Novel rigidity landfill anti-permeation structure and construction method

A construction method and landfill technology, applied in infrastructure engineering, protective devices, buildings, etc., can solve the problem of not being fully applicable to storage of industrial solid waste and hazardous waste, leaks that cannot be detected and processed in time, and rigid landfill protection. Infiltration structural welding and other issues to achieve the effect of reducing leakage risk, avoiding incompatibility, and preventing environmental pollution accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

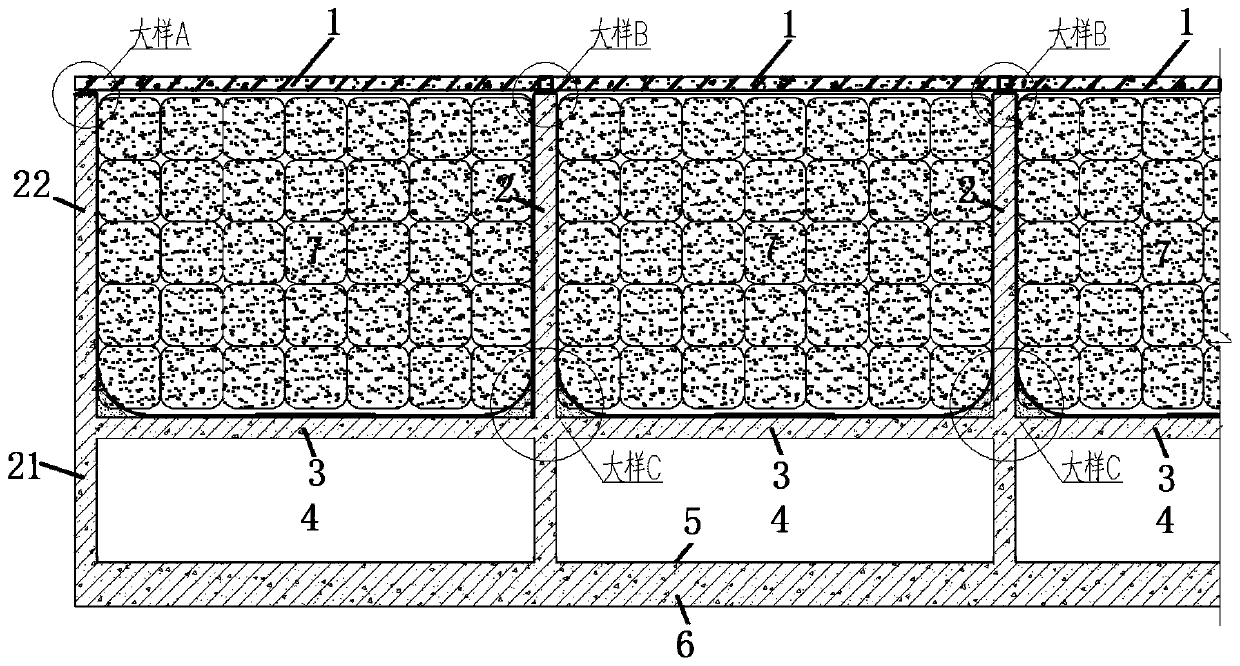

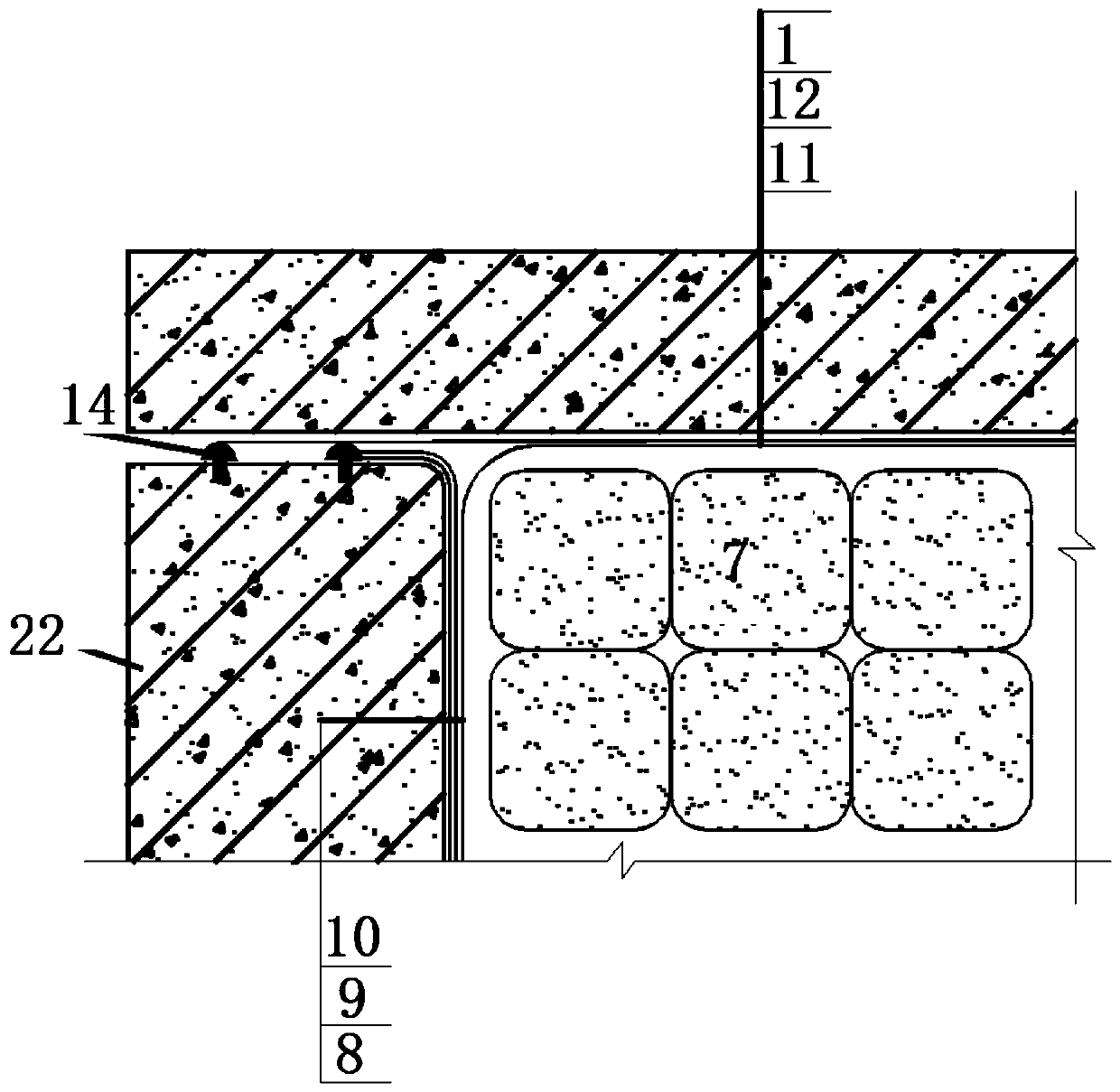

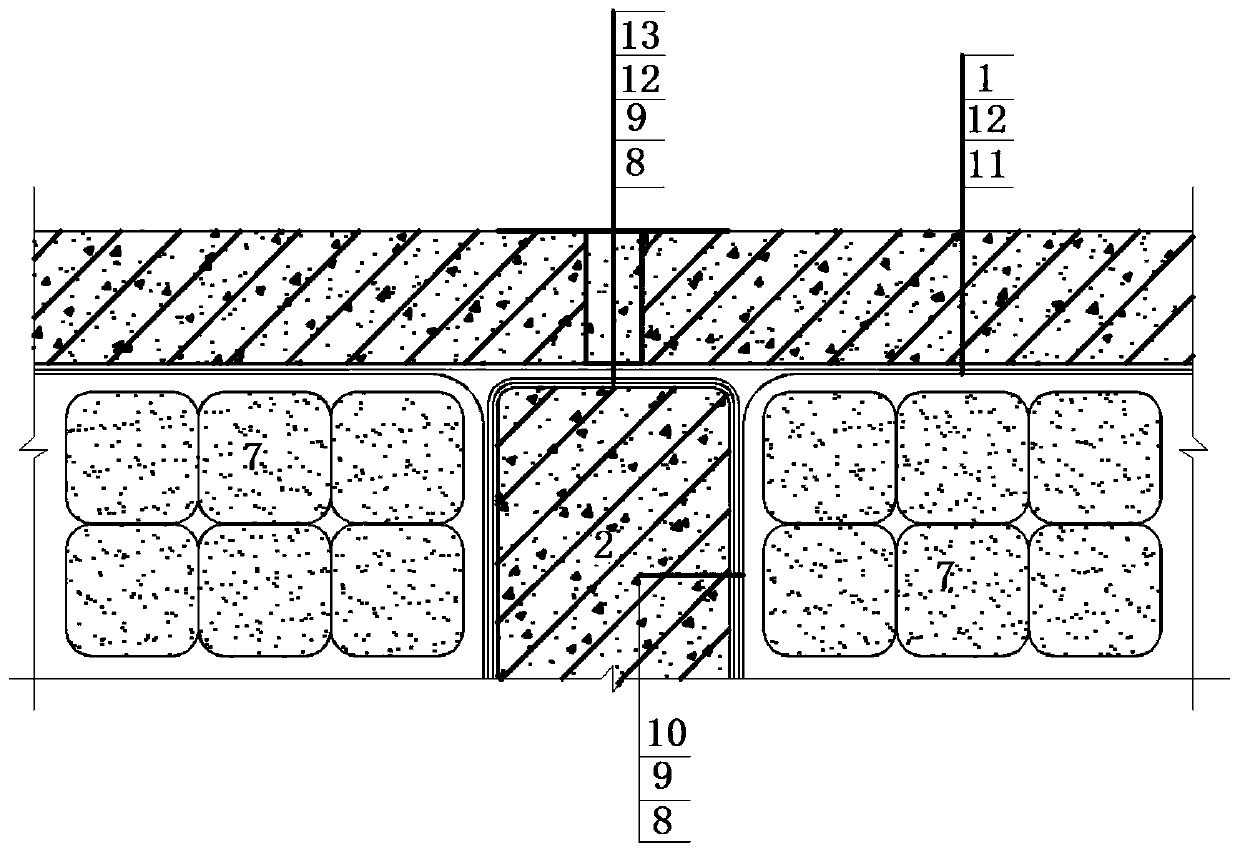

[0043] (1) The anti-seepage structure of rigid landfill in the present invention comprises the flexible anti-seepage structure of reinforced concrete rigid landfill tank structure, inner lining and industrial solid waste or dangerous waste 7 to form, and wherein reinforced concrete rigid landfill tank structure and inner lining The flexible anti-seepage structure and the two together form a five-layer anti-seepage system.

[0044](2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com