A kind of method for continuous synthesis of perchloromethanethiol

A technology of perchloromethanethiol and chloromethylmercaptan, which is applied in the field of continuous synthesis of perchloromethanethiol, can solve the problems of workers' health hazards, increase labor costs, and reduce selectivity, so as to improve reaction safety and Controllability, reduction of liquid chlorine gasification process, and improvement of reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

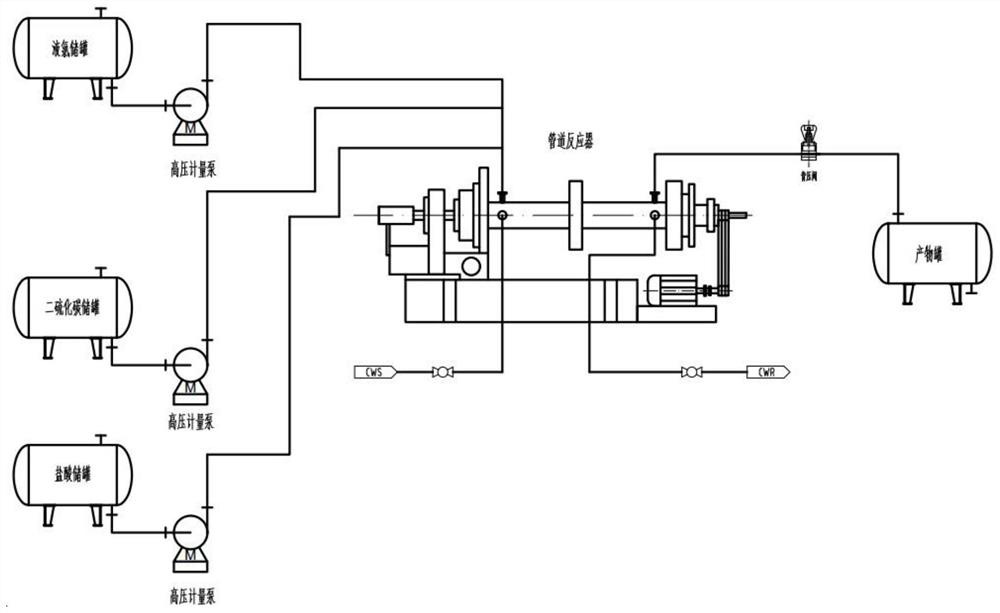

Method used

Image

Examples

Embodiment 1

[0044] Using liquid chlorine, carbon disulfide, and dilute hydrochloric acid (12%) as raw materials, use a high-pressure pump to pump them into the microchannel reactor under pressure, wherein the flow rate of liquid chlorine is 0.620L / h (12.5mol / h), and the flow rate of carbon disulfide is 0.150L / h (2.5mol / h), the hydrochloric acid flow rate is 0.536L / h, the reaction temperature is controlled at 15±1°C, the reaction pressure is 1Mpa, and the residence time is 1.5min. The raw materials enter the pressure storage tank after the microchannel reaction is completed, and the content of carbon disulfide in the oil phase is less than 3% after sampling and measurement, and the reaction is considered to be completed. After 1 hour of continuous production, 457.8g of the product was obtained, the content of perchloromethanethiol was 99.7%, and the yield was 98.4%, CS 2 The conversion rate is 99.4%, and the selectivity is 99.0%.

