A non-contact and efficient low-temperature evaporation system for landfill leachate

A technology of landfill leachate and low-temperature evaporation, which is applied in the treatment of polluted groundwater/leachate, special treatment targets, chemical instruments and methods, etc. Adapt to small-scale leachate treatment and other problems, to achieve the effect of improving thermal efficiency and energy saving, reducing maintenance costs, reducing maintenance costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

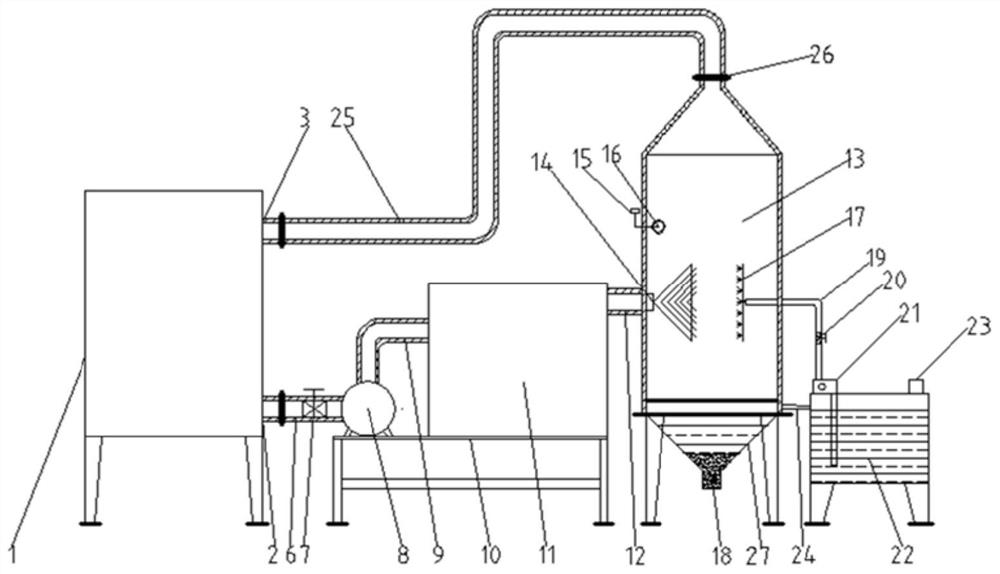

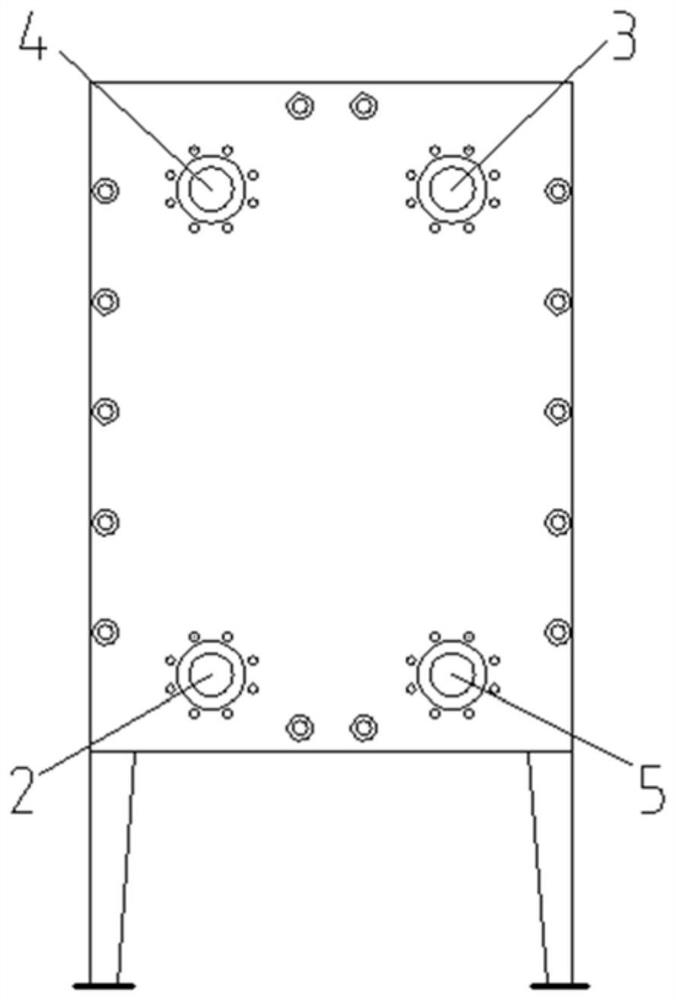

[0036] A contactless and highly efficient low-temperature evaporation system for landfill leachate, e.g Figures 1 to 2 Shown, comprising an evaporator 13, a stock tank 22, an electric hot air generator 11 and a heat pump mechanism 1, wherein: the evaporator 13 has a steam outlet 26 and a concentrate outlet 27, the interior is provided with a hot gas release mechanism 14 for gas-liquid horizontal convection contact and a atomization nozzle mechanism 17; The stock tank 22 is connected to the atomization nozzle mechanism 17 within the evaporator 13 through the infusion tube 19, and the stock tank 22 is provided with an inlet for connecting with the external leachate; Electric hot air generator 11 is connected to the hot gas release mechanism 14; Heat pump mechanism 1 has a cold air inlet 4, a hot air outlet 2, a steam inlet 3 and a condensate outlet 5, and the steam inlet 3 is connected to the steam outlet 26 of the evaporator 13, and the hot air outlet 2 is connected to the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com