Method for removing floating slurry at pile head of cast-in-place pile

A cast-in-place pile and laitance technology, which is applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of easily damaged pile head reinforcement, long concrete cycle, labor and material consumption, etc., and achieves good construction stability and short cycle. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

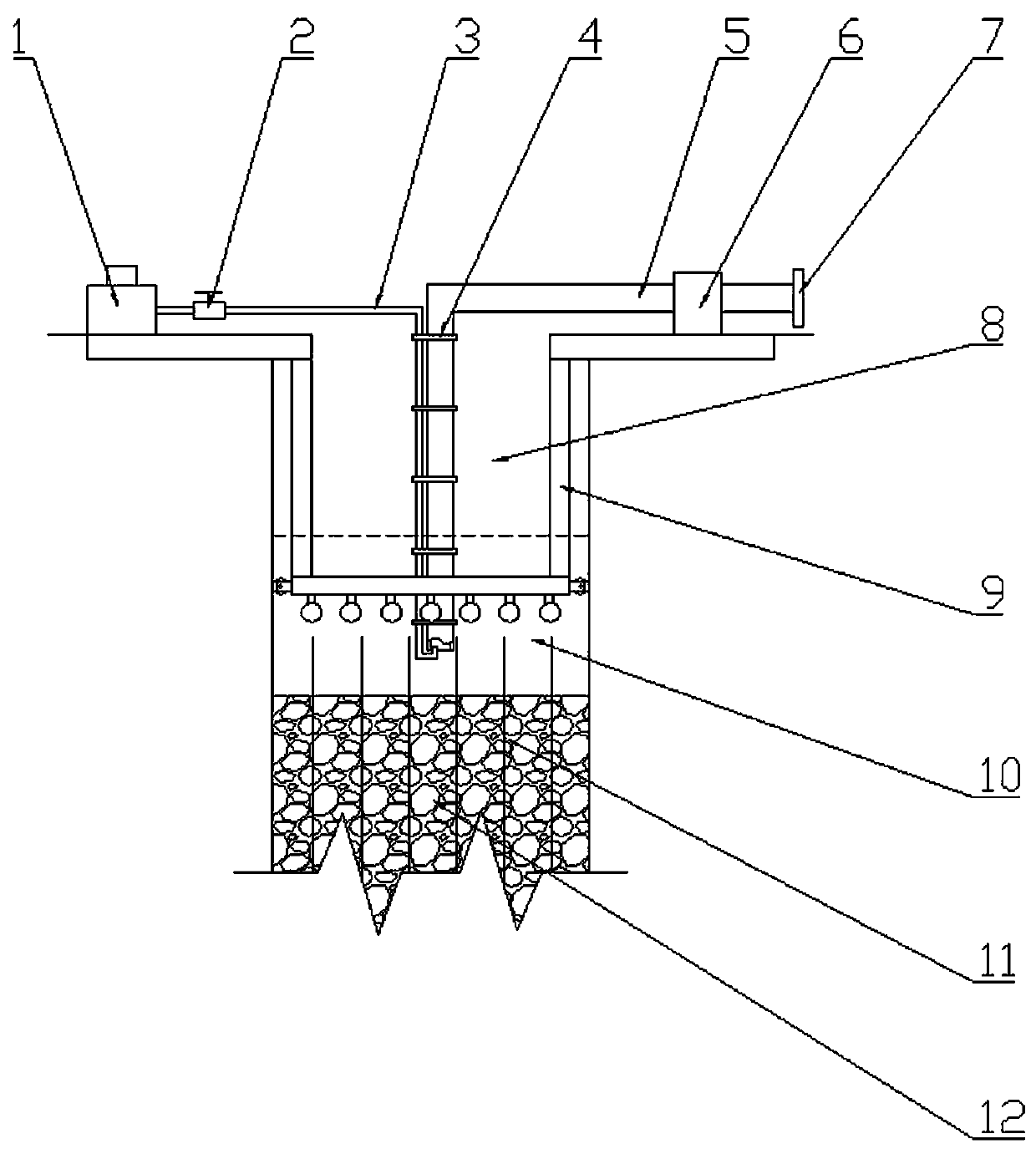

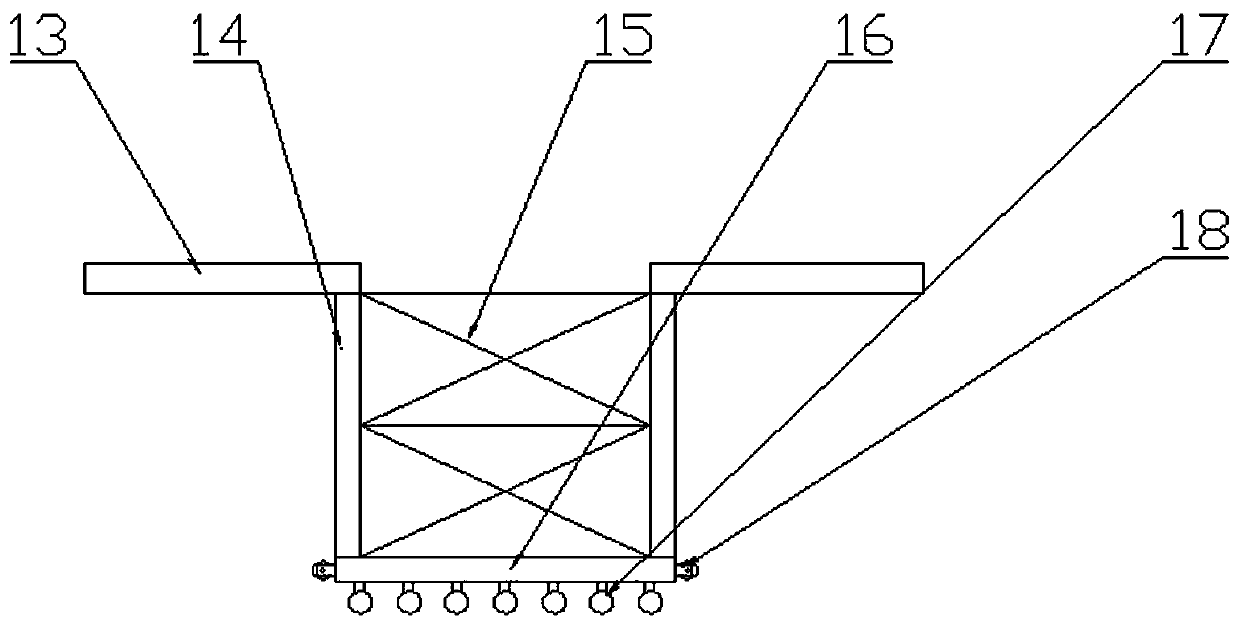

[0030] Embodiment: As shown in 1-4, a method for removing pile head laitance from cast-in-situ piles includes the following steps:

