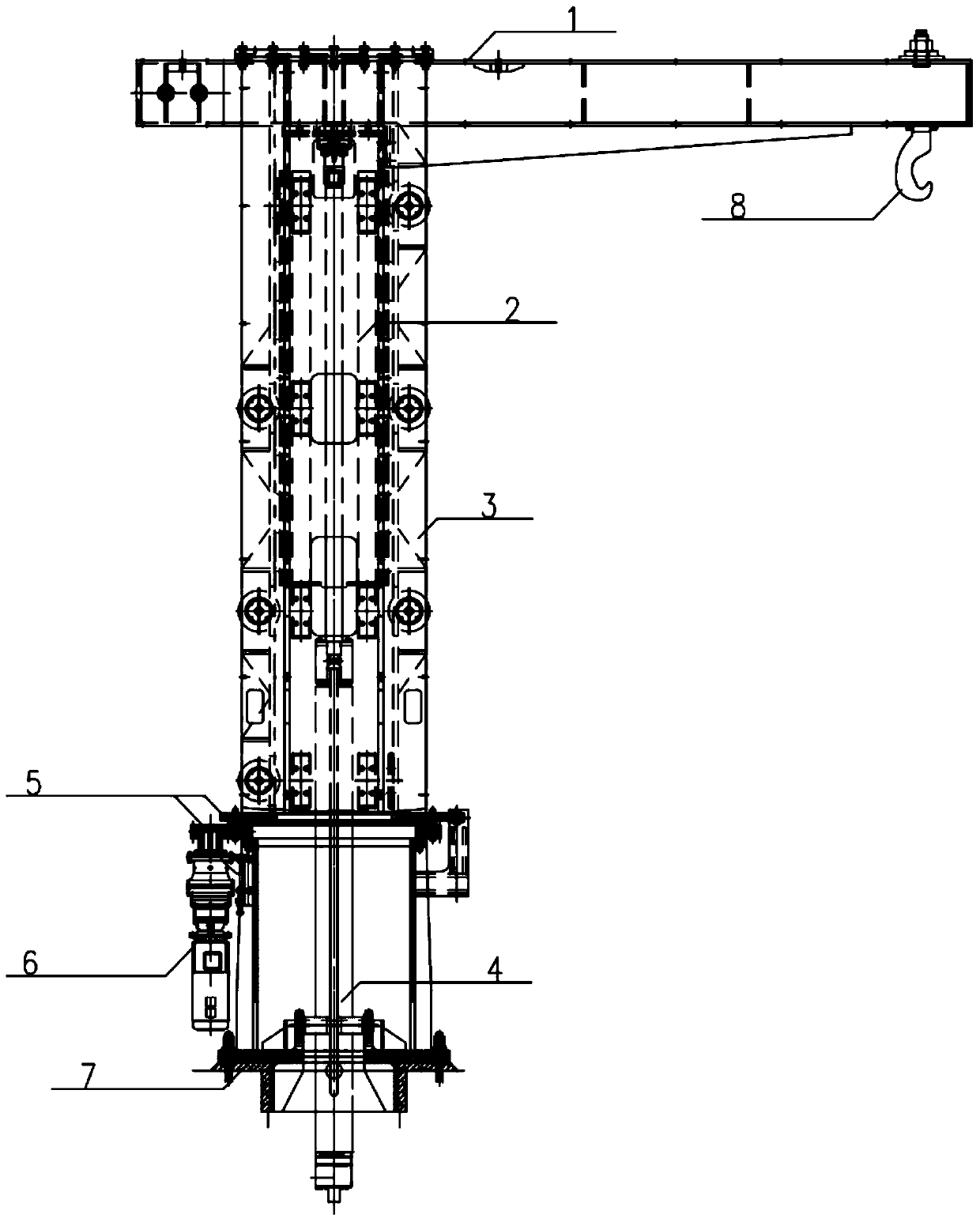

[0049] Such as figure 1 As shown, the rotatable hydraulic cantilever lifting device includes a lifting arm 1 , a base 7 and a hook 8 .