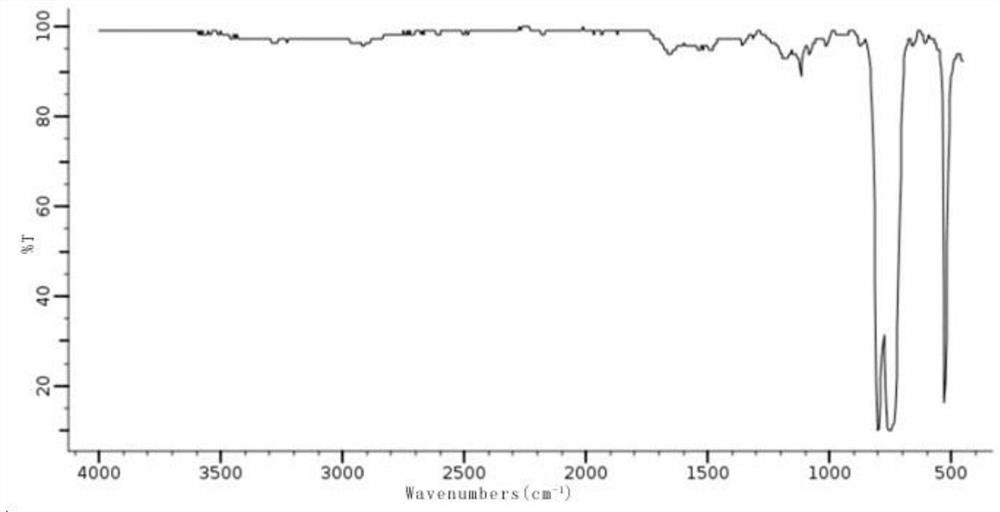

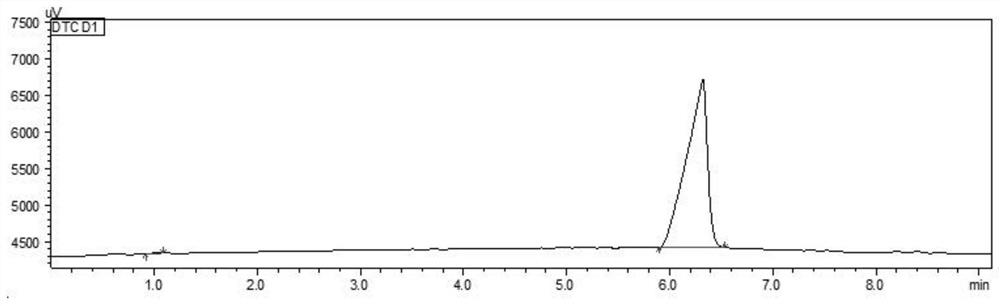

[0045] product testing:

[0046] (1) Carry out infrared ...

Embodiment 2

[0057] Using liquid chlorine, carbon disulfide, and dilute hydrochloric acid (12%) as raw materials, use a high-pressure pump to pump them into the microchannel reactor under pressure, wherein the flow rate of liquid chlorine is 0.595L / h (12.0mol / h), and the flow rate of carbon disulfide is 0.150L / h (2.5mol / h), the hydrochloric acid flow rate is 0.536L / h, the reaction temperature is controlled at 15±1°C, the reaction pressure is 1Mpa, and the residence time is 1.5min. The raw material enters the pressure storage tank after the microchannel reaction is completed, and the content of carbon disulfide in the oil phase is less than 3% after sampling and is considered as the completion of the reaction. 447.4g of the product was obtained by continuous production in one hour. According to the detection method of Example 1, the effects such as content and yield of the product were tested, and the results are shown in Table 2.

Embodiment 3

[0059] Using liquid chlorine, carbon disulfide, and dilute hydrochloric acid (12%) as raw materials, use a high-pressure pump to pump them into the microchannel reactor under pressure, wherein the flow rate of liquid chlorine is 0.657L / h (13.2mol / h), and the flow rate of carbon disulfide is 0.150L / h (2.5mol / h), the hydrochloric acid flow rate is 0.536L / h, the reaction temperature is controlled at 15±1°C, the reaction pressure is 1Mpa, and the residence time is 1.5min. The raw material enters the pressure storage tank after the microchannel reaction is completed, and the content of carbon disulfide in the oil phase is less than 3% after sampling and is considered as the completion of the reaction. 458.2 g of the product was obtained by continuous production in one hour. According to the detection method of Example 1, the effects such as content and yield of the product were tested, and the results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com