[0031] Step 1: Drill out the pile hole 8 first, then put the pile steel bar 11 into the pile hole 8, then pour concrete so that the middle and lower parts of the pile hole 8 are filled to form the pile body 12, and at the same time, the upper part of the pile hole 8 forms a layer of mud and concrete. Laitance 10.

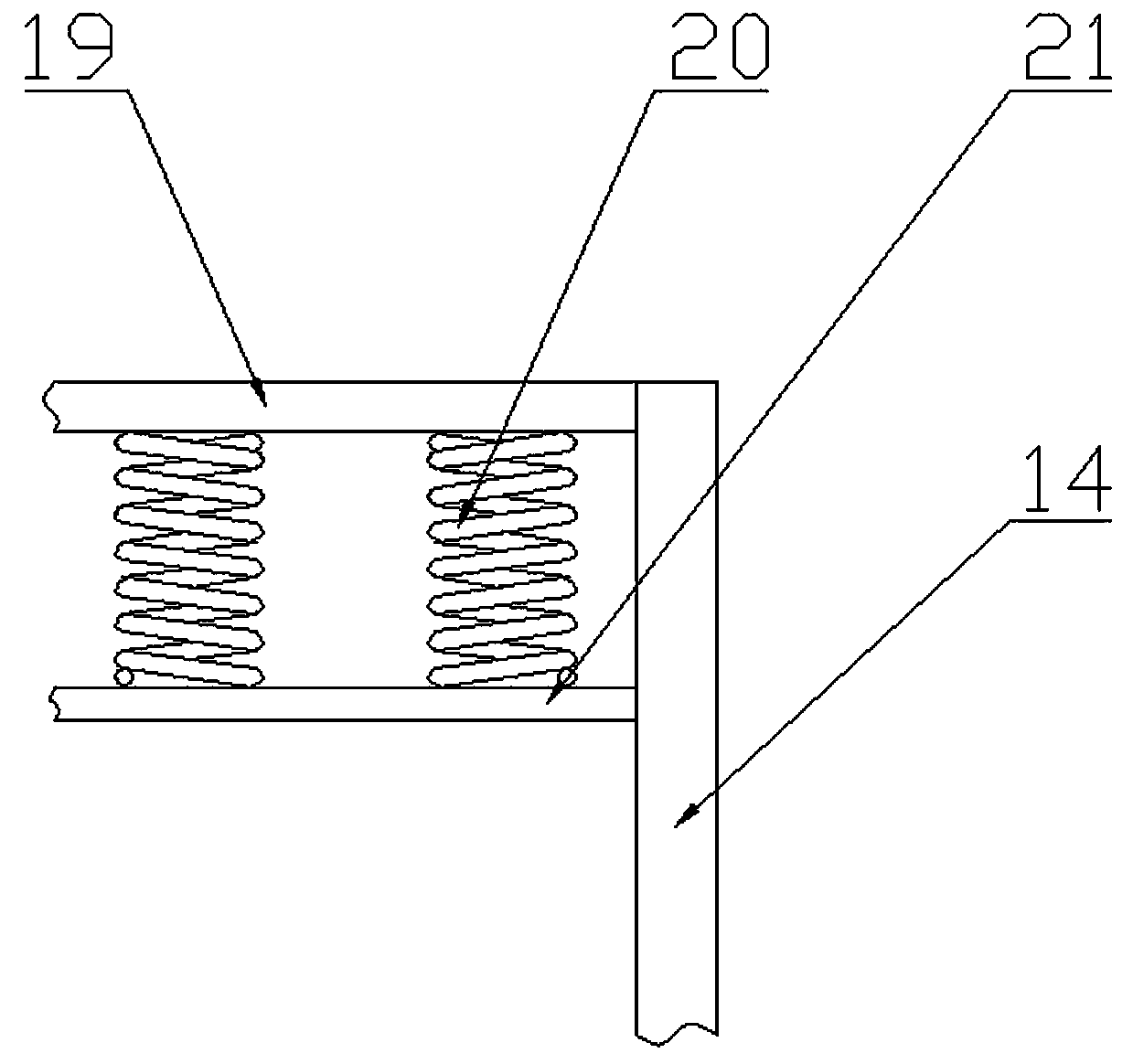

[0032] The second step: then place the floating frame assembly 9 fixed with the slurry discharge pipe 5 and the high-pressure air supply pipe 3 into the pile hole 8 so that the lower ends of the slurry discharge pipe 5 and the high-pressure air supply pipe 3 are immersed in the floating slurry 10 . The high-pressure air supply pipe 3 is hooked into the lower port of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com