Ditch nitrogen and phosphorus degradation equipment

A technology for nitrogen and phosphorus and equipment, which is applied in the field of nitrogen and phosphorus degradation equipment in ditches, can solve the problems of high cost, consuming manpower and material resources, pollution, etc., and achieves the effect of complete functions, compact structure and improvement of habitat conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

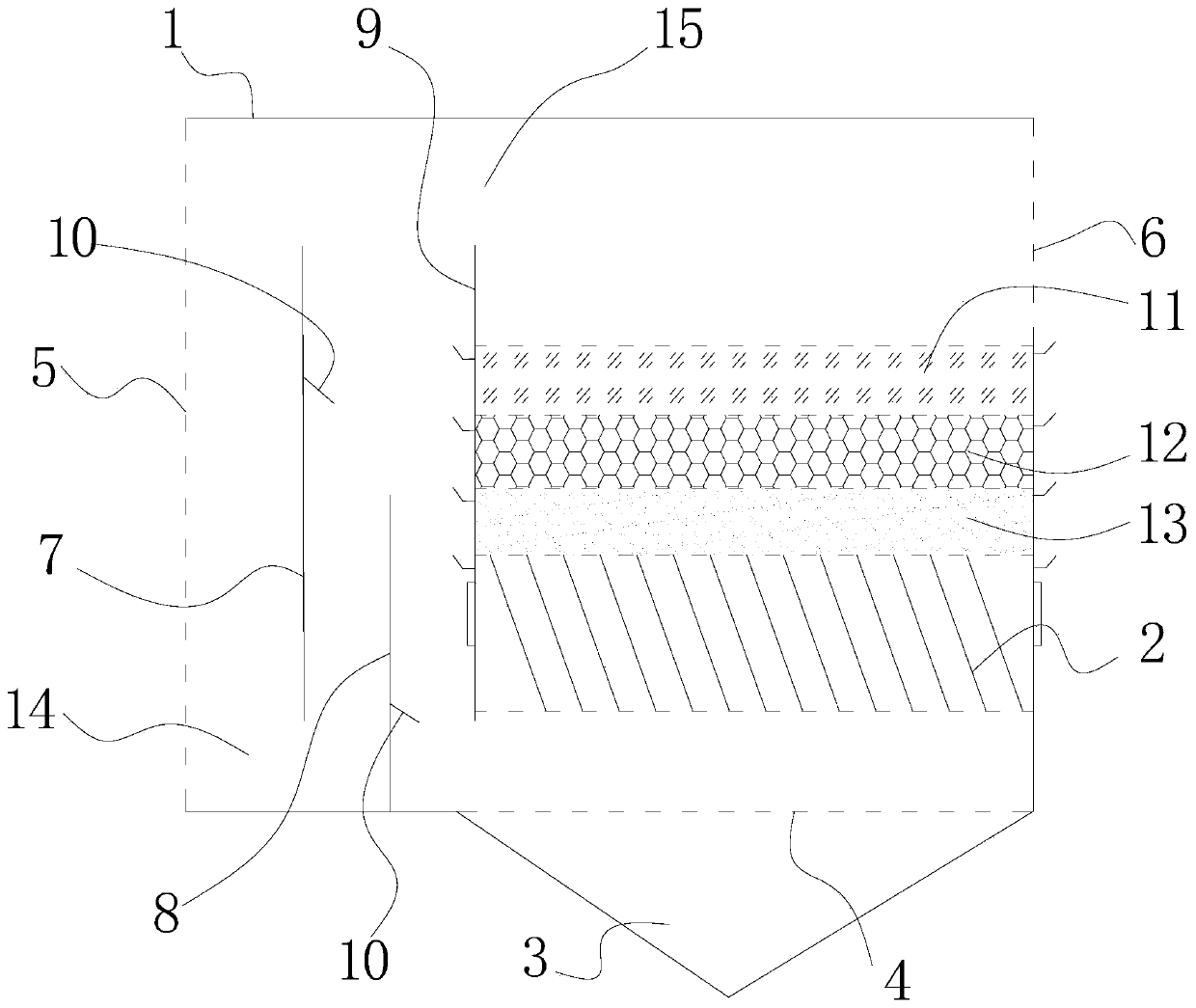

[0011] Such as figure 1 As shown, the ditch nitrogen and phosphorus degradation equipment is equipped with a sedimentation tank body 1, inclined pipe filler 2, and nitrogen and phosphorus removal components.

[0012] The sedimentation tank body 1 is an integral structure welded by metal plates, and a runoff area and a sedimentation area 3 are arranged inside it. The runoff area is in the shape of a cuboid, the sedimentation area 3 is in the shape of a triangular prism, and the sedimentation area 3 is located on one side of the runoff area; there is a grid I4 between the runoff area and the sedimentation area 3, and the runoff area and the sedimentation area 3 are connected. Both ends of the sedimentation tank body 1 are open structures, one end of the runoff area is directly connected to one end of the sedimentation tank body 1 , and the other end of the runoff area is directly connected to one end of the sedimentation tank body 1 . One end of the runoff area is the input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com