[0050] Wherein, the base 7 is fixed on the civil foundation; one side of the base 7 is provided with a rotating motor 6;

[0051] The upper end of the base 7 is sequentially provided with a slewing bearing 5 and an outer cylinder 3 of the lifting device; the outer cylinder 3 of the lifting device is connected by a slewing pair formed by the slewing bearing 5 and the base 7 with a vertically arranged rotary shaft;

[0052] The outer cylinder 3 of the lifting device is driven to rotate by a rotating motor 6;

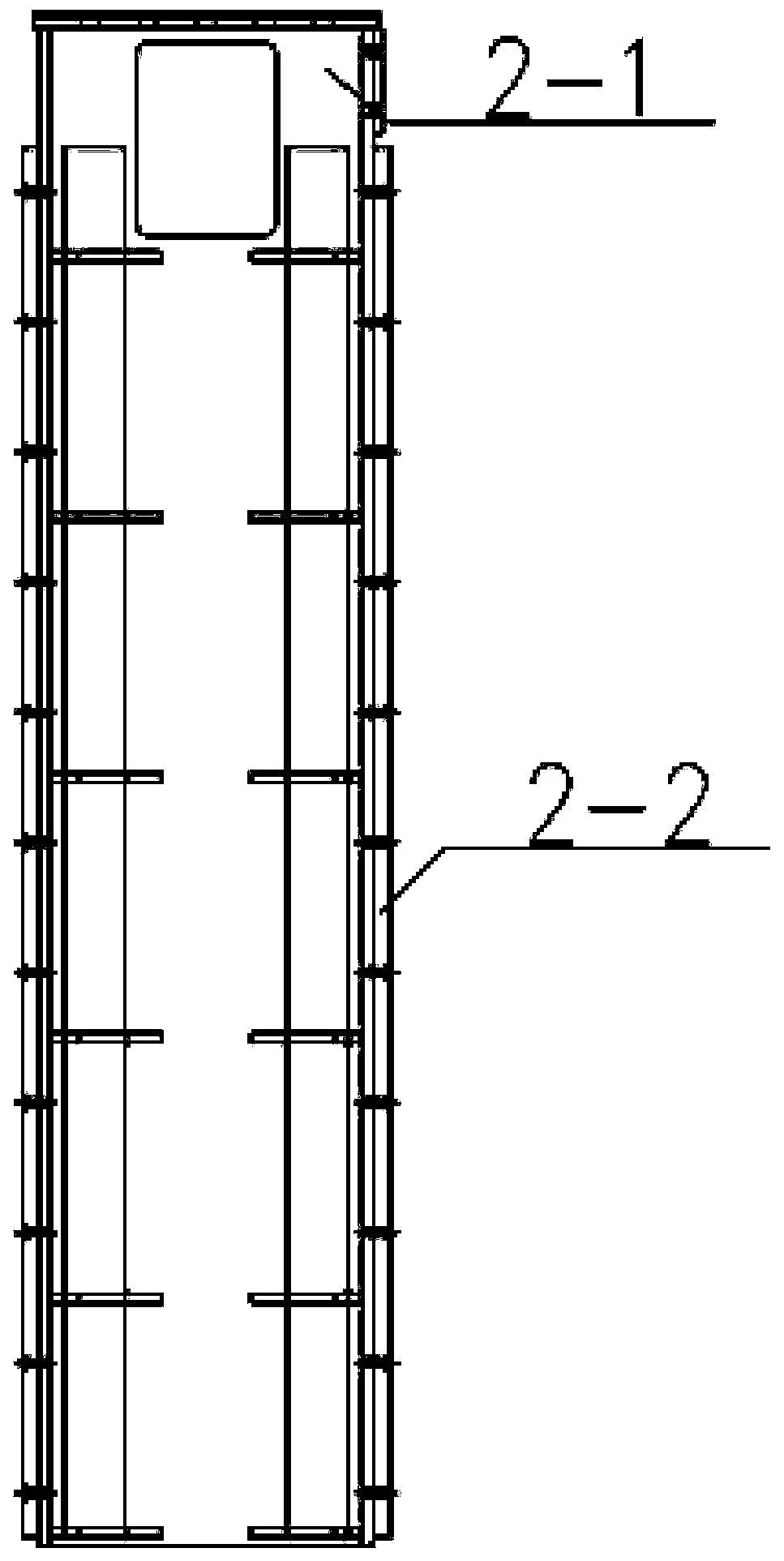

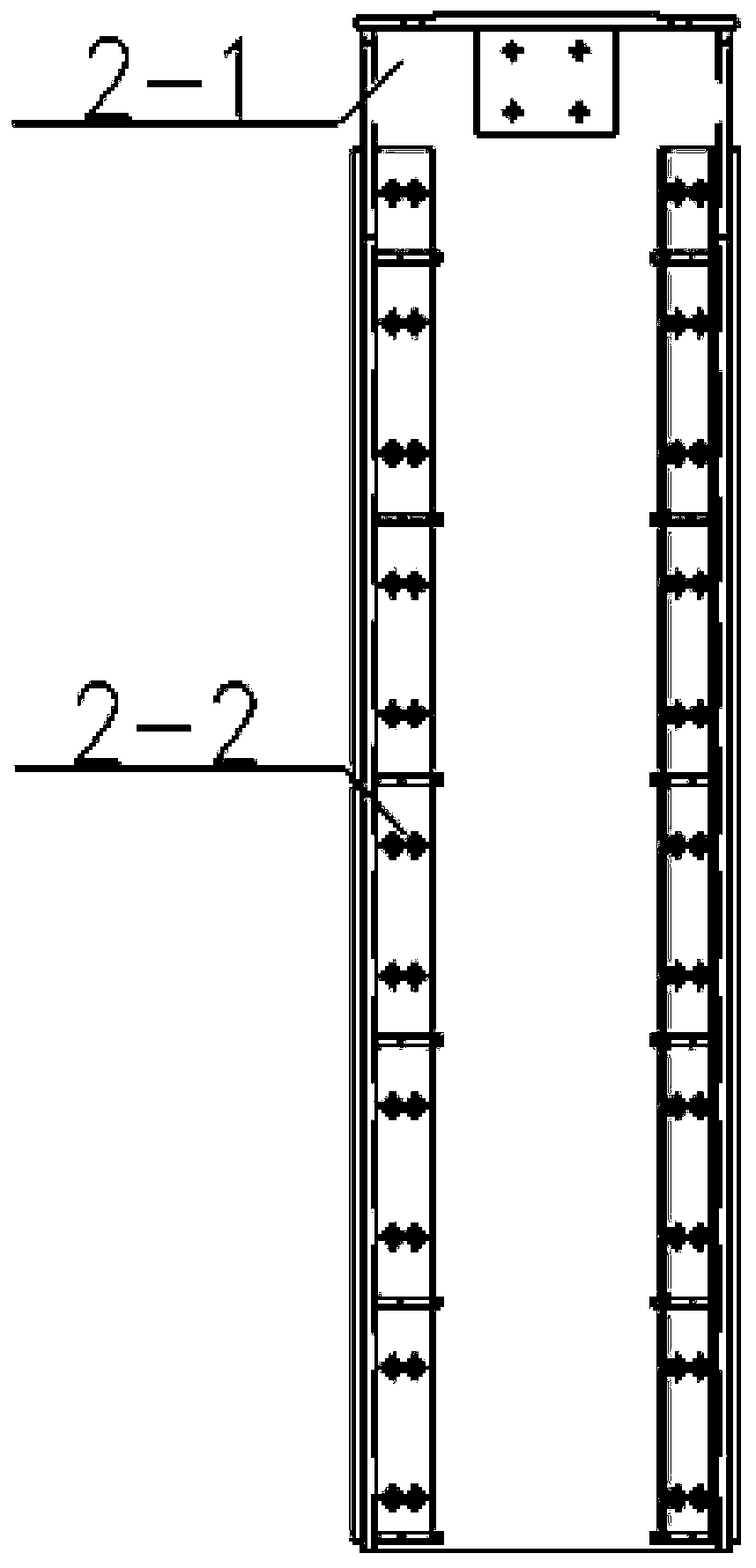

[0053] The inner cylinder 2 of the lifting device is arranged in the outer cylinder 3 of the lifting device. There is a moving pair between the outer cylinder 3 of the lifting device and the inner cylinder 2 of the lifting device. The inner cylinder 2 of the lifting device can move back and forth along the vertical direction; the